Products

NX Case Study – Award-winning vehicle manufacturer cuts cycle time by 80 percent with help of NX

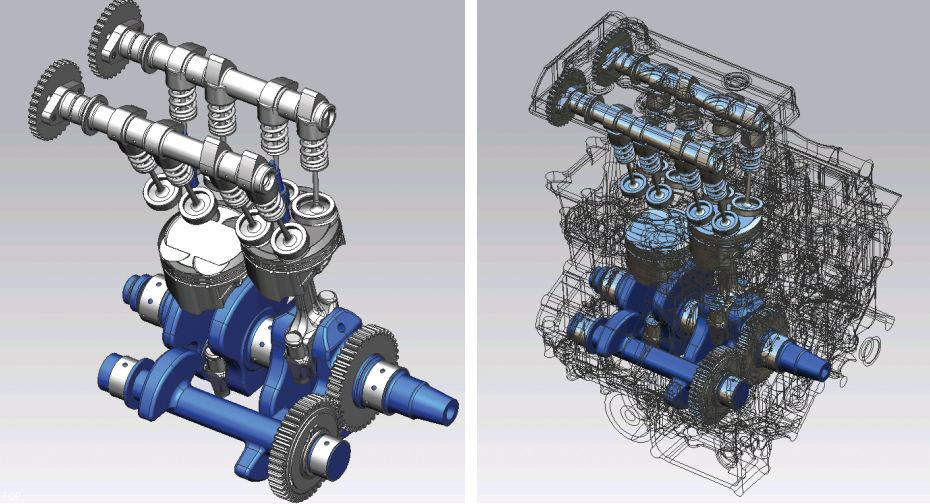

Siemens PLM Software NX solution helps Sanyang engineers focus on creating value

Challenges:

- Identify easy-to-operate 3D modeling technology with intuitive interface

- Improve the accuracy and efficiency of curved surface processing

- Use 3D CAD software to increase the precision of part dimensions

Keys To Success:

- Introduce digital product development program to improve accuracy

- Improve the efficiency of design simulation and model disassembly

- Leverage the professional services and technical support of the Siemens PLM Software partner

Results:

- Reduced the cycle time from design to engineering by 80 percent

- Enabled engineers to focus on creating value

- Improved accuracy of dimensions

- Increased the speed at which models can be produced

- Enabled inexperienced designers to be productive faster

Industry:

Client’s Primary Business:

Sanyang manufactures and sells motorcycles and automobiles. Founded in 1954, it is the only enterprise in Taiwan that manufactures both kinds of vehicles. It also produces all-terrain vehicles, scooters and motorcycle engine components, including pistons, cylinders, crankshaft components, cylinder heads, mission gears and crankcases.

Jerry