Product Manufacturing Information Improves CAD Workflow

Product Manufacturing Information (PMI) lets you focus on what matters to you most: designing better, more innovative products. But what is Product Manufacturing Information?

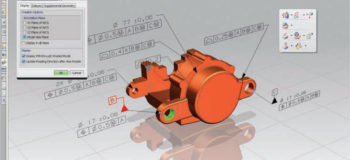

Product Manufacturing Information or PMI embeds info directly into a 3D CAD model about how to manufacture a product, run analysis on or inspect a product. You no longer need 2D drawings to convey information like GD&T (geometric dimensions and tolerances), surface finish, material specs, or 3D annotations.

So what benefit does PMI offer you? Well, you don’t have to make any 2D drawings! Product Manufacturing Information replaces this boring, time-consuming task with a simpler—and faster—way. You can embed any necessary information directly in your 3D model using a few mouse clicks. Best of all, with PMI you only have to document that info once and it will be reused downstream.

Data reuse eliminates communication errors between teams, so you’ll see improvements in quality along with savings in time.

Just how much time can you save? Lifecycle Insights asked more than 300 people who participate directly in the product development supply chain and found that, on average, companies that use PMI embedded 3D models:

- Spend 6.6 fewer hours on engineering documentation per week (that’s 40 full work days per year!)

- Address 2.5 fewer emergency issues per month

- Assess why parts don’t fit together 4.9 fewer times per month

What will you do with all of that time you’ll save? My bet is you’ll be able to get even more creative and innovative with your product designs.

This article is based on Tech-Clarity’s How-To Guide for Implementing PMI: Making Product Manufacturing Information a Strategic Advantage.