The digital-to-real manufacturing demonstration at IMTS 2022

The official countdown to IMTS 2022 begins! Join Siemens at North America’s largest manufacturing technology show on September 12-17th in Chicago. Visitors will experience the complete production process for an electric vehicle (EV) component displayed at booth #133346 – from design and topology optimization to additive manufacturing, CAM programming, CNC automation, and machining.

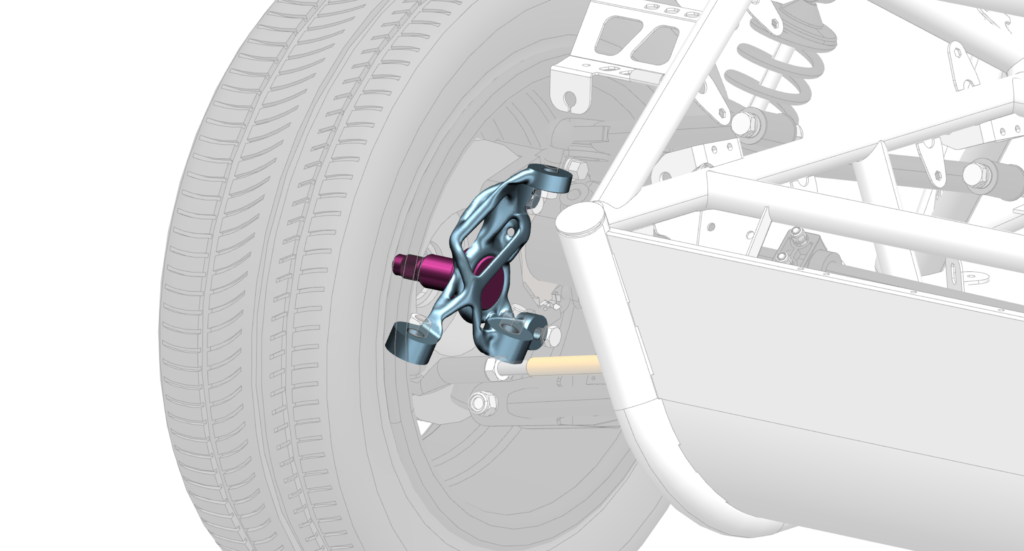

In the digital-to-real manufacturing demonstration, Siemens’ Xcelerator Portfolio, including the NX for Manufacturing solution, reveals a 45% weight reduction for a lightweight, next generation EV component. Attendees witness how the eRod component is produced using a combination of additive and subtractive manufacturing then finished to achieve the necessary dimensional accuracy and tolerance while reducing the programming time by 60% through automation of routine tasks.

From design to post-print validation, learn how digital twin technology boosts productivity, making manufacturers, like you, more competitive and efficient. During the design phase, the part concept is fully validated using the latest topology optimization technologies. Optimization is performed to not only ensure that its performance requirements are met, but also optimized for the next manufacturing phase. Working with the integrated NX for Manufacturing solution, including NX CAD, NX CAM and CMM, users can seamlessly connect the additive and subtractive manufacturing steps, making the process associative and flexible. This enables the use of a single system to program the most challenging 3D models such as the organic shape and light weighted eRod wheel knuckle.

For the final machining phase, programmed with NX CAM, discover key capabilities such as post-processing, featured-based machining and simulation. These advanced features help manufacturers automate programming by applying their own standard CNC programming, inspection path methods, tools, and program templates to ensure that correct revisions of parts are programmed and measured on the shop floor, creating a single source of data through the entire digital manufacturing process. The accurate simulation of the machining process prevents any potential interferences in production, resulting in high quality toolpaths.

Once the final machining phase is completed, we now digitally transform the part production by inputting the verified NC programs directly into the IoT-enabled SINUMERIK ONE CNC to be finished in a two-step machining process. To ensure the workpiece has the perfect surface finish, the part program is monitored by machine tool digitalization software, Analyze MyWorkpiece /Toolpath, where it searches for any possible defects and guarantees the overall part quality of the finished product. The final production will be assembly with a more traditional axle component designed in NX, turned on a Track TC820 controlled by Sinumerik ShopTurn. Using cloud-connected, modular software and advanced manufacturing hardware – the digital thread is woven through the entire process resulting in improved performance, manufacturability and cost.

Discover how manufacturers like you can boost productivity with digital twin technology and gain industry-leading best practices from Siemens’ one-of-a-kind booth experience at IMTS 2022. The journey toward a full digital twin is now complete and we are excited to show you how that can be leveraged using Siemens Xcelerator portfolio of cloud-connected software and IoT-enabled hardware to accelerate your digital manufacturing transformation.