Top 3 Challenges Companies Face When Updating Their Mechanical CAD Solutions

Engineers rely on their mechanical CAD solutions to create innovative product designs. And solution providers are constantly updating their offerings with new features and additional modeling capabilities to improve user productivity. To tap this new functionality, however, existing CAD users have to get up to speed on the latest version quickly. But a number of common challenges stand in their way.

Getting Up To Speed with New CAD Release

When a provider releases a new version of a mechanical CAD solution, the update contains new capabilities that may affect modeling, drawing, automation, rendering, or data management. Many of these features can improve the productivity of design engineers who rely on CAD for their work. But this is only the case if those engineers can quickly master new features and options.

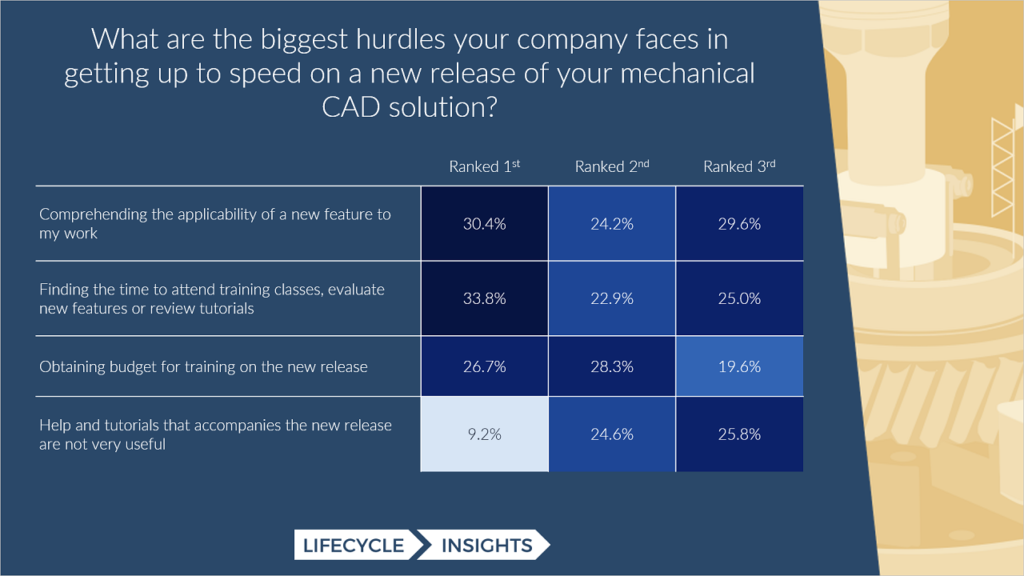

Design engineers face myriad challenges when trying to familiarize themselves with new releases. Lifecycle Insights conducted a research study to gain insights into these obstacles. The results show that design engineers are affected by three main hurdles; lack of time, lack of budget, and the inability to relate the new features to their design work.

Time for Training

Training can help design engineers learn about the new CAD capabilities and how to use them. About 89% of survey participants noted that they need the training to learn to use new capabilities effectively. Today, engineers have access to several modes of training: live in-person training, live online training, and self-directed learning. While many self-directed learning formats are available for no cost, other, more popular training formats come with a price tag.

Even if companies have the budget for training, design engineers report they simply do not have the time for it. About 34% of respondents noted they did not participate in new release training because of a lack of time.

There are several possible explanations for this statistic. First and foremost, today’s engineers are working under constrained development schedules. They are focused on getting the product designed, not learning about new features. Second, many engineers also need to get involved in solving critical issues, troubleshooting manufacturing problems, managing change orders, and other product development issues that have nothing to do with design.

The survey findings are clear: Design engineers, likely for many reasons, are finding it difficult to allot time for training when they receive the new version of their mechanical CAD solution. One fix is to take on-demand online training for specific features at the time that the user actually needs to access them for work-related tasks. By utilizing this “just in time” approach, engineers can minimize their time away from the job and receive targeted, capability-specific knowledge.

Budget for Training

As noted above, many training options for mechanical CAD solutions come at a cost. While design engineers can harness on-demand online training to minimize time away from work, they may not have the budget.

Lack of funds is one of many significant challenges design engineers face when dealing with solution updates. More than 50% of research participants said they would prefer face-to-face training — either online or in-person — with a knowledgeable instructor. This would allow them to ask questions related to their application areas and customize the training to suit their specific needs.

Paid training, however, requires budget approvals. More than one-quarter of study respondents stated that budget is the primary obstacle to getting up to speed on new release capabilities. No doubt, today’s manufacturers are operating under tight financial restraints. As a result, many organizations have a hard time approving out-of-cycle funding for training. Engineers must find a way to reserve funds for training during financial budgeting. The trouble is that financial budgeting may not coincide with new releases and the applicable training options.

To address challenges like this, organizations can buy training subscription services. In this scenario, companies pay a flat, recurring annual fee that can be easily incorporated into annual budgeting. The other benefit to this approach is that engineers can also access a vast peer network in online communities. This helps them gain specific knowledge about new features and troubleshoot potential problems as they start to master the new release capabilities.

Relating New Features to Design Work

Time and budget constraints mean design engineers must target their training to what they need for their particular work. Every new release of a mechanical CAD package comes with a variety of new features. Yet, not every feature is relevant for every engineer. Depending on the types of products they design and their specific duties, only certain capabilities will be useful to them. Therefore, it is not surprising that only 16% of survey respondents said they felt a compelling need to use new features from a CAD update for their current design needs.

In contrast, more than 30% of research participants stated they did not see the applicability of new CAD capabilities to their specific work. This, too, was a top hurdle in getting up to speed on the new release. After all, engineers have to understand what a new feature does before they can apply it to their work.

One way users can gain knowledge about new capabilities is to watch product update sessions offered by the mechanical CAD solution provider. These often take place at yearly conferences held by the solution provider. In addition to these sessions, engineers can rely on product review articles or watch online videos available in the public domain to help deepen their understanding of new functionality. These events and materials can give engineers a quick overview of what’s new without a significant time or cost commitment. If a new feature seems relevant to an engineer’s role, he or she can always take a deeper dive with feature-specific training or a free tutorial session to learn more.

Conclusion

There are a variety of challenges that engineers may face when their mechanical CAD solution delivers a new release or update containing new features and capabilities. The three most significant hurdles to getting up to speed on new releases are limited time, limited budget, and a limited understanding of what new capabilities are most relevant to their work.

There are several ways that engineers can overcome these challenges. By adopting on-demand, subscription-based training and participating in product update sessions, companies can get their engineers up to speed quickly without a significant time or cost commitment. As a result, these CAD users can make the best use of innovative new functions that enable top-notch design work.