NX Case Study: FUNCOSA

The technical team at FUNCOSA works more accurately and rapidly using NX CAD. “We’re saving a lot of time using NX, and find it useful because it supports multiple design approaches,” says Víctor Fernández, director of process engineering. “NX is responsive, enabling you to handle various parts with ease. I have never found a project that could not be addressed using NX.”

Challenges:

Limitations of 2D design on crucial, complex parts

Quality and deadline targets

Difficult, unsecure access to project documentation

Environmental protection, safety and innovation

Keys To Success:

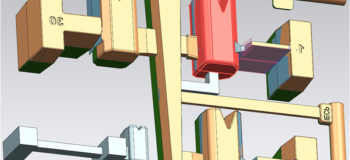

Advanced 3D design

Synchronized CAD/CAM

Integrated project lifecycles

Results:

Enabled new business opportunities while enhancing current customer relationships

Significantly reduced design and manufacturing time

Essentially eliminated use of paper

Provided collaborative environment

Reduced errors while avoiding costs

Industry:

Industrial Machinery & Heavy Equipment

Client’s Primary Business:

Fundería Condals (FUNCOSA) is a foundry specializing in the production of medium and large series of melted gray and ductile iron castings. Founded in 1976, the company is internationally known for providing high-quality parts to various industries such as automotive, railway and hydropower.

Solutions/Services:

Client Location:

Barcelona

Spain

Read the full case study.