Best practice: control cabinet engineering Digital Twin

Siemens Plant for Combined Technology engineered Robot Control Cabinets (RCC) with Smart Data and NX Electrical Design

The digitalization of industrial value chains is gaining momentum: this is the only way to produce individual products at series costs with the shortest delivery times at the same time. A good example is provided by mechanical and plant engineering with its suppliers, for example for hardware engineering and the assembly of electrical equipment.

The system complexity of the ‘trades’ control cabinet design and manufacturing usually arises less from their technical functionality. This is due to the enormous variance of customer specifications in terms of user standards, specifications of the components to be used and the execution details.

These requirements essentially determine the cost of electrical equipment. This makes modular concepts, manufacturer-validated – largely automated – technical data, as well as digital engineering processes that are passed through in the shortest possible time. This allows the individual specifications to be reconciled with cost and deadline pressure.

A and a thing less, the Siemens Industry Mall provides manufacturer-validated, high-quality technical product data. The CAx-download-manager of Siemens Industry Online Support is available for data exchange with electrical engineering tools. All components of the Siemens Industry Mall are available to the electrical engineer in NX Industrial Electrical Design via this tool. The Siemens plant in Chemnitz (WKC) proves that this interaction works seamlessly with the ready-to-connect, pre-configured solution for robotics projects – Robot Control Cabinet. Seamless because NX Industrial Electrical Design generically combines 3D design with electrical design.

Intelligent product data for electrical engineering

The Siemens Industry Mall is the platform on which the entire product portfolio of Siemens Control Panel is accessible: From the selection of products to the order and delivery tracking, the Industry Mall enables complete purchasing processing – directly and regardless of time and location. Through this portal, the electrical engineer can directly choose from a total of 135,000 products of automation and drive technology. The electrical engineer has appropriate search and filter functionalities to select the appropriate product for his task. On the platform, all technical information of the selected product for electrical engineering is then available to him. The primary premise is to simplify and speed up the engineering process.

Robot Control Cabinet RCC – the engineering workflow

The Chemnitz (WKC) combination technology plant, which is part of Siemens’ digital industry, has been developing and manufacturing electrical equipment and electronic assemblies for mechanical and plant engineering for more than 60 years. The range of services ranges from order assembly according to customer documents to system partnership. For several years, WKC has relied on the digital exchange of information with customers and suppliers as well as in internal processes. Manufacturing Engineering, which is upstream of production, transforms all customer-specific information and technical rules into a so-called “Digital Twin” (DT).

This is then available to the respective production areas. These include, for example, material logistics, mechanical prefabrication (cutouts, drillings), line assembly as well as electrical assembly, wiring and testing. This procedure enables the realization of individual customer projects with short turnaround times with high quality and cost efficiency. Plant manufacturers have the choice between an immediately available and ready-to-connect control cabinet basic variant for their robotic systems, a pre-designed solution with additional options or a completely customer-specific application.

Robot Control Cabinets from Siemens-WKC

In the course of increasingly networked systems in production, machine and plant manufacturers are faced with the challenge of equipping their machining machines with handling and transport tasks. Following these requirements, a software and hardware-scalable application for robotics applications based on CNC control was developed. Thus, a system or technology change to a robot controller is not necessary.

The RCC is a standardized ready-to-connect switchgear solution for 6 axis robotic systems controlled with the integrated solution “SINUMERIK Run MyRobot”. Kinematic systems with a payload of up to 650 kg are supported. Examples of applications can be found in machining (measurement, polishing, deburring) as well as in plant engineering (rivets, coatings, additive manufacturing). The RCC consists of a standardized basic version that can be extended with options. Completely customer-specific expressions are also possible. The pre-configured basic version can be used just-in-time for quick and easy commissioning.

In addition to the hardware and software design for the application, a digital twin of the electrical equipment is also available. With eCl@ss-based component data, it can be integrated into specific design and design systems such as NX Electrical Design. The module idea and the reuse of assured knowledge guarantee an electrical equipment of the highest quality.

NX Industrial Electrical Design integrates Siemens Control Panel product data

The Robot Control Cabinet RCC includes many Siemens Control Panel products. These are divided into the following product portfolio areas:

- Protection and switching devices

- Power supply

- Motor starter and frequency converter

- Controller

NX Industrial Electrical Design manages the data from the product catalogues (Siemens Industry Mall) within the NX Reuse Library. From here, the intelligent data can be used for the creation of the electrical schematic and the control cabinet layout. This library can be filled via the Siemens Industry Mall or the CAx-Download-Manager, which is integrated directly into the NX Industrial Electrical Design user interface. The holistic Siemens “Integrated Control Panels” approach ensures high quality and consistent data quality across all product portfolios.

