Siemens Emerges as Leader in Discrete Manufacturing: ABI Research’s Competitive Rankings 2024

Introduction

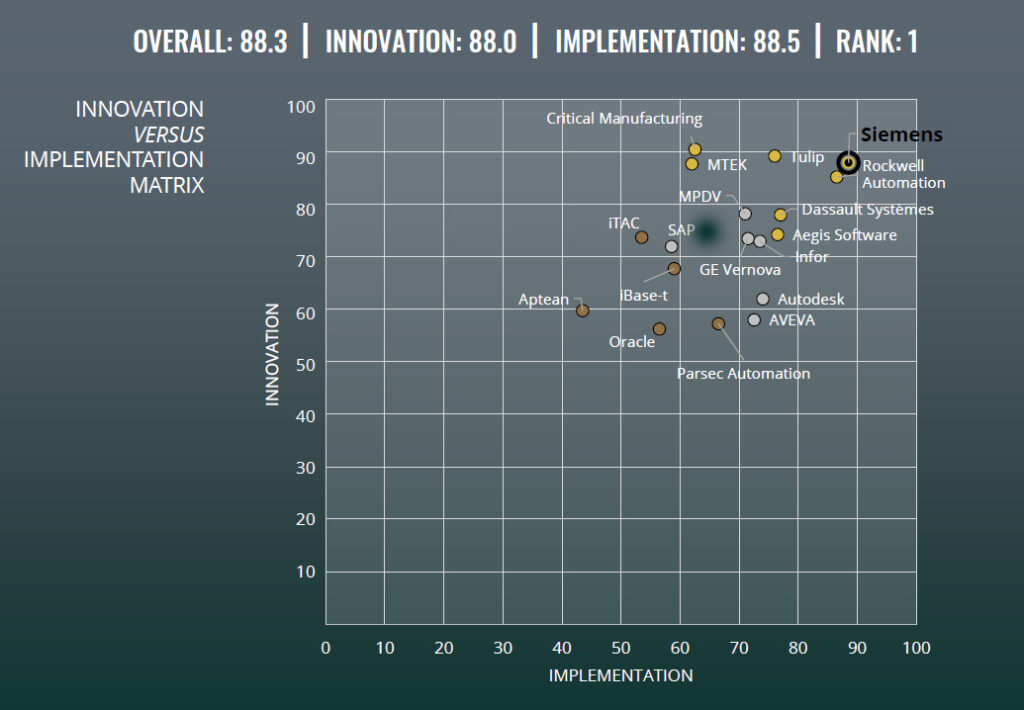

In the highly competitive landscape of discrete manufacturing, Siemens has secured its position as the overall leader in 2024, as confirmed by ABI Research’s Technology Vendor Competitive Rankings.

Siemens’ MES software, Opcenter, has been widely recognized for its innovative approach and effective implementation strategies.

As a key component of the Siemens Xcelerator platform, Opcenter offers a comprehensive end-to-end manufacturing operations solution, seamlessly integrating with various Siemens solutions.

Delivering best-in-class Manufacturing Operations Management in discrete manufacturing

At Siemens, our mission is to be a trusted partner in helping our customers deliver innovative manufacturing operations management solutions. We understand the importance of integrating seamlessly with our product lifecycle management and automation technologies to ensure the highest quality products are manufactured cost-effectively and efficiently. With our rich Manufacturing Operations Management portfolio, we empower manufacturers to thrive in the digital enterprise, supporting both life-changing and life-sustaining product development. Furthermore, we offer flexibility in supporting various deployment scenarios, whether it’s single-site or enterprise-based, on-premises or cloud-based.

Innovation journey – six pillars for success

Our commitment to innovation is evident through the six main pillars that drive our journey towards excellence in manufacturing operations management:

- Reducing the total cost of ownership for applications.

- Improving application performance by infusing artificial intelligence.

- Supporting streamlined upgrades with zero downtime.

- Simplifying deployment and application management.

- Enhancing scalability, performance, and user experience.

- Optimizing uptime and reducing deployment costs, while improving portfolio integrations and observability.

MENDIX low code – revolutionizing user interface development

The adoption of MENDIX low-code technology brings a significant reduction in total cost of ownership in discrete manufacturing by accelerating the speed and efficiency of building user interfaces. Customers no longer have to spend excessive resources on maintaining and developing interfaces independently. In fact, we’ve observed more than 50% faster UI development with MENDIX integration.

Siemens named as top innovator for discrete manufacturing MES

Siemens’ Opcenter is a testament to our commitment to innovation. This comprehensive MES solution supports multi-plant architectures, reducing the burden on regional IT teams and the overall Total Cost of Ownership (TCO). It seamlessly integrates with Teamcenter (PLM), Simcenter (simulation), Insights Hub (data analytics), Opcenter Quality Management System (QMS), and Tecnomatix (production process optimization through digital twin modeling). Furthermore, our close collaboration with AWS has enhanced our innovative capabilities, enabling the creation of AI applications using AWS Bedrock’s intuitive drag-and-drop functionality. This groundbreaking feature is set to revolutionize the way our customers operate, saving them valuable time and resources.

Siemens named as top implementer for discrete manufacturing MES

On the implementation front, Opcenter sets itself apart with its comprehensive out-of-the-box (OOTB) MES solution, designed to support multi-plant architectures. Coupled with Siemens’ extensive customer base, competitive deployment times, and seamless integration capabilities, manufacturers can rapidly scale and deploy new production lines with templatized industry best practices. Our commitment to driving value across all segments of the manufacturing industry is exemplified by Opcenter X, a cloud-hosted version of the solution tailored specifically for small and medium-sized (SMB) manufacturers.

To delve deeper into this groundbreaking research, we invite you to download the report and discover how Siemens is revolutionizing the future of discrete manufacturing operations management.