NX for Students | Enhancing Future Employability and Getting NX Certified

As a student engineer or designer, we are filled with creative ideas. Learning NX as a tool for all stages of your design process can help you bring these ideas to life, during university, and beyond with a single software.

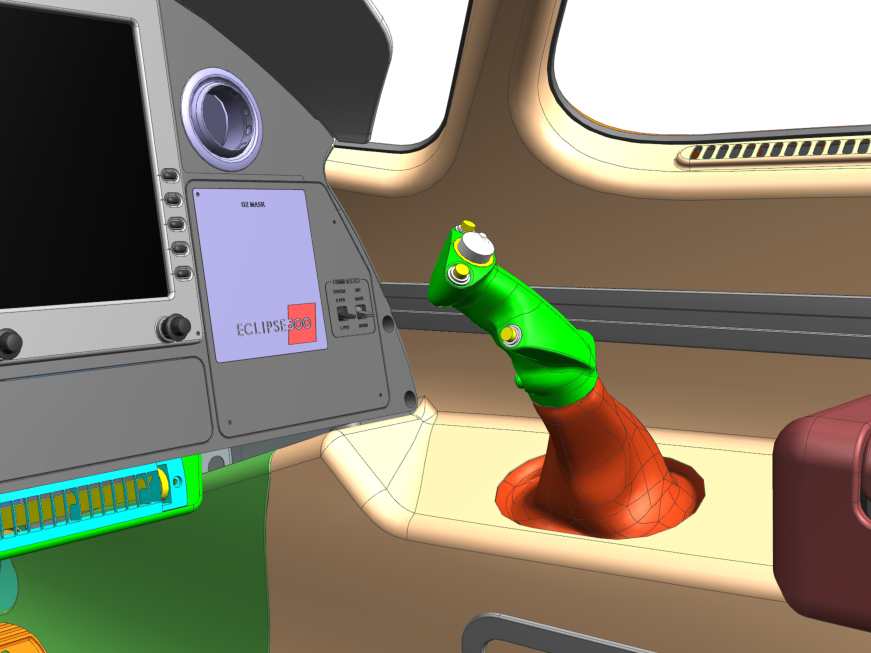

In July I started a placement as a Marketing, Visualization and UX Design intern. The first part of this role was to learn how to use NX™ software over a period of 4 months. I think learning NX is a useful tool to have in your skillset, especially if you are an industrial design or engineering student. NX provides versatile and extensive modelling capabilities to help bring your initial designs through to high quality prototypes and renders. It can create a comprehensive digital twin from the beginning of your design process to the end. This can include: modelling, simulation, animation, visualization, help with manufacturing processes and a collaborative virtual reality experience.

It is also important for me, and other students to look at this from an employability perspective. Being a certified NX user has huge advantages, as it is used by major companies across design, manufacturing, and engineering industries – from NASA to Unilever. It therefore opens many doors to career opportunities, alongside developing a valuable skillset that can be transferrable to other CAD systems.

How can NX help me be more creative when designing?

I was invited to demonstrate some of the skills I had learnt along the way at Loughborough University as part of Siemens Software Student Connect in November 2022. I think it is beneficial to have other students share their knowledge and workflows in NX, as they have direct knowledge of how to help others working on similar projects. Each skill I aimed to teach was a skill I could directly picture benefitting a project I had previously worked on. As I only learnt to use NX a few months prior I also tried to identify which skills I found hardest in the beginning, in order to explain them in more detail in the masterclass. I reflected on what skills might have helped me the most in improving my design process, on top of what the NX certification taught me. One of the tools that stood out was the use of Realize Shape.

