Realize LIVE: Industrial Production of Big Metal Additive Structures

Join us on Wednesday, June 24, 2:10 PM – 2:30 PM EDT / 11:10 AM – 11:30 AM PDT

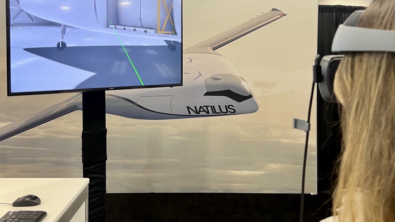

The power of large-scale industrial hybrid metal additive manufacturing is the rapid production of design candidates for practical evaluation in real world environments. Generative and optimized designs are powerful capabilities to create efficient structures that express a new level of performance. Optimized designs are often 3D printed at small scale, however large-scale hybrid metal additive manufacturing provides opportunity to produce these designs for industrial applications such as automotive chassis, aerospace prototypes and even Naval vessels. The Big Metal Additive process has been developed specifically to produce these types of large complex optimized structures. NX Hybrid Additive CAM is used to program additive and subtractive operations to produce these complex geometries.

This session will present a case study of benefits, applied generative optimization, and design rules for producing large scale hybrid metal additive manufactured optimized structures applicable in many industries. The value of full process simulation and visualization will be illustrated. The process of creating multi-axis hybrid additive CAM codes will be explained. Several optimized and produced parts will illustrate the case study.

Speaker: Slade Gardner, President, Big Metal Additive, llc

Dr. Slade Gardner is founder of Big Metal Additive, a company focused on industrialization of large-scale hybrid metal additive manufacturing. Previously, Slade was a distinguished Fellow at Lockheed Martin Space Systems and a Fellow at Lockheed Martin Aeronautics. Big Metal Additive uses multi-axis CAM to produce metal parts with deposition and machining currently on a 6ft x 12ft work table. Recent articles include aerospace components, spacecraft development articles, automotive chassis and an ocean capable transport vehicle.

The adoption of large metal additive manufacturing by the space industry was first accomplished by Dr. Gardner’s industry-leading work with titanium satellite propellant tanks. The industry adopted capability for large polymer extrusion based additive manufacturing systems is attributed to his work beginning in the 2000s when he pioneered the method. The complexity of system-level robotic additive clusters was also pioneered by his work combining additive methods with robotic machining, process monitoring, inspection, post processing and auxiliary assembly operations.

Dr. Gardner has advised corporations, institutes, national laboratories and the U.S. government on strategy and development priorities for adoption and industrial application of advanced manufacturing. His PhD is from Virginia Tech and his BS in chemical engineering is from Lafayette College. Personal interests include traveling and dining with his wife, all seasons of mountain sports and he is an avid motorcycle enthusiast.