Video Case Study: Nissan Qashqai

“I want it, and I want it now!”

You may have heard these words come out of your child’s mouth at one point or another, or perhaps your inner child has stamped its foot while snarling this phrase. Whatever the case may be, the fact remains that we live in a culture of now.

The ever increasing speed at which technology improves and changes has conditioned society to want new and improved products sooner. While we may not always express our wants in such a straightforward and demanding way, the expectation is there.

“The development lifecycle at Nissan is being shortened all the time,” Nissan senior engineer Ian Keen says.

This phenomenon is not unique to Nissan. So what does this mean for you as a design engineer? You face pressure to not only deliver products faster, but you’re also expected to be better at what you do.

Nissan decided the solution was to improve their process by improving their PLM solution, according to vice president of Nissan vehicle design and development in Europe, David Moss.

“NX offered us a lot of advantages from both the quality and timing perspectives,” says David.

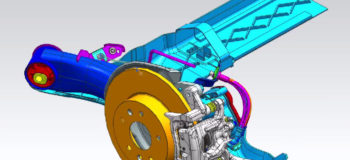

Nissan engineers saw the immediate benefit to their work as well. With NX CAD they were able to take styling data from their studio in Paddington to develop the new Qashqai, reducing data creation time by 20%.

Nissan also used Teamcenter to collaborate and work in real time with team members from around the world.

Watch the entire case study video here to learn more on the new Nissan Qashqai made possible with Siemens’ NX CAD and Teamcenter.