Northwestern Engineering Students Bring Elementary Kids Drawings to Life

Meet Nora the dragon.

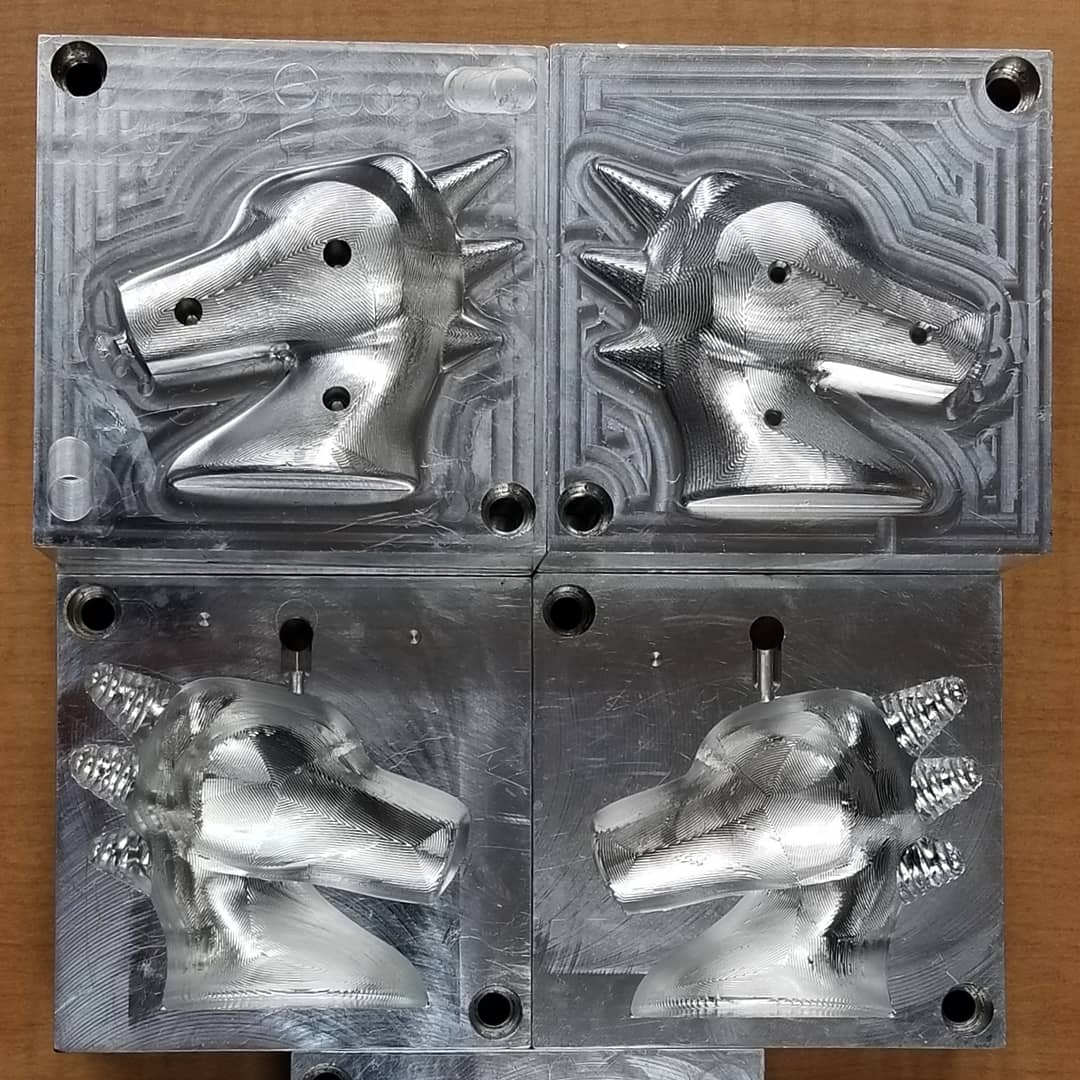

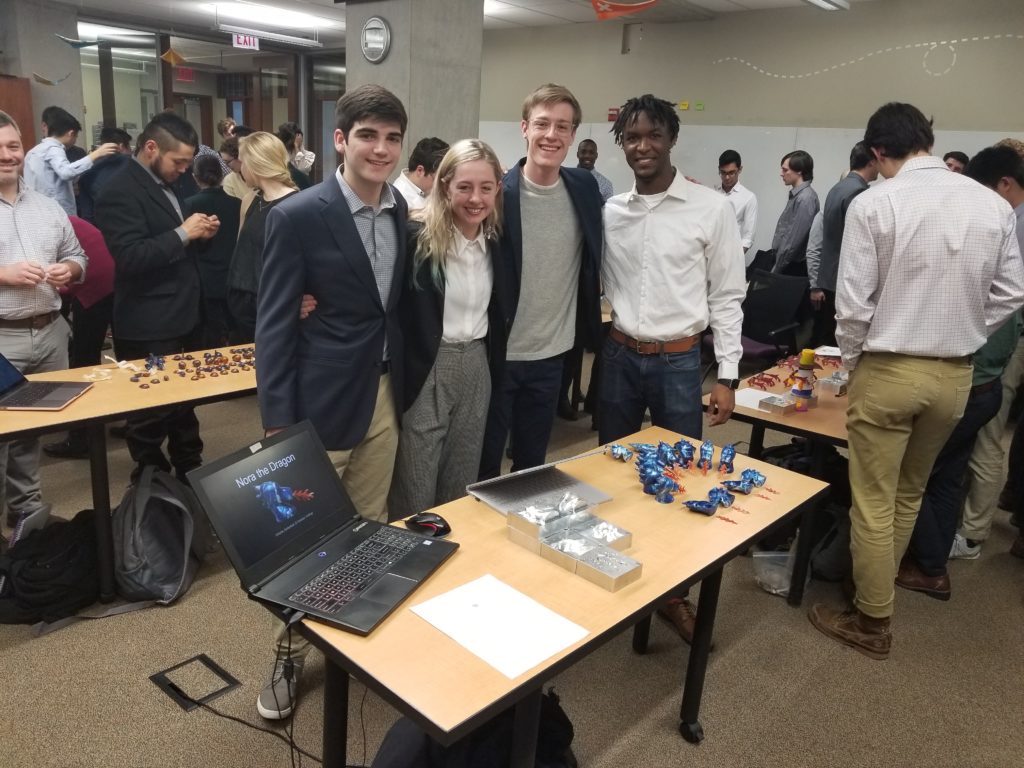

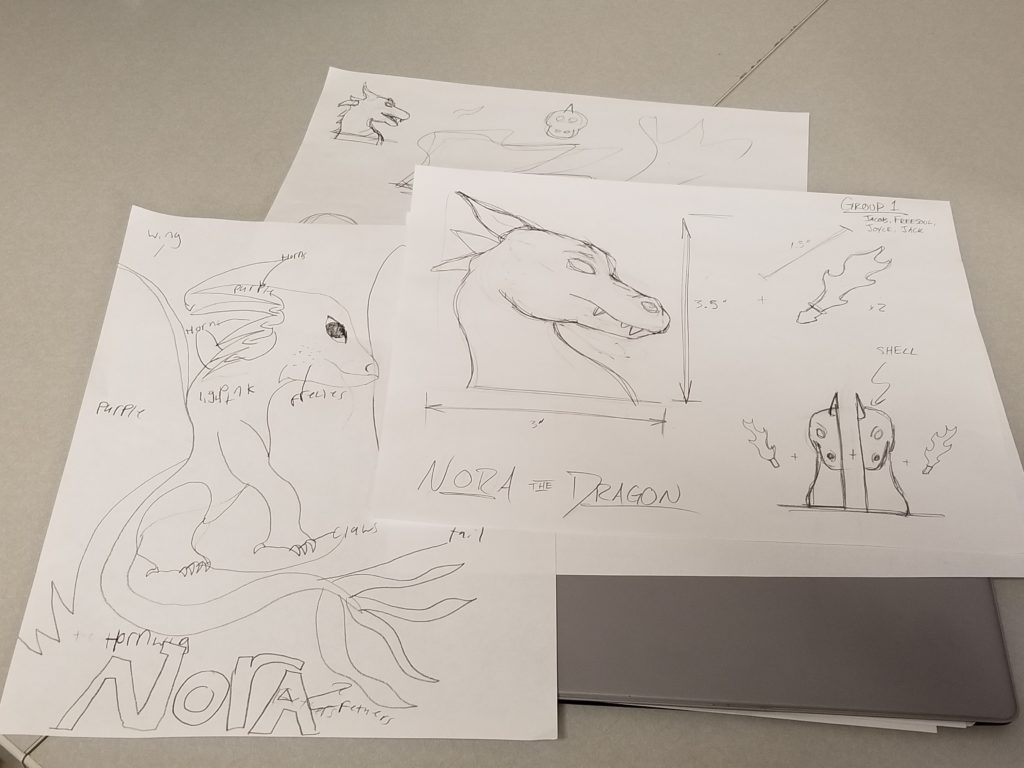

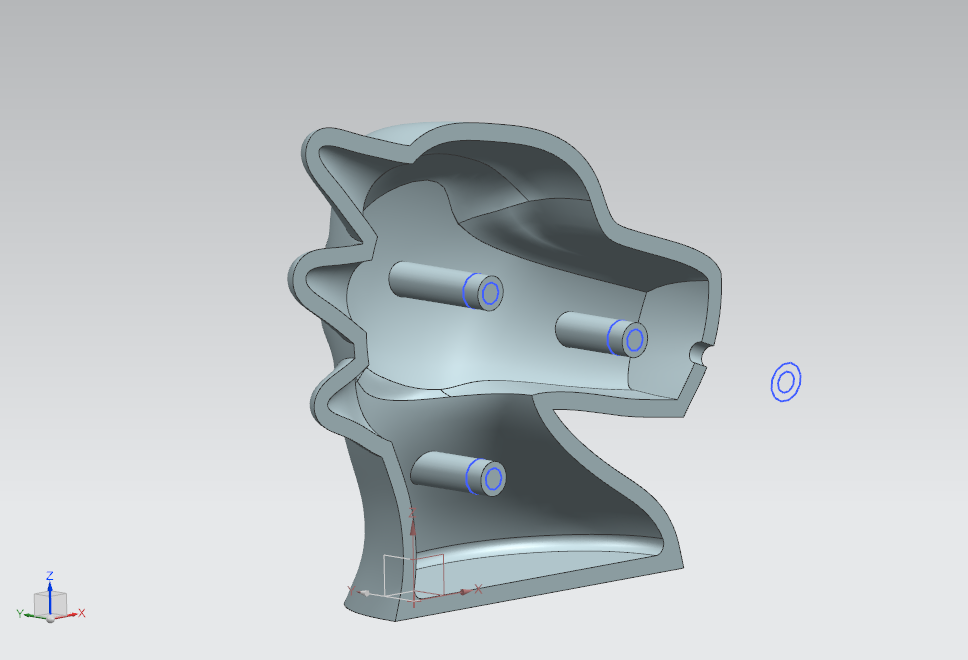

Nora was brought to life by Northwestern engineering students Jack Eichenlaub, Joyce D’Aprile, Jake Hullings, and Freesoul El Shabazz. These four students won their class team project ( Computer Integrated Manufacturing II: CAD/CAM ) The students were tasked with designing a children’s toys based on drawings from fourth graders at Lincoln Elementary, Evanston. The conceptual design went from CAD model, to CAM program, to CNC-milled aluminum mold parts, to a multi-component plastic injection molded toy. The final product was judged alongside 17 other teams with Nora coming out on top. It’s amazing to see what 4 college students can create in just 10 weeks with the right tools like NX.

It’s pretty remarkable to think that you can take drawings from 4th graders at a local elementary school and bring it to life.

