Can a digital twin predict corrosion?

In a word, yes, with a digital twin of cathodic protection (CP) systems. Corrosion is an ancient enemy that eats away its assets and can cost billions of dollars annually.

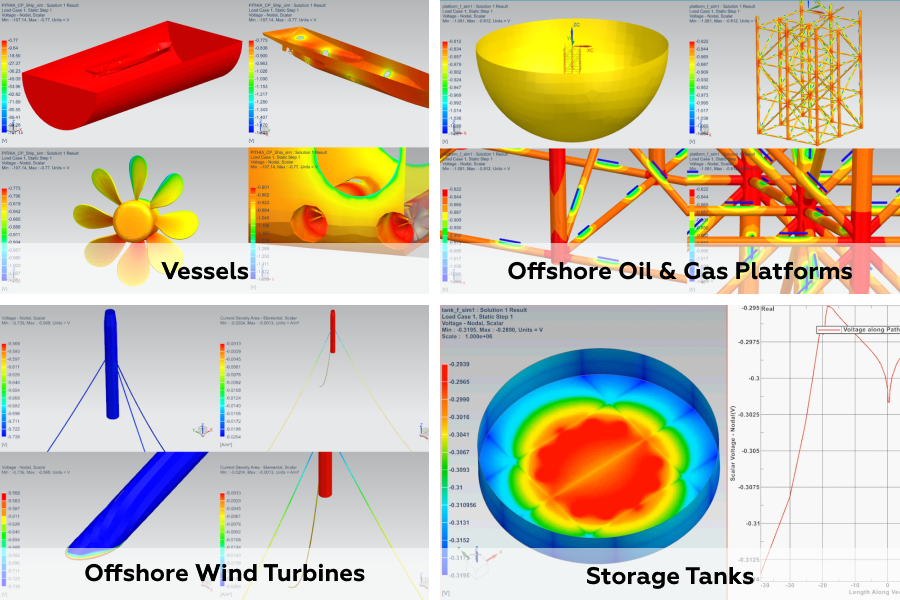

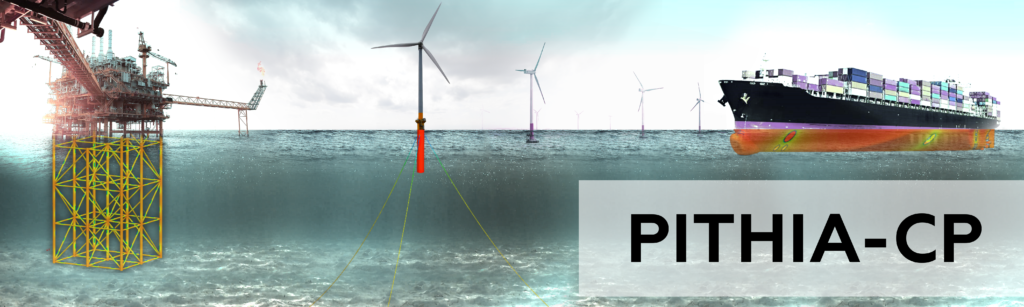

CP aims to eliminate a metallic surface’s corrosion by converting it into the cathode of an artificially made electrochemical cell. Cathodic protection is often used in offshore installations of wind turbines, drilling rigs and vessels, onshore installations including oil and gas storage tanks, and pipelines, and concrete installations usually of steel reinforcements. All these structures have metallic components exposed to corrosive environments (see ISO9223).

Mitigating corrosion is essential from both an operational and cost standpoint. Ignoring corrosion can shorten structure lifespan and increase maintenance costs leading to loss of critical material and increased human effort. Cathodic protection prevents premature corrosion and reduces the overall corrosion process.

Numerical modeling for CP systems in PITHIA-CP

Although there are a few numerical solutions that have been around for several years, this is the first time CP has such a complete tool with the Siemens and PITHIA-CP portfolios. In collaboration with Siemens Digital Industries Software, Software and Technology partner, FEAC, is revolutionizing the way marine, oil and gas, and energy and construction companies leverage the power of simulation to optimize the safety and expand the longevity of their investments, both onshore and offshore.

Engineers at FEAC created PITHIA-CP, a unique solution for cathodic protection computer-aided engineering, now integrated as an add-on module to the Simcenter™ software