Extend digital efficiencies across the supply chain – Part 1

Welcome to the first in a series of three blogs about extending digital efficiencies across the supply chain.

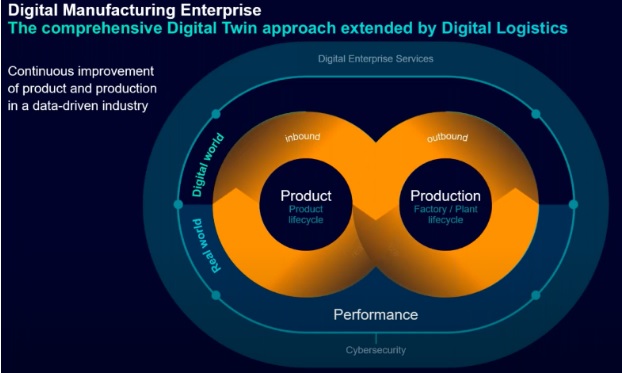

By implementing modern digital manufacturing software, production facilities have made great strides to increase throughput, decrease operational expenses and add to net profits. Key to these benefits is real-time visibility into shop floor operations, which the digital systems provide to stakeholders throughout the manufacturing enterprise. What if this visibility is extended beyond the factory walls to the full supply chain? What impact might this have on throughput, expenses and profits? This kind of visibility is the objective that Siemens Digital Industries Software has realized with our integrated digital manufacturing and supply chain solution, which connects the comprehensive digital twin with digital logistics.

In this blog series, we explore how integrating digital logistics amplifies the value of the comprehensive digital twin. We will also look in greater detail at how digital manufacturing and digital logistics software work together to streamline supply chain workflows and enable companies to more efficiently adapt to unanticipated disruptions.

Don’t miss our other posts in this series:

Extend digital efficiencies across the supply chain – Part 2

Supply chain convergence: Resilient design and execution with Siemens solutions

Evolution toward an integrated digital manufacturing and supply chain solution

For many industries, digital manufacturing software has transitioned from a beneficial option to a competitive necessity. Disruptive technologies like electrification and societal changes like demands for sustainability impose new materials and processing requirements. Innovation to meet these demands often results in greater product and process complexity. “Lot size one” and other mass customization trends magnify the complexity. As a result, paper- or spreadsheet-based manufacturing management is simply not able to keep up. Many companies have adopted a powerful solution from the Siemens Opcenter manufacturing operations management (MOM) software portfolio, which enables them to operate efficiently, achieve production goals and meet customer demands even in the midst of these changes. To support manufacturing efforts with the speed and agility of digitalization, Opcenter leverages a comprehensive digital twin – a highly realistic virtual representation of a product and its manufacturing processes – and a digital thread that shares dialogue and activities across digital systems.

Beyond an individual manufacturer’s facilities, growing volatility and new disruptions demand software that addresses logistics needs. Adverse events around the globe continue to disrupt the flow of materials and goods and expose supply chain vulnerabilities. Catastrophic weather events, ongoing health-related lockdowns and geopolitical conflicts exacerbate labor and logistics issues at major ports and along major rail and road transportation routes. Escalating costs compound logistics challenges; a $300 container charge just a few years ago has mushroomed to $8000! Manufacturers are adding alternative vendors to their supply chains and seeking ways to keep disruptive events from interfering with production and delivery schedules.

Siemens’ logistics solution is a mature product that addresses issues arising outside the factory in shipping, transportation and delivery. It gives companies visibility along the supply chain and enables logistics optimization in terms of cost, speed, CO2 emissions, or a combination of these factors. Because the solution is modular, users can start with one set of functions, gain speed and success, and then extend to other functions over time.

In the case of Swiss company Meraxis, a global supplier of plastics, Siemens’ logistics solution supports the company’s digital transformation with full transparency into an integrated supply chain. The solution affords Meraxis visibility into risks associated with certain shipments, giving the company the opportunity to address potential issues before they occur. As a result, the cost of extra trips and expedited transportation has been reduced substantially.

Siemens’ manufacturing and logistics solutions, each individually, have boosted productivity, and now manufacturers have an opportunity to achieve the next level of productivity through a combination of these two powerful software products.

Learn more about Meraxis directly from Volker Albrecht, the CEO of Siemens Digital Logistics, in this extract from a webinar entitled “Planning for a more resilient supply chain”!

Would you like to learn more about how Opcenter APS can give you a competitive advantage in Supply Chain convergence?

Read our eBook “Supply Chain Management Planning – challenges and Opportunities” to get more insights!