Blog series: The Value of NX for Part Manufacturers – Leveraging robotics programming technology

At Siemens PLM software we can provide a wide range of manufacturing engineering software solutions. We have a leading position in robotic programming developed and proven over many years, in fact as a mainstay of the Tecnomatix software suite. The focus of this technology has arguably been in the area of assembly manufacturing, with automotive production being a major use case. In part manufacturing we have enjoyed an unparalleled run of success with NX CAM software aimed obviously at programing a wide range of machine tools.

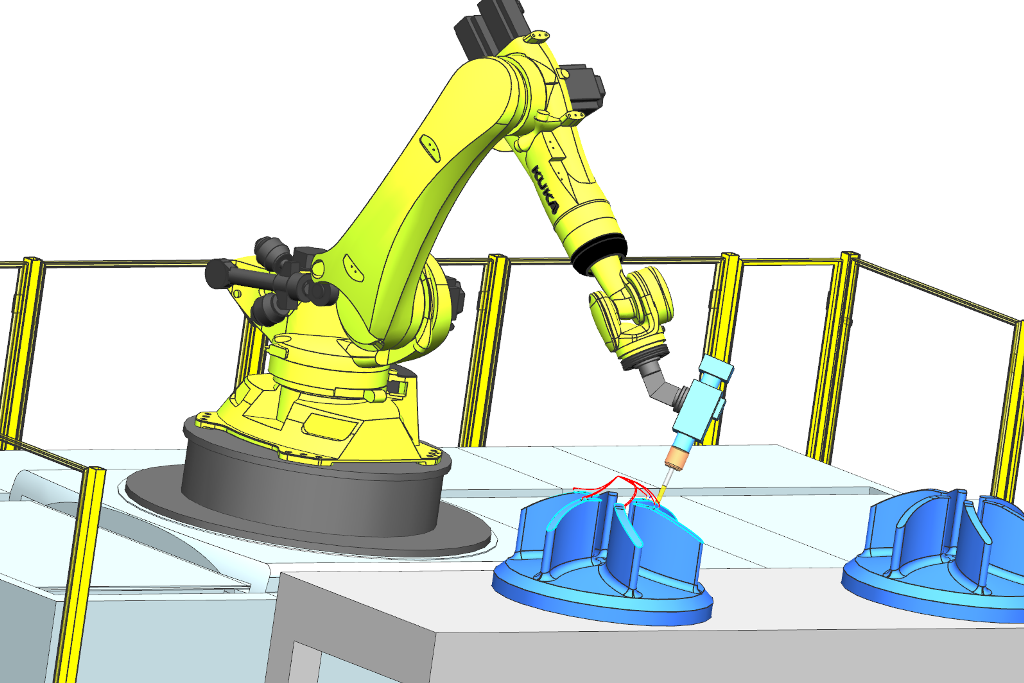

Recently we built key elements of our robotics programming technology into NX CAM. Now our part manufacturing customers can use the same NX environment that he or she is familiar with to program a robot. The method is similar to machine tool programming, the post processing and simulation tools are the same and once again we can say that it is all in NX. The big step is to enable the CAM system to handle more than the 5 axes that most machines tools go up to. Robots and the associated part holding systems or robot transport systems can have many axes to control, often simultaneously. You can learn more in this fact sheet, “NX CAM Robotics Programming.”

The use cases for the ability to program a robot for part manufacturing are many and varied. The initial projects were driven by post machining operations such as polishing, linishing or deburring. A common requirement is the need for the tool to follow precise path relative to the part geometry. Obviously this is standard in a CAM system. These secondary operations can be extended to other functions such as painting spraying for components. This would typically require additional capability to manage the specifics of paint spraying. Here again Siemens PLM can take advantage of proven capability in robotic programming developed within the Tecnomatix product line and use this within NX for the part manufacturer.

Robots can be used for light milling and drilling machining operations. In fact we can see that adaptive technology may soon make it common to see heavier forms of machining being successfully undertaken using specially equipped robots.

In another blog, “The Emergence of Multi-Axis 3D Printing Solutions,” I speak to the dramatic rise in interest in using robots for multiple forms of 3D printing. Once again we see the reach of NX being extended into these areas to offer an “all in NX” solution.

There are many more reasons why NX is a platform of choice for so many part manufacturers. I will provide some further examples for the next time you visit the “NX for Manufacturing” community site. You can read my previous blog in the series, “Value of NX for part manufacturers.”

Let us know what you think of our blog series in the Comment section below.

NX CAM Robotics Programming

NX CAM Robotics Programming

![Siemens leads collaboration for advanced EV component manufacturing [article]](https://blogs.stage.sw.siemens.com/wp-content/uploads/sites/15/2024/03/erod-_SME-395x222.png)