IPC APEX Electronics Show 2017: Siemens’ booth demos impress visitors

Written by Maria Mosto, Siemens PLM Software

IPC APEX Expo is a five-day event like no other in the printed circuit board and electronics manufacturing industry. Professionals from around the world came together to participate in the technical conference, exhibition, and professional development, standards development and certification programs at the February 2017 event. This year over 300 people visited the Siemens booth and learned how Siemens can help them realize the potential to change the way they manufacture products.

We demonstrated how Siemens connects the digital thread from planning and design to production and beyond, creating an integrated manufacturing data model with the intelligence to easily interoperate among departments, systems and sites helping close the loop for improved efficiency for the electronics industry.

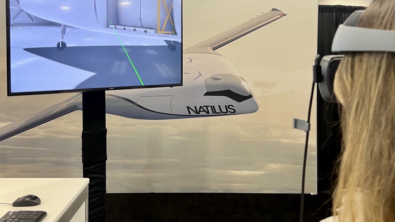

The booth featured a live demonstration with a Universal Robot performing previously impossible electronics assembly operations. Siemens and ArtiMinds Robotics, a Frontier Partner Program member, have integrated the ArtiMinds Robot Programming Suite (RPS) into the Siemens Process Simulate framework to enable a new level of flexible robot use in production.

Four posters were also submitted to the conference with abstracts and each provided the audience with a very visual way to understand exciting new technologies and the strategies to implement them.

Check them out and let us know what you think in the comments section below.You can also download the posters from the attachments section.

Additive Manufacturing Reshapes Everything. New software, hardware and material technologies transform the way products are designed and manufactured. 3D printing helps companies produce new-generation parts that were impossible to make before. Learn about revolutionary technologies that industrialize 3D printing.

Advanced Robotics for Complex Electronics Assembly. In electronics assembly today next generation products are adding manufacturing complexity and increased production costs are driving the need for automation. However, automation is reducing errors while increasing quality and speed, and flexible, adaptable robotics technology is readily available.Learn how you can easily automate difficult tasks for improved performance.

Green Design and the Benefits of PLM. Consumers demand greener, more environmentally and socially compliant products to protect the earth and mankind. Adopting strategies to enable the efficient design of green products can help manufacturers meet consumer and customer demands, comply with regulations and create winning products.Learn about the challenges, methods, results and our conclusions about Green Design.

Product Performance Intelligence for Better Products and Customer Experience. Prevent recalls, improve quality, and deliver better customer experience. Challenges are growing for electronics companies. Valuable opportunities exist in these challenges. Disparate data silos inhibit opportunities. Learn how you can transform data into product performance intelligence and seize the opportunities and deliver proven business value.