W.A. Pfeiffer grows the business with digital manufacturing [VIDEO]

W. Andreas Pfeiffer – Maschinen- und Apparatebau manufactures precision components for a wide variety of applications such as optical devices, machinery, and medical technology. This relatively small but highly-successful company competes globally with only 25 employees and 16 CNC machines in their production facility in the picturesque town of Zirndorf, Germany.

By using the digital manufacturing capabilities of Siemens Xcelerator, W.A. Pfeiffer transformed their operation, manufacturing high-quality products and continuously growing the business, despite the highly competitive global market.

Building a seamless digital manufacturing process

Operating as a small company, W.A. Pfeiffer faced difficulties in growing and increasing new capabilities at their location, as the facility cannot be physically expanded further. Andreas Pfeiffer, CEO, recognizes the challenging circumstances but knows embracing digitalization would provide its operations with a competitive edge. “The goal is to achieve higher production automation and end-to-end connectivity so that we can reduce set-up times and minimize throughput times,” said Andreas Pfeiffer, CEO.

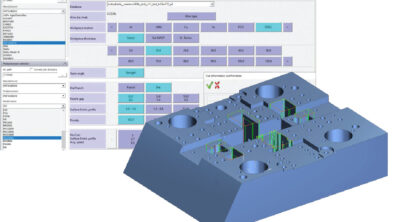

To eliminate these challenges, W.A. Pfeiffer now operates as an all-encompassing digital CAD/CAM/CNC chain to transform the business into a digital machine shop.

For W.A. Pfeiffer the Teamcenter PLM software helps with the management of all the data for the part manufacturing process, which begins with the incoming customer order. 3D data is seamlessly transferred from Teamcenter to NX CAD/CAM to generate programs for the CNC machines. Using Mcenter, formerly SINUMERIK Integrate, the CNC programs and tool lists are seamlessly transferred to production.

By integrating order planning into the digital manufacturing process, W.A. Pfeiffer witnessed immediate improvements with setup and throughput times. Opcenter APS helps them to access detailed information about production orders and monitor resource utilization.

W.A. Pfeiffer’s customer and supplier relations have significantly advanced, and internal collaboration is better streamlined by using Siemens’ range of software solutions.

High-performance machining with NX CAM

NX CAM software helped W.A. Pfeiffer to improve productivity both during the planning and in the production phase. The company leverages NX’s advanced capabilities to create innovative high-speed machining strategies and generate machine-specific NC programs using cloud-based postprocessing.

Thanks to the G-code-driven simulation in NX, engineers can digitally verify the generated operations. The advanced capability allows them to evaluate and optimize the processes before transferring them to production, saving setup time and increasing machine uptime. Siemens’ NX CAM helps the company run error-free and highly efficient part production on the shop floor.

The digital machine shop advantages

This highly successful yet lean company relies on the Siemens’ digital solutions to continuously grow and scale their manufacturing business. With the introduction of NX CAM, Teamcenter, Opcenter APS, and Mcenter, W.A. Pfeiffer achieved higher automation, seamless end-to-end connectivity, and shorter lead times.

Using advanced toolpath technologies helped W. Andreas Pfeiffer reduce the machining cycle by 25% while extending tool life. I expect that we will be able to reduce setup times by up to 50% overall.

Andreas Pfeiffer, CEO

Learn more about W.A. Pfeiffer’s expansion strategy through digital manufacturing in the video below!

Comments

Leave a Reply

You must be logged in to post a comment.

![Small manufacturers save big with digital transformation [EBOOK]](https://blogs.stage.sw.siemens.com/wp-content/uploads/sites/15/2022/07/Small-manufacturers-save-big-with-digital-transformation-e1656716503294-395x222.png)

Very good