Video Interview with Automation World: The Closed-Loop Digital Environment at IMTS 2022

Attending IMTS 2022 was bigger and better than ever before with almost 90,000 registrants to the show, many of which stopped by our booth. We were eager to reconnect with attendees in person again for the first time in four years! From engaging in-booth demonstrations, C-Suite interviews, and energizing networking events, it was jam-packed with experiential industry chats with our interconnected software and hardware on display. Throughout the week-long show, we also welcomed a variety of industry-leading manufacturing journalists, editors and analysts who wanted to learn more about the process featured in our booth.

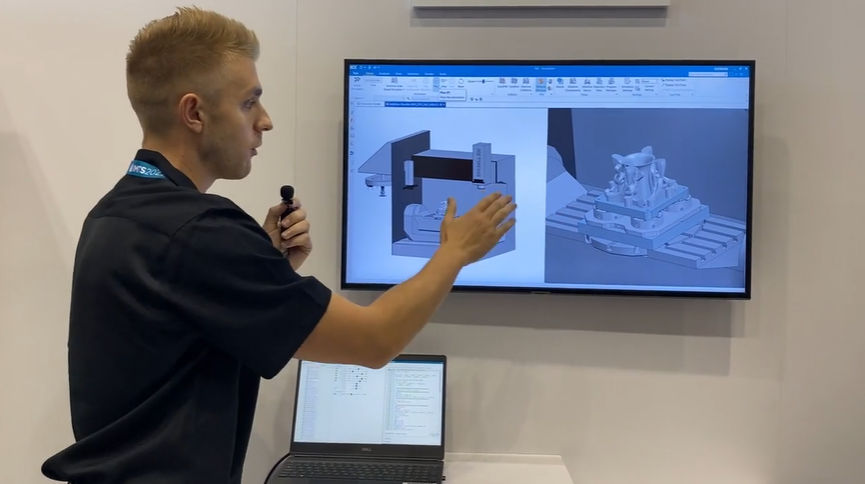

As part of our digital-to-real demonstration, we hosted one-on-one booth tours to showcase how we designed, tested, and created a lightweight component for an electric vehicle displayed at our exhibit. From incorporating NX CAD, NX AM, NX CAM, and CMM inspection programming with Teamcenter Manufacturing, we demonstrated how manufacturers can seamlessly connect the additive and subtractive manufacturing steps with the use of a single software system to program complex 3D models such as the topology optimized eRod wheel knuckle.

Nationally ranked reporters stopped by our booth including David Greenfield, Industrial technology journalist and editor-in-chief of Automation World, award-winning publication which covers the latest developments in the automation field. In his recent article, Greenfield interviewed our very own Siemens manufacturing experts, including Rahul Garg, VP, Industrial Machinery and SMB Program, and Carson Huber, Advanced Application Engineer.

Watch Greenfield’s video interview as he transitions from each stage of the optimized production process for the EV component. Starting with the 3D scanning of the original part all the way to the digitally enabled machining process, his video interview captures how our design and manufacturing software operate in one closed-loop digital environment.

To really optimize the whole manufacturing process, the software looks at all the support structures that will be needed to make that part. All of that is done inside one integrated digital environment — from the scanning to designing, to the topology optimizations and simulations — to see how the part will be made and what resources will be required to make that part.

Rahul Garg, VP, Industrial Machinery and SMB Program, Siemens

The closed-loop digital manufacturing discussion with Greenfield amplified several key takeaways that we were eager to showcase at the largest manufacturing technology show in North America. From further optimizing the production process before actual production begins, to leveraging digital twin technologies through an end-to-end digital manufacturing demonstration – all while keeping SaaS and sustainability top of mind.

As Greenfield concluded his tour at our booth, he witnessed the digital manufacturing momentum building within the Siemens Xcelerator portfolio of capabilities. Future-forward digital manufacturing dialogues like this are what makes us even more excited for what’s to come at IMTS 2024.