The future of manufacturing on display at WESTEC 2023 [VIDEO]

What do you look for in a manufacturing trade show? When I go to one of these events, I look forward to seeing the latest in manufacturing technology and how it can make a difference for businesses. It’s always exciting to see how these innovations can level up the game for manufacturers. This is what I was hoping to see when I attended WESTEC AeroDef 2023, the leading California manufacturing technology trade show from November 7-9, 2023.

It was a beautiful, sunny day when I arrived at the Long Beach convention center. I eagerly picked up my badge and headed into the exhibit hall along with the many other attendees from various industries such as aerospace, medical, industrial machinery, and automotive. Inside the exhibit, the future looked as bright as the weather outside: 364 exhibitors demonstrated their latest offerings of CNC machines, CMMs, robotics, and more. However, while these technologies were impressive, most of them were lacking connectivity between them. And that’s what modern manufacturers need to stay competitive – a seamless manufacturing process chain, from the digital 3D model to precision components.

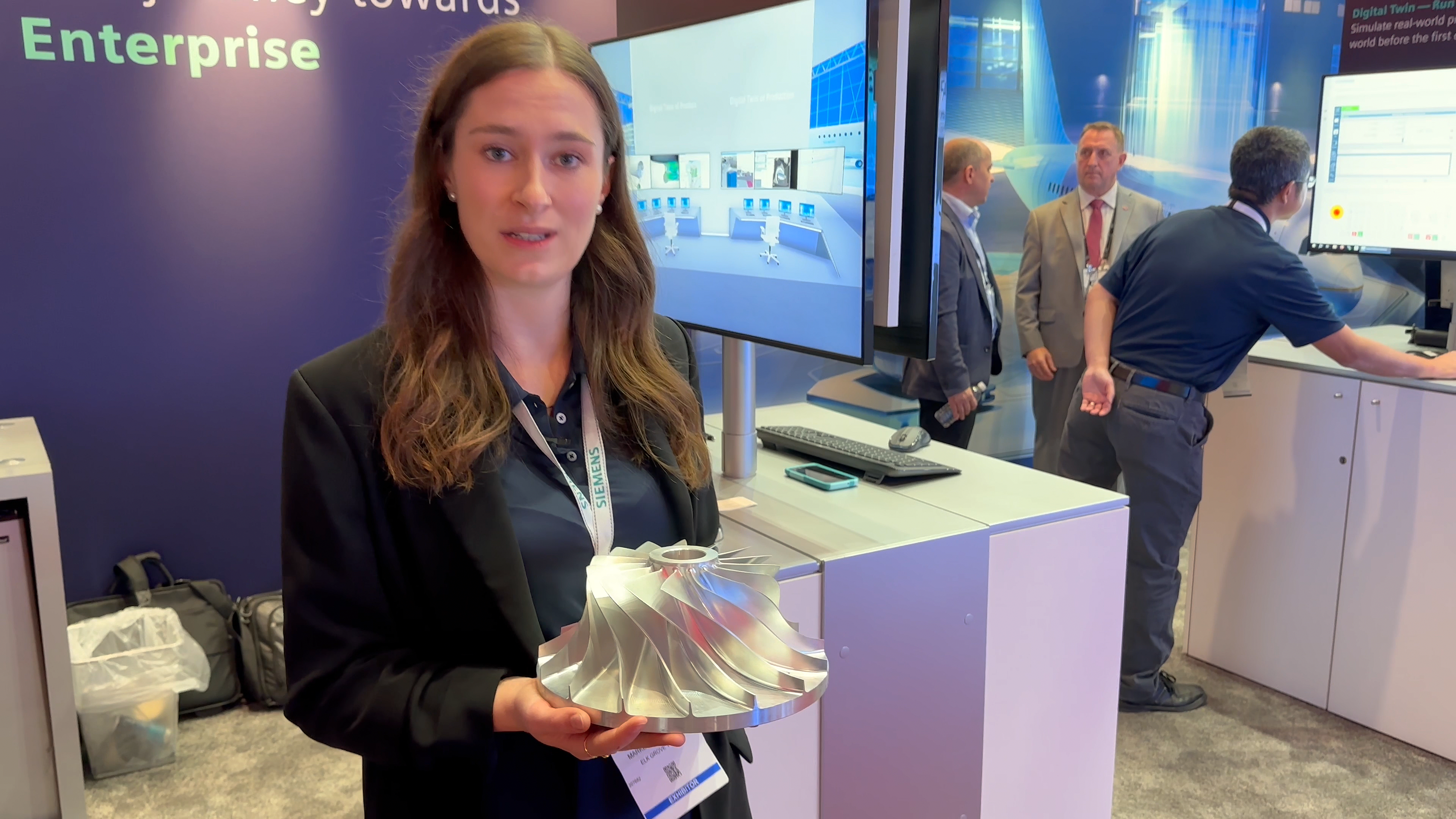

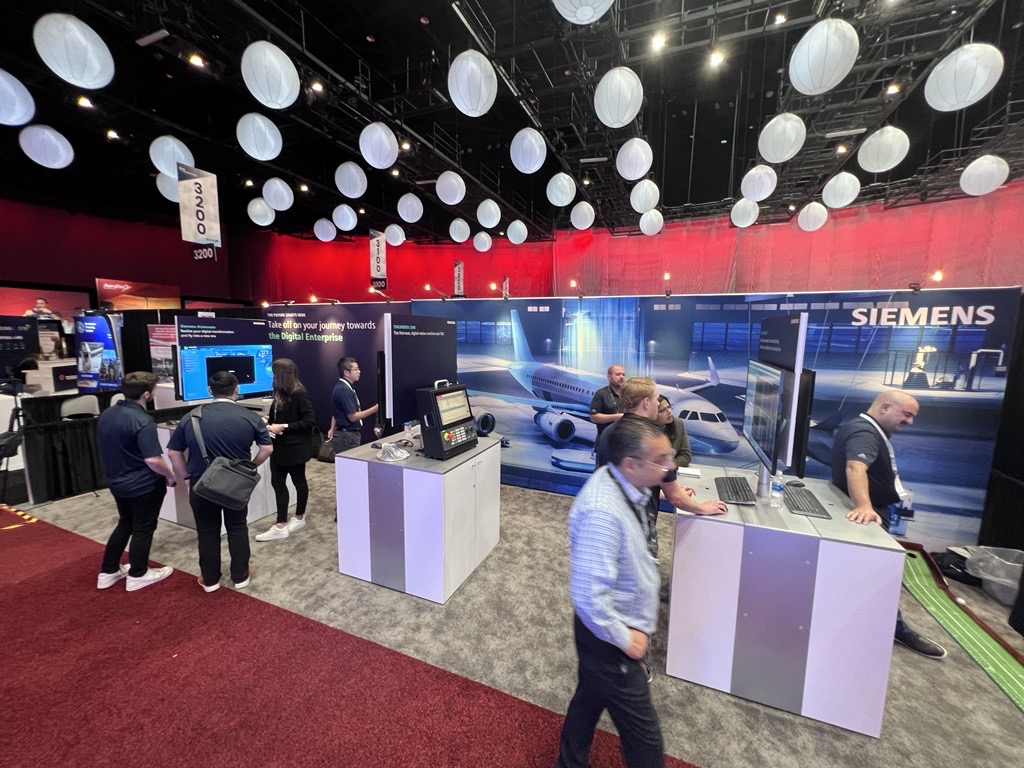

The star of the show? The Siemens solutions showcase. It stood out to me for its focus on innovation as well as support of the entire manufacturing process. As the banner on the booth reads, “the future starts here!”

