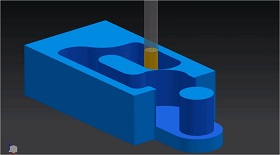

NX for manufacturing: Enhanced mold and die machining in NX CAM 12.0.2

NX CAM 12.0.2 is available now! In this video you will learn about enhanced mold and die machining in the latest version of our software.

Hello! I’m Alexander Freund. I serve as the lead product manager for mold and die. I am going to talk to you about some of our newest additions to NX CAM.

Adaptive milling is our high speed machining strategy that we introduced in the previous version. The new, innovative pillar cutting feature for adaptive milling will increase tool life and process safety by milling with a helical motion in face milling regions. It addresses a common issue which occurs in high speed tool paths.Doing face milling with a molt spiral can lead to small pillar. Especially in hardened or very tough materials, it might appear that this pillar starts to bend instead of being cut. Therefore, there is a high possibility that it is getting work-hardened. If you are using the cut with helical motion option, adaptive milling will automatically detect when the pillar is being left. It will leave the cylinder and cut the cylinder with a helical cut.

We introduced a new feature with a minimum curvature radius. This will give our customers the capability to influence how adaptive milling is working in corners. For harder materials, it is very useful to use a bigger curvature radius to reduce tool wear and to save machining time. The custom feeds and speeds allow you to fully utilize the newest generation cutters by using the larger ramp angle while doing helical engage motion. Depending upon the part geometry this feature can give you an advantage of up to 20 percent faster machining time.

For finishing, the NX CAM guiding curves gives the user the capability to create a morph tool path between two curves, an offset tool path of one curve, or a racetrack tool path around a guide. The benefit of this tool path is that it is highly controller by the user. He can drive the pattern to follow his intent. Guiding curves works on the part without projection, supports multiple surfaces without the need to define drive geometry. Fast creation of quality tool paths for surface finishing as well as quick repair work are the key attributes of guiding curves.

We are introducing the spiral cut pattern for area mill non-steep. This tool path is designed to produce excellent surface quality on simple part geometry without visible step-over moves on the mill surfaces. The helical cut pattern for area mill gives users the possibility to create a tool path on steep part geometries with a reduced amount of non-cutting moves and a consistent surface quality.

With these enhancements for three axis milling the creation of tool paths is simplified, machining time will be reduced, and the surface quality of parts will be better.

To learn more about the new features in NX CAM 12.0.2, watch our demonstration videos in ‘What’s new in NX 12.0.2 for manufacturing”