Mechatronic data model ensures engineering consistency

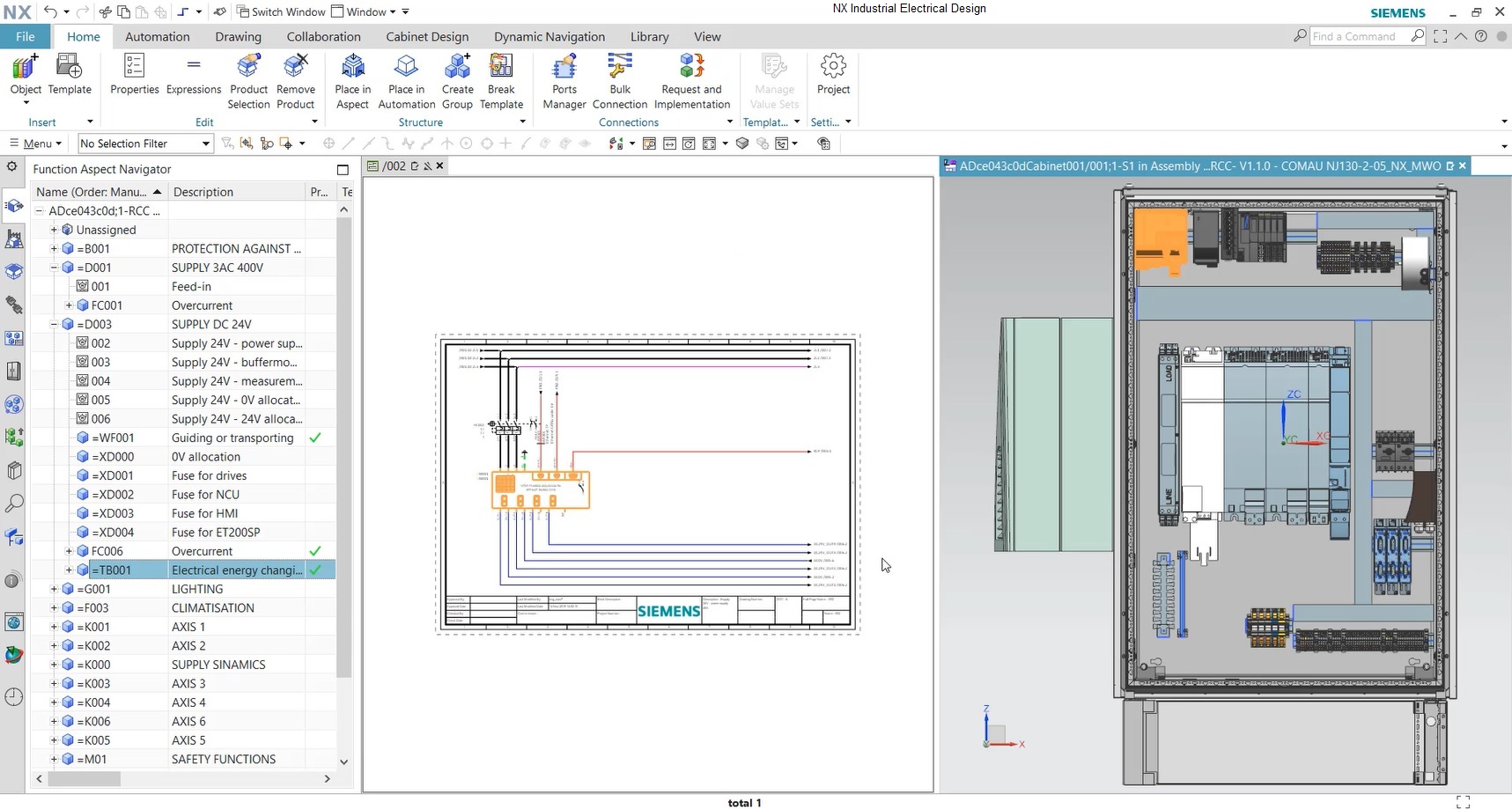

NX Industrial Electrical Design from Siemens Digital Industries Software enables simultaneous, parallel engineering across all disciplines involved. The basis for this mechatronic engineering approach is a common data model for mechanical, electrical and automation engineering. This results in consistent data between system planning, mechanical CAD, circuit diagrams, PLC hardware configuration, signals and PLC software.

The mechatronic data model included in NX Industrial Electrical Design ensures consistency throughout the entire engineering process. As a result, the solution acts as a mechatronic control center and now offers NX Industrial Electrical Design, a fully integrated, full-fledged ECAD module whose data is synchronized with mechanical and automation engineering.

Integrated in NX, Industrial Electrical Design includes extensive functionality for the creation of circuit diagrams and 3D cabinet design. This data model links the 2D schematic symbols and the corresponding representation in the 3D cabinet. Thus, the electrical engineer has consistent data at all times and the possibility to navigate between the circuit diagram and the control cabinet display.