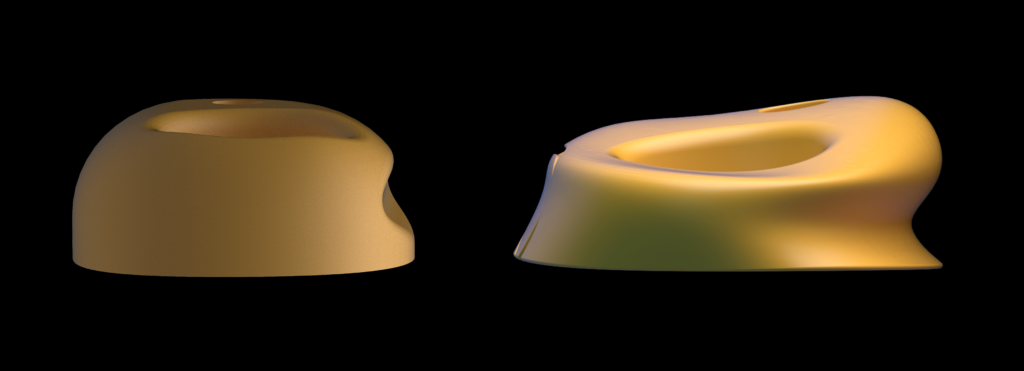

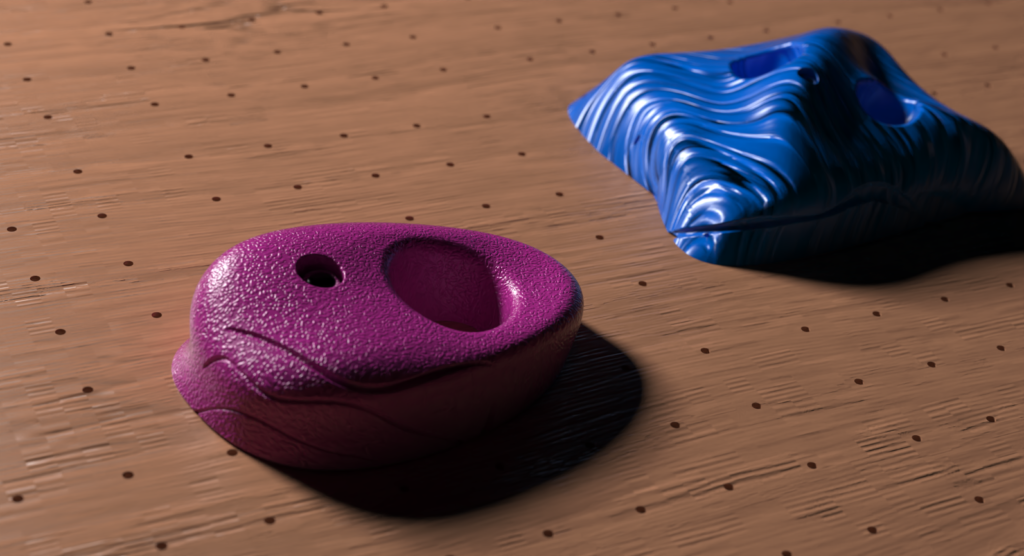

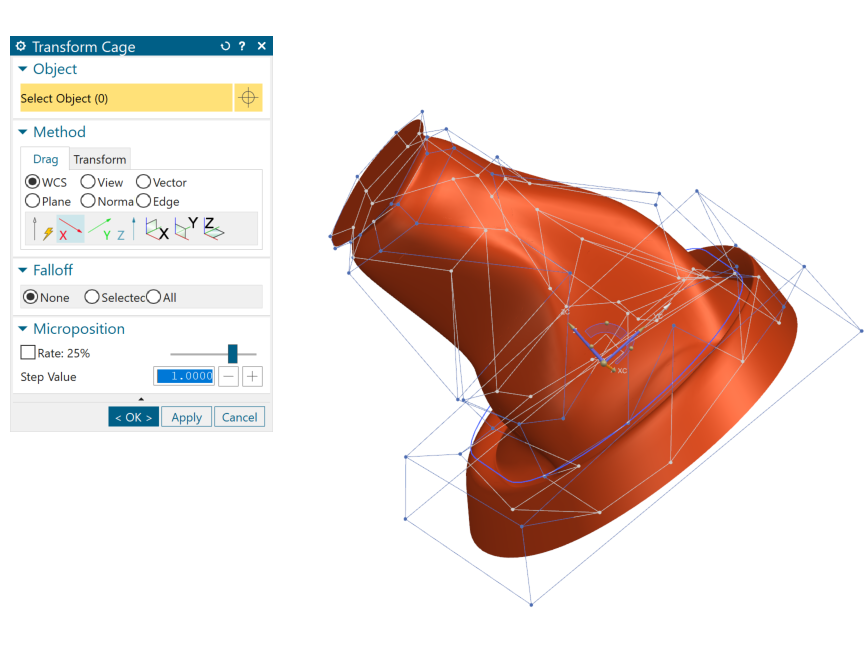

As a product design student, many of my projects and designs required having to model a complex, organic shapes, from my imagination. Given project time constraints, I would often have to resort to traditional parametric modelling techniques, which ultimately compromised my original intended designs. Realize Shape is a subdivision design tool, that allows you to manipulate the cage of a primitive shape. It can be used in conjunction with synchronous modelling features or as a tool on its own. Subdivision modelling (or polygon modelling) is not a feature that is unique to NX. However by using it within NX it skips the extra stages of exporting and importing different file types; instead allowing you to combine it with any surface modelling feature that NX offers. All the while, still being able to go back and edit the subdivision shape.

Whilst posing challenges with the creation of rigid product manufacturing information (PMI) within models, Realize Shape is an ideal tool for experimentation and prototyping, that does not require lengthy modelling processes, or wasted materials in physical prototyping. Another practical application is the creation of ‘soft’ material models. These are often the most difficult to replicate the organic curves of, and can become time consuming to figure out. With Realize Shape, however, you can quickly generate a model and make small and continuous adjustments to it in order to replicate the natural flow of a flexible material.

Creating realistic images of my designs in NX

The ability to render within NX allows you to visualize your product as your design evolves. Like polymodelling within NX, rendering is another function that has its own third party softwares. Staying within one software however, means being able to work simultaneously between parametric modelling and visualising within NX. Adjustments can be made whilst ‘live updating’ the final render, avoiding lengthy exporting times. It saves time on exporting those files, which can consume extra