Taking an aerospace part as an example, an impeller, the booth takes you on a tour covering each step of the end-to-end process of manufacturing such a part. It begins with the design of the part where the digital twin of the product is created. That digital twin is then checked against any potential physical changes such as temperature or force. Once those have been evaluated, you can link it with a digital twin of the CNC controller and generate the toolpaths for the chosen manufacturing process which in this case is milling.

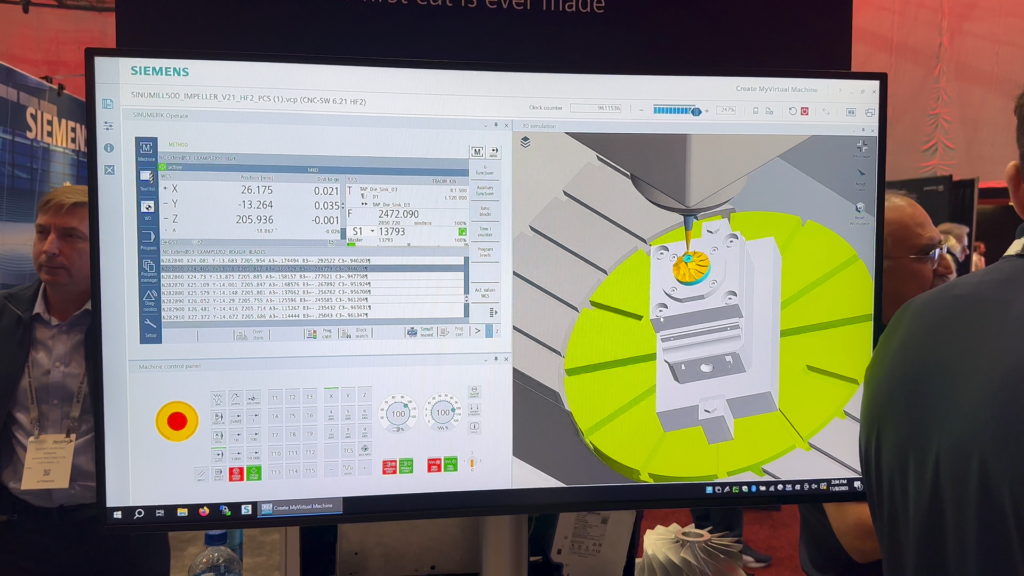

For this, you can use NX CAM’s turbomachinery milling feature which helps you simplify the programming of complex parts like this with advanced 5-axis NC programming operations. It can automatically generate the milling toolpaths and optimize them by precisely controlling cut patterns, toolpath smoothing and tool axis stabilization for the edges. By doing all of this digitally first, you can make certain that everything works before going into production, thereby ensuring error-free machining, and saving valuable machining time. You can then also simulate and validate each step of the production to ensure the part is produced faster and more sustainably.

Once the data is prepared, it is then sent to the shop floor where you can use the Sinumerik One to control your CNC machine and mill the part. Using RunMy Robot with the Sinumerik One, you can also seamlessly and quickly integrate a robot without the need for any robot programming knowledge. Once the part has been produced, the Machinum portfolio is used to to ensure optimal workpiece quality and productivity. You can also use predictive maintenance to increase production uptime. All of this can be achieved with the Siemens Xcelerator portfolio.

Watch the video to see an overview of the digital enterprise solutions showcased at the booth: