Hackrod Challenges Traditional Manufacturing with NX

New and innovative. Two words we love to hear. For those of you who haven’t hear of Hackrod, they are a digital manufacturing company that uses new methods of design for the next generation of automotive technology.

To achieve their goal of democratizing engineering design and manufacturing, Hackrod will be using NX, the next generation design platform. Hackrod will create the world’s first car designed in virtual reality, engineered with AI and 3D printed, full size, in structural alloy. The ‘La Bandita’ speedster is intended to serve as proof of concept for an entirely new industrial design to production methodology.

By utilizing NX design, simulation and manufacturing solutions, Hackrod now has access to the latest design and engineering tools to rapidly design, test and manufacture transport solutions without the need for massive industrial infrastructure or tooling budgets.

By utilizing NX design, simulation and manufacturing solutions, Hackrod now has access to the latest design and engineering tools to rapidly design, test and manufacture transport solutions without the need for massive industrial infrastructure or tooling budgets.

Generative design in NX will allow Hackrod to process and create many new design options that weren’t previously possible. By utilizing tools such as Convergent Modeling™, topology optimization, lattice structures and NX Realize Shape™ for industrial design & styling in NX CAD, Hackrod has created a unique chassis and suspension components that are lightweight yet structurally sound.

The innovative toolset in NX contains design for additive manufacturing features not present in other systems. Design checkers, lightweight lattice structure design, and the ability to scale up from prototypes to full production will enable Hackrod to build their custom parts from the ground up with exact specification.

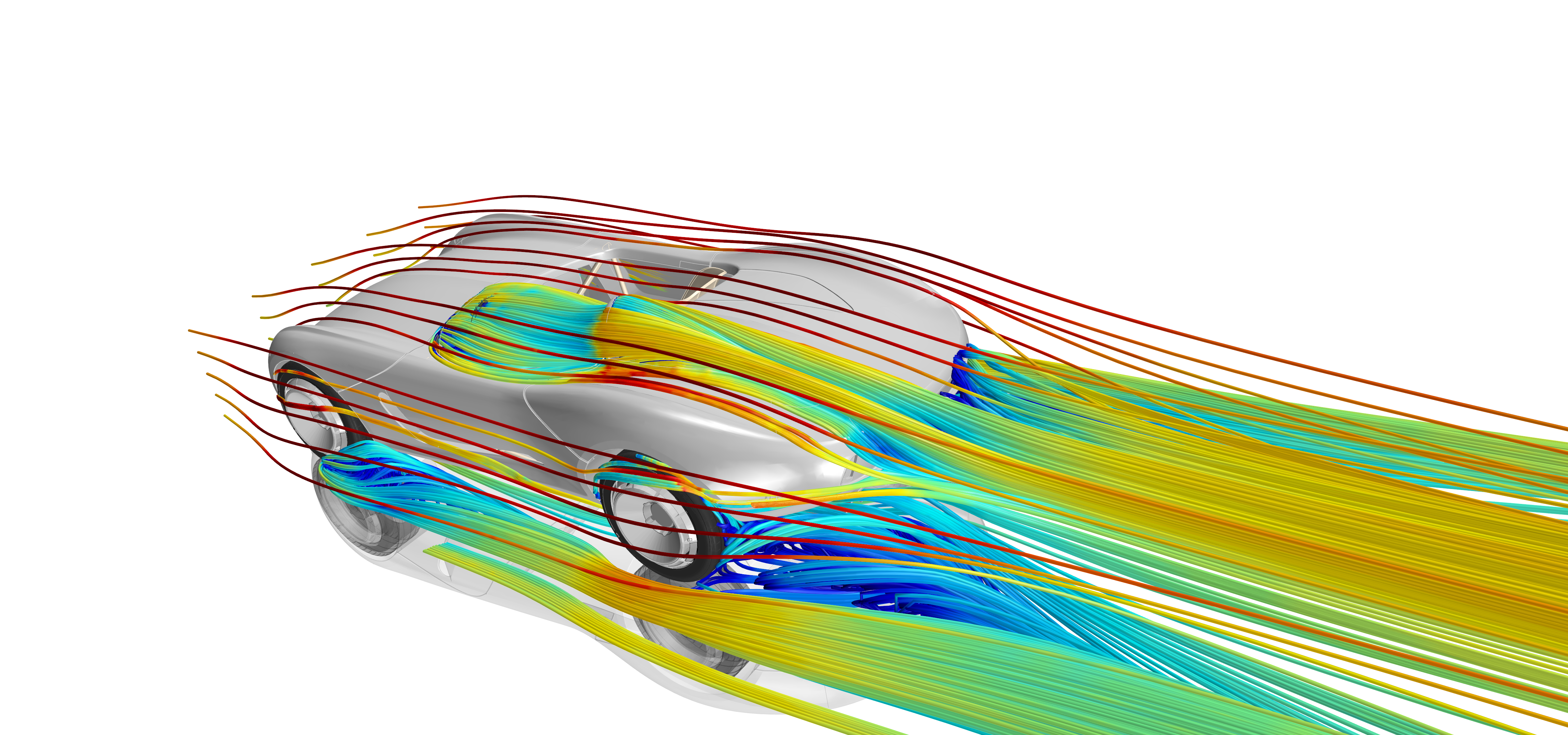

Perhaps the most exciting part of Hackrod (aside from the actual vehicle) is the process in which they test prototypes. Hackrod will be utilizing the virtual testing capabilites within Simcenter to acheive their precise visualization goals.

visualization goals.

The broad, integrated capabilities of NX for additive manufacturing from design to 3D printing with the ability to scale up from prototypes to full production will enable Hackrod to build their custom parts from the ground up with exact specification.

We are looking forward to working with Hackrod on this exciting journey.