Visualization and the digital twin for AEC and BIM

In the first part of a three-part series on technology in the architecture, engineering, and construction (AEC) and building information modeling (BIM) industry, our host Jennifer Piper talks to Derek England, the NX Product Manager for AEC and BIM at Siemens Digital Industries Software, about why technology advances have been relatively stagnant over the past few decades in AEC and BIM.

In this episode of the Next Generation Design podcast, you’ll learn why the construction industry lags in per-person productivity improvement. You’ll also learn about some of the latest technologies introduced in the AEC industry and the gaps they are expected to fill. Additionally, you’ll hear about how the digital twin is applied in the AEC industry.

Listen to or read the full episode: Integrating the Metaverse and BIM CAD tools into the AEC BIM Industry

What you’ll learn in this episode:

Challenges facing the construction industry

Construction projects have very thin margins, so they must be efficient and on-budget, with all people and activities thoroughly coordinated and aligned. Currently, there is a lot of user error and inefficiencies that lead to project overruns and delays. It is important to adopt tools and technologies that have become available to reduce these errors and inefficiencies.

Latest innovations in the construction industry

Derek mentions that there are many new technologies that help on-site of a construction project. There are 360-degree cameras, drones, robotic dogs—all to help scan worksites. Then, there is virtual reality which helps stakeholders to visualize the final result and be involved in the design early.

How Metaverse impacts the construction industry

Derek then talks about a big recent innovation in technology, the metaverse. The metaverse allows all kinds of visualization that was not accessible before. The metaverse gives infinite space to explore. Someone can see a theatre from multiple different views, you can explore worlds that you may not be able to see in-person.

A use case that makes Siemens’ NX stand out

Derek has been working in his role for 25 years. When talking to customers, he often realized that they were using our products for AEC and BIM, even though it was not a typical BIM tool. NX was being used for bridge design, tunnels, railways and more.

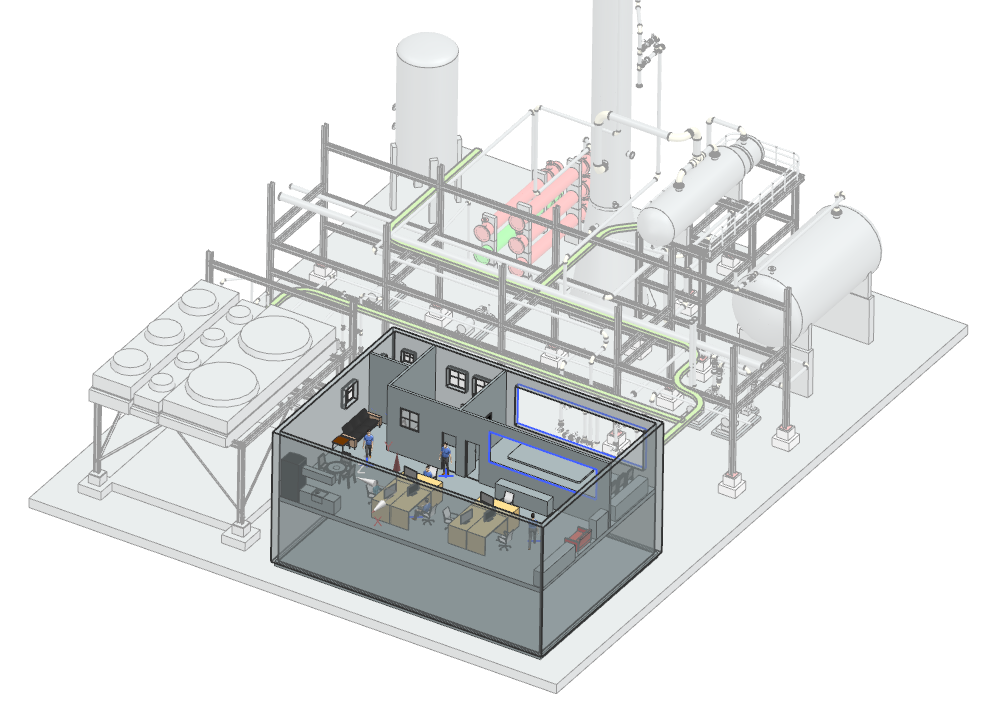

Max Bögl, a construction company in Germany, realized how their designs were too complex for the solutions they were using, and needed a more integrated set of tools. Starting with NX for Manufacturing, they soon realized how they can use other solutions from Siemens Digital Industries Software to create a comprehensive digital twin and digital thread. The integration products such as NX for Design, NX for Manufacturing, and Teamcenter creates the ultimate BIM solution for construction companies.

How integrated multi-discipline Building Information Modeling (BIM) works with the digital twin

In the AEC and BIM industry, many individual, disparate solutions and software are used for specific workflows, but they do not all integrate and work together. However, this is not efficient when the building aspects themselves must be integrated and connected. Derek compares this integration to how a building has fire sensors, plumbing for fire suppression, sensing whether doors are opened or closed, etc. These all must be connected, so it would make sense that the tools used to build and design these are connected as well. Yet, this issue has only recently been highlighted in the last 6 months with how it creates a lack of productivity and ability to simulate building properties and functions working together. Siemens, NX, and the digital twin address this issue.

BIM captures the data all in one location with the information needed to flow downstream. The digital twin enables the loop-back mechanism. Projects in the construction industry often make the same mistakes over and over again due to a lack of input of lessons learned from each design project. But with the digital twin, issues and fixes found in the construction project can be input back into the original design so that future projects will avoid the issue reoccurring.

The digital twin also prevents issues from occurring since it allows the physical world to be simulated in a digital risk-free space. You can find an issue in the digital twin and find out what is causing the issue and what it impacts and fix it before it ever reaches the real world. Meanwhile, the digital thread enables all the learned information to flow between all applications. If different applications are being used for different workflows, a digital thread ensures that everyone is working on the most up-to-date version of a design.

While this episode of the Next Generation Design podcast focuses on how tools work together, the next episode in the three-part series will discuss how people work together in AEC and BIM with the design review process. As Derek says, “the whole process is only as good as your weakest link.”

Connect with Derek on LinkedIn

Connect with Jennifer on LinkedIn

Continue listening to the Next Generation Design Podcast here

Want to learn more about NX CAD software? Check out our website or try it for free.