Shikun Enterprise uses NX CAM and Solid Edge to reduce machining time by 70 percent

Solid Edge and NX CAM software solutions help Shikun Enterprise streamline complex manufacturing processes and increase productivity.

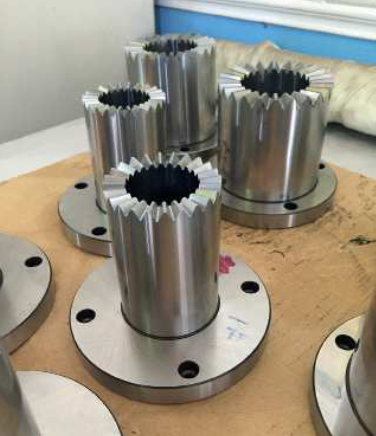

Based in Dashe, Kaohsiung City, Taiwan, Shikun Enterprise develops and manufactures machine parts and was the first company in the area to have a computerized numerical control (CNC) machining factory, which is well known for its capability to machine custom parts.

In 2015, Shikun took a step that may have seemed rather bold to industry competitors at the time. The company replaced all of its computer-aided design/computer-aided manufacturing percent(CAD/CAM) software with the high-end 5-axis compound machine tool from Mazak (Japan). Zeng Zhenxiong, the founder of Shikun Enterprise, and his two sons worked together to upgrade the company’s technology from 3-axis machining, which was used throughout the industry, to the expensive 5-axis machining, which few people had dared to try.

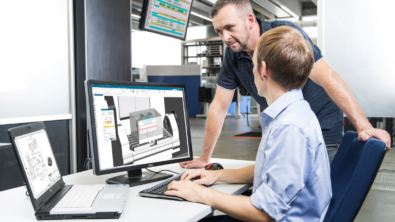

Fortunately, Shikun found Siemens Digital Industries Software partner CADEX Technology and worked together to come up with an efficient software upgrade solution: Use Solid Edge software for design and NX CAM software for machining in hopes of addressing use issues by integrating CAD and CAM from the same supplier.

Thanks to CADEX Technology’s well-thought-out course planning, we were able to learn how to use and integrate Solid Edge and NX CAM in a short time. In addition, when we have any practical problems, their technical consultants are there to offer us professional guidance and help us find a solution to the problems.

Zeng Lvjin, Head of Machining Business, Shikun Enterprise

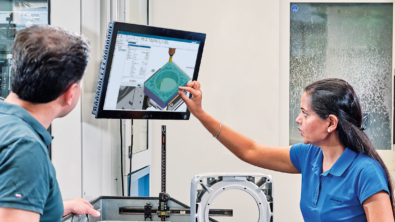

Furthermore, Shikun uses NX CAM to generate the complete machining process using comprehensive NC programming capabilities to drive milling, lathes and 5-axis machines. Using the precise digital twin of the machines, fixtures and workpiece, the company can simulate and optimize machining processes. This eliminates errors in production and increases machine uptime, which can drastically reduce cycle time. Shikun estimates the machining time has been reduced by about 70 percent, which means faster delivery rates and lower order production costs, thereby attaining the goal of improving profitability.

Comparing the results before and after adopting the new solution from Siemens, NX CAM has indeed helped Shikun substantially improve its machining quality. For milling and turning, the double precision feature in the software facilitates optimal surface machining, while the synchronized layout of point groups improves surface precision, thus helping Shikun increase its capabilities for machining high-precision, large-size differential gears. Such features take advantage of the technical value of advance tool path methods, enabling Shikun to easily tackle the most sophisticated challenges from customers.

NX CAM and Solid Edge have built-in integrated operability, enabling quick design changes without wasting time to reset the machining programs. On top of that, the seamless data migration capability in NX CAM enables synchronized data update.

Zeng Lvjin, Head of Machining Business, Shikun Enterprise

Read the complete success story today!