time and space on your computer. It also makes it as easy as possible to access rendering tools without learning additional software, streamlining the process. For companies, it creates a set of in-house tools, avoiding any outsourcing of other agencies to visualize their models. Since design processes are rarely linear, being able to switch between the two allows the designer to expand their workflow.

Where do I start with NX?

Whilst I picked up some skills I learnt in NX from those at Siemens and experimentation myself, the way I learnt most of my skills was through preparing for the NX Design Associate Certification. NX Certification validates knowledge of determining modelling strategies; creating & editing solid models, assembly models & structures; parametric vs non-parametric modelling techniques; and associative links between parts using NX design. Passing the certification earns you a badge which you can use on your resume, on LinkedIn, and showcase that you have acquired NX core design skills.

The best way to prepare for NX certification is the learning path on Xcelerator Academy. This learning path guides you through the essentials of navigating modelling, and assembling. This course is complimentary to you if your university is an NX academic partner. Siemens also offers complimentary three-month memberships from time to time, for example during the NX student day. Make sure to follow the Siemens LinkedIn group to get updates on free Xcelerator academy memberships.

I began this course with some CAD experience, but never had I opened NX. Following the course accelerated the rate at which I picked up NX, as it chronologically teaches you how to use it. It took me around 30-40 hours in total, spread across a month in amongst other projects. NX offers such a vast range of tools it can be daunting to know where to start. But, by following the NX certification journey you can focus on the essentials, before starting to branch out and investigate further into specialized areas of your interest. Enhancing the long term benefits of its usability for the future of digital engineering are worth it.