Products

The Digital Demo to Machining Better Parts

In a previous blog, we highlighted a recent article by Modern Machine Shop focused on how digital manufacturing powered by NX CAM allows you to standardize processes, shorten lead time, and improve part quality.

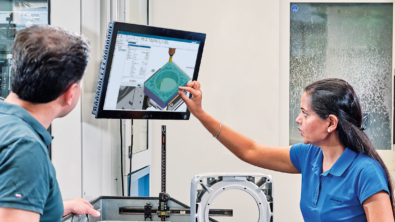

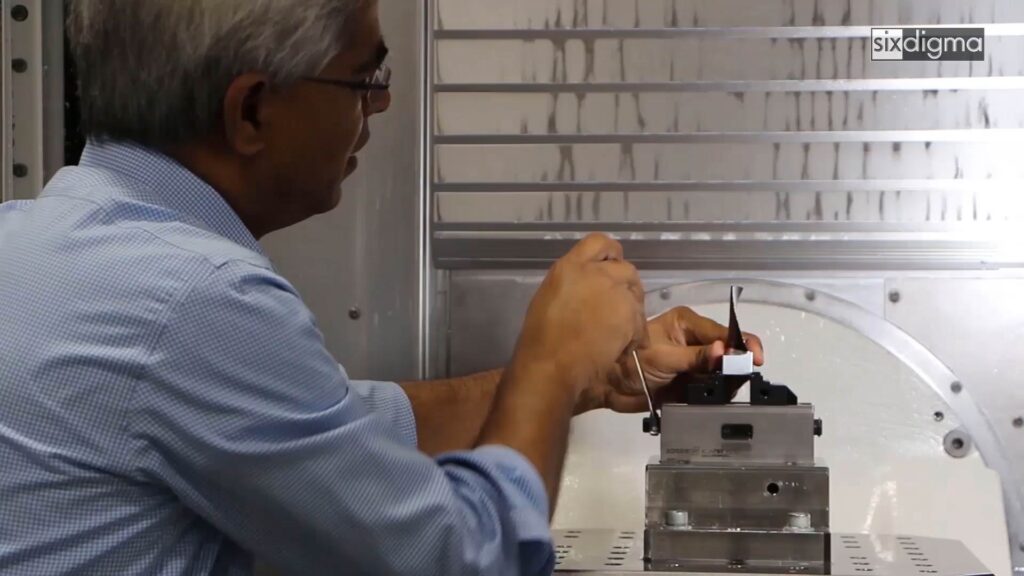

In addition to the article, SIXDIGMA Founder, Edwin Gasparraj, hosts a video demonstration on how the Cincinnati-based company uses digital manufacturing technologies and NX CAM to machine complex airfoils.

The digital demo explains how to:

- Improve surface finish thanks to advanced toolpath technologies in NX CAM.

- Probe complex parts using 5-axis methods to accurately locate the part without special fixturing.

- Validated workpiece surfaces and automatically modify individual toolpaths to machine to high tolerances with closed-loop adaptive machining.

All of these capabilities were demonstrated with the airfoil machined on a Grob 350 5-axis Universal machining center with a Siemens 840D control. Probing was executed with a BLUM DIGILOG touch probe, and all part programming was done with Siemens NX CAM software.