Pencil Milling Part 1

“Pencil Milling” is the name given to a machining strategy where a small-diameter ball end mill is used to perform finish milling in small nooks and crannies of a complex mold or die. The word “pencil” is appropriate because the tool size is close to the diameter and length of a pencil. Pencil Milling is a finishing version of rest machining. In NX CAM and CAM Express, we call our pencil milling option “Flow Cut”.

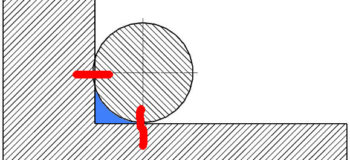

The simplest machining strategy once the bi-tangencies are discovered is to simply run a ball-end cutting tool (of the correct radius size) through that area. We call that the “single pass” method. However, this strategy might break the tool because it is the size of a pencil. Remember our lesson on leverage? So we have an additional strategy for multiple passes.

Multiple Passes is self-explanatory. Instead of a single pass down the middle of the bi-tangency, several passes are generated, each at an offset from the middle. The part I really like about multiple passes is the option to machine steep geometry differently from non-steep. Yes, just like in my last post, I can use z-Level method for steep, and a different strategy for non-steep. Best of all, I can do it all within one operation.

This video will help to show the different cutting strategies.

My next post will discuss some of the Flow Cut options in more detail.

![Siemens leads collaboration for advanced EV component manufacturing [article]](https://blogs.stage.sw.siemens.com/wp-content/uploads/sites/15/2024/03/erod-_SME-395x222.png)