Simcenter FLOEFD v 18.0 for NX : What’s New

Good news for the Siemens NX user community: the latest release of Simcenter FLOEFD for NX has just been announced and is available for immediate download. Supporting up to NX 12.0.2.9, Simcenter FLOEFD features a wide range of new thermal management and productivity enhancement related functionalities to support the design engineer interested in using computational fluid dynamics (CFD) inside Siemens NX. Let’s take a close look at them now:

New Battery Compact Models

The new battery compact model calculates the heat dissipation rate based on the electrical or electrical-chemical characteristics of battery cells. The two new models are:

- The Equivalent Circuit model: it represents a cell as a second-order resistor-capacitor (2RC) equivalent circuit model. The model inputs are OCV (open circuit voltage), resistance and capacitance values as functions of SOC and temperature.

- The Electrochemical-thermal coupled model: this model simulates thermal and electrochemical behaviors of the battery cell and requires the chemical properties of electrolyte.

The heat dissipation rate should be applied to the cell in both models. The state of charge, voltage, current and the temperature distribution can also be predicted (requires the Simcenter FLOEFD Power Electrification module).

Increase Accuracy with Calibration

Since semiconductor package characteristics data used in simulation can differ from the reality due to lack of knowledge about the internal structure, you can increase accuracy of your data by using Simcenter T3STER. The market-leading thermal transient measurement system lets you obtain and use the true package internal structure and material properties to drive even more accurate simulation. In addition, the new Calibration mode in the Parametric Study functionality will search for package dimensions and material properties to fit the measured data (requires the Simcenter FLOEFD for NX Automatic Calibration module and Simcenter T3STER hardware test or data obtained from it).

Flux Plot for New Insight

A great tool for getting insight into your design, the Flux plot shows the amount of heat going from one component to another (by conduction). The plot can also show heat transfer to fluid via convection or radiation. In addition, you can group components to see the heat calculated for all grouped components. Lastly, refer to the pie chart to understand the balance of heat for incoming and outgoing heat.

Smart PCB:

A new Smart PCB feature represents a PCB as a Network Assembly with a large number of nodes. The network assembly is constructed from the layer images providing precise conductivity and capacity map of the PCB’s internal structure. The Smart PCB also allows importing effective conductivity map as a *.csv or *.trmexport file (requires the EDA Bridge module).

Improved EDA Support

The disciplines of electrical and mechanical engineering are getting closer and closer so that engineers require greater connection between their Electronic Design Automation (EDA) and Mechanical Design Automation (MDA) tools. With the latest release of Simcenter FLOEFD, the Simcenter EDA Bridge module now supports the IPC2581 (Rev B) and IDX (Prostep) formats.A new method to calculate effective thermal conductivity based on empirical data is also added (requires the EDA Bridge module).

OneSim Co-Simulation

OneSim is a unique tightly coupled co-simulation workflow that enables a Simcenter FLOEFD model to be considered as part of a Simcenter Flomaster network. One or more Simcenter FLOEFD hydrodynamic boundary conditions are nominated for linking to the Simcenter Flomaster network. Once connected, a simulation instigated from within Simcenter Flomaster will solve both the FLOEFD model and the Simcenter Flomaster network concurrently, until steady state or transient convergence. Flow rates, pressures and fluid temperatures will be communicated through the linked boundary conditions / hydraulic nodes throughout the solution process (requires the Simcenter Flomaster v9.1 product).

Radiation Related Functionalities

There are a handful of new functionalities, namely:

- It is now possible to calculate absorption/emission by H2O and CO2 fluids in combustion analysis.

- For a combustion analysis you can now estimate the mass fraction of non-equilibrium Nitric Oxide (NO) based on the Thermal-NO (Zeldovich-NO) mode. The Thermal NO mechanism is a predominant source of NOx in gas flames at temperatures above 1800 K (requires the Simcenter FLOEFD Advanced module).

- Radiation: On-Orbit radiation. For a spacecraft orbiting a celestial body (a planet or a moon), the main sources of environmental heating are direct sunlight, sunlight reflected by the celestial body (albedo), and the infrared (IR) energy emitted by the celestial body itself. Such on-orbit radiation can now be simulated for a given celestial body and orbital characteristics. All planets and the moons are pre-defined in the database (requires the Simcenter FLOEFD Advanced module).

