Using Migration Reports to Gain Insight into the Migration Process

If you have been following the Migration Monday series of posts then you now know that Content Migration Manager is more than just a data conversion tool, it also has powerful capabilities for managing the migration process and validating and reporting on migration results.

In this post we will take a look at the CMM reporting process. As part of the migration process, CMM will generate a migration report for every part, assembly and drawing processed. Since drawing migration reports were covered in some detail in last week’s post, in this post we will focus mainly on migration reports for parts and assemblies and some of the useful information they contain.

Probably the most important pieces of validation information we look for after migration is Part Fidelity and Assembly Fidelity:

- Part Fidelity is used to determine if the final part geometry in NX matches the original part geometry in the SourceCAD system.

- Assembly Fidelity is used to determine if the position of every component in NX matches the original component positions in the SourceCAD system

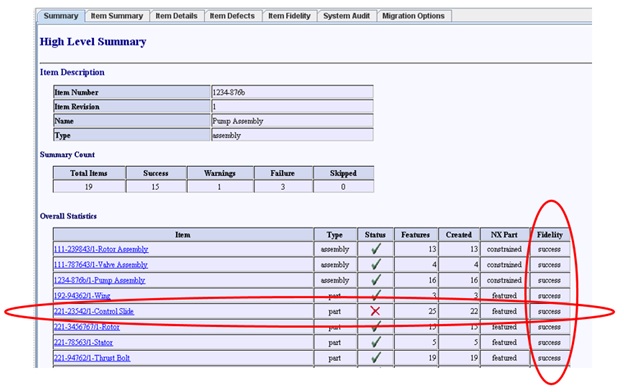

This information can be easily reviewed in the right hand column of the Migration Summary Report:

In this report we can see from the summary that all parts and assemblies are passing the fidelity checks. We can also see that one of the parts (Control Slide) has some feature issues. 25 features existed in the SourceCAD system but only 22 were successfully created in NX.

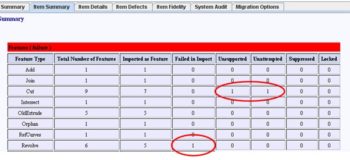

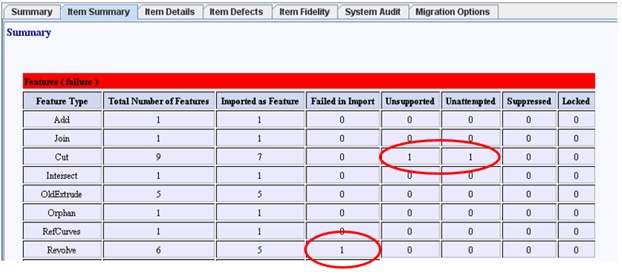

By drilling down into the Item Summary tab for the Control Slide we can get a better understanding of the feature issues:

The feature table shows that 1 Revolve and 2 Cut operations have issues and we can drill down even more by going into the Item Details tab to get a better understanding of why the features were not successfully created in NX.

Since the Control Slide is passing the Part Fidelity check, there is nothing required to be done with the part at this time. If the part is revised in the future, then you can decide if you would like to repair the 3 feature issues or use NX Synchronous Modeling tools to make the change.

In this article you can get an overview of the feature repair process in NX.

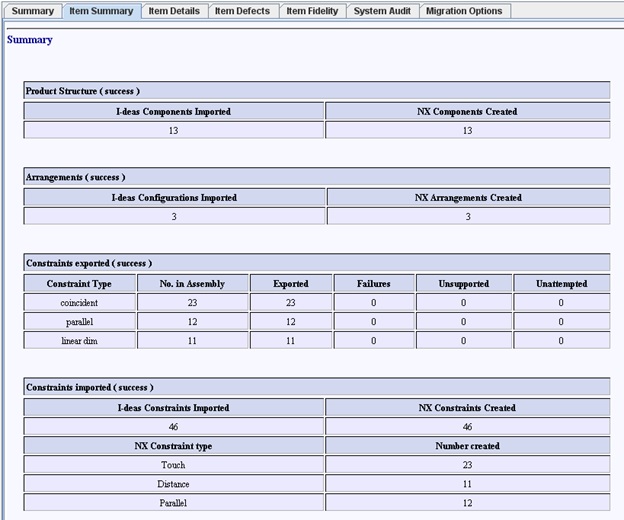

We can also drill down into the assembly reports to get a better understanding of the migration status of assembly constraints, arrangements, etc:

In summary, as with drawing migration reports covered in last week’s post, without ever viewing the parts or assemblies you can use the migration report information to establish whether or not the migrated parts and assemblies are passing your baseline criteria for a successful migration.