“We put a lot of time and effort into the project, but we were enjoying ourselves. We are super happy with our final result “

We wanted to get more insight on the process and details among each of these engineers. Please see below for more images of the project as well as a response from Jack Eichenlaub who was one of these brilliant students.

Jack Eichenlaub :

- Name and what you are studying at Northwestern?

I’m John Eichenlaub, but I go by Jack, and I’m a third-year student studying Manufacturing and Design Engineering at Northwestern! (and also the Segal Design Certificate and a French minor, if that matters).

- What do you hope to do once out of University?

Ideally, I’d get the chance to work in the automotive or industrial design sector. I have a passion for cars and design, but I have an engineering background and skillset. I’d like to be able to move fluidly through both worlds with a boutique/small volume manufacturer to both design and engineer vehicle interiors. I think driving is one of the greatest experiences imaginable, and to help people feel the same passion by improving their driving experience through intuitive design would be very fulfilling.

- What is this design competition that you’ve participated in?

Our team was part of the Mechanical Engineering 340-2 course, which was Computer Integrated Manufacturing course here at Northwestern. The entire class was formed into separate teams and challenged to design a part to be injection molded, then follow through and create the molds and parts using NX CAD and CAM.

- How was it working together as a team to accomplish your winning design?

Working in a team is never the same exact process, but this specific project was benefitted by complementary skillsets in all members. Some were much better at surfacing and initial design in NX, and others had previous experience operating the Haas CNC machines. One thing that stuck out to me was that each team member was really invested in creating an exceptional final product, and everybody aligned vision for the project. That synergy was really useful when the hours got longer, and when we pushed the capabilities of our machines and time.

- Can you walk us through your design and manufacturing process?

Our process started with receiving a set of drawings from local area 4th graders, and we were tasked with “interpreting” one of them to then model, mold, and plastic inject to bring it to life! We selected “Nora the Dragon” and set to work! We surface modeled the neck, head, and horns of the dragon to match more detailed sketches produced by Jake. After that, we received feedback from the instructors and fiddled with the model until we got appropriate draft angles and rounded corners on our part. From the outset, we knew we would be limited by our smallest available tool (1/16th diameter and 1/8th inch long), so this influenced our design process. After the part was finalized, we used the WAVE geometry linker and some mold blanks to create CAD files for the molds. These molds were then directly used with NX CAM to create all of our toolpaths and CNC programming! Written here it sounds simple, but this was very much an iterative process with tons of back and forth between the steps, and many many iterations of part design. We should also mention that we screwed up a few mold blanks from silly zeroing errors or misplacement of the WCS within NX. All great learning experiences!

- Has your CAD experience grown with this project and software used? If so, how?

Absolutely! I came into this project not knowing surfacing in NX (only Solidworks) and having never touched the CAM elements, and I left feeling confident I could repeat everything we did as a team on my own! I think it was great to learn by doing, and to have teammates willing and able to correct each other’s mistakes as we developed our programs. I was particularly glad to have gained experience with the CAM side of things, as I’m already taking this knowledge and applying it to assemblies for my design capstone project this quarter!

- How does NX compare to other software’s you’ve used?

I have used NX, Solidworks, Fusion 360, and a bit of Catia v5, and in many ways, I prefer NX to all of the rest. I can only fairly compare it with Solidworks because I have equal experience with the two, but I find the solid modeling aspect easier in NX. I prefer the way extrusions work and the geometric constraint menus. I really can’t say enough about the integration of NX CAD and CAM, as it was super intuitive for a first-time user. We had instruction from our professors, but I was definitely able to be effective with the software and use it after only an hour or two of learning.

- How did you find NX valuable in everything from the design to manufacturing process?

Its pretty clear that without NX, we would not have been able to do this entire project! Having everything operating within one program with common menus and function made everything much easier to comprehend. We were able to use the evaluate tools within NX to verify our dimensions such as wall thicknesses and corner radii, which was great to use after we had to modify our part so many times.