Lighting Related Functionalities:

- Film motion: Consider water film motion on surfaces due to gravity and aerodynamic forces for fogging/defogging analyses (requires the LED or Advanced module).

- Solar radiation direction: you can now visualize the direction of solar radiation at the loaded time moment and in animations.

- Coating surfaces: You can assign a radiative surface with defined emissivity to a surface of a semi-transparent solid to represent a metal coating on semi-transparent media (requires LED module).

- Flux measure on semi-transparent surfaces: you can now quantify incoming radiation flux on semi-transparent surfaces.

- Radiation: Setting Radiation Temperature other than the global Environment Temperature for a specific wall. A new “Wall to environment wall” type of radiative surface allows setting for a particular surface a radiation environment temperature other than the global one defined in the General Settings. This type of condition can be used in case different sides of the model undergo radiation with different environment temperatures.

Enhanced User Experience

- Component Explorer: Allows you to list material and source conditions applied to components in one table. So now you can easily change materials, LEDs, two-resistors as well as edit material properties and heat generation rate values for multiple components quickly.

- Comparing multiple models in Simcenter FLOEFDView: Easily compare results of multiple variations of the same model with the new FLOEFDView (a free Simcenter FLOEFD results viewer). To use this function, the results must be based on the same newly available Scene template and saved in the Simcenter FLOEFDView file format (*.efdscene). When opened in Simcenter FLOEFDView such results can be synchronized for orientation, plot visibility and even pallet’s minimum and maximum values. These Scene files can also be created for multiple projects at once with the batch results processing.

Post-processing:

- Creating cut plots or flow trajectories has been made more streamlined. You can create a cut plot normal to a curve. This new option makes creating a section along the centerline of a tube or circular channel easier. Surface parameters can now be calculated in a section place and not only on the geometry surfaces. Simply select a plane, planar face or curve to calculate local and integral parameters in the section. Also cut plots and surface parameters can be linked to the location of the cut plot. If a section plane divides the model into several closed contours, parameters can be calculated separately for each contour. Flow trajectories can start from linear or rectangular virtual objects (not a CAD geometry) which you can interactively move, rotate and resize in the graphics area.

- The new custom visualization parameter enables the use of logical expressions such as IF, OR, AND etc. as well as larger than and less than. This enables the plot of only specific criteria or the surface area these criteria apply to.

Improved User Productivity:

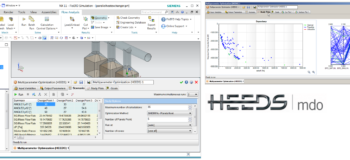

Embedded HEEDS: The latest release of Simcenter FLOEFD offers the option for use of a new powerful design exploration engine in the Parametric Study functionality. You can now access the efficient and robust optimization and search functionality of the SHERPA algorithm from HEEDS™ embedded into Simcenter FLOEFD. The new functionality simultaneously leverages multiple global and local search strategies, and adapts the search as it learns more about the design space. It requires no algorithmic search expertise on the part of the user and incorporates user intuition through its collaborative search capabilities. The process allows you to identify higher-performing families of designs with minimal simulation time and cost (requires the Simcenter FLOEFD for NX Design Intelligent Design Exploration module).

- Improved Geometry variations through Variables (Solid Edge), Expressions (NX), Parameters (Creo) or Equations (Simcenter FLOEFD Standalone) as well as the new Simcenter FLOEFD project parameters which can be used in boundary conditions and parametric studies.

- Improved API to create project from templates and face based (color or name) boundary conditions. The API is available for Visual C++, Visual Basic and Visual Basic for Applications. This can be leveraged to create highly automated workflows.

- Name Templates have been introduced to define the boundary condition name at its creation.

- New feature goals can be created together with the boundary condition and are linked to it. When changing the reference of the boundary condition the goals will be automatically linked to the same reference and if the boundary condition is deleted, the goal is deleted with it.

- The import of Siemens NX materials is available if materials are applied to components in NX and will be automatically defined as boundary conditions and used for the simulation.

For additional information and a complete list of new capabilities, please go to the Support Center site (https://support.mentor.com) or read the release highlights file provided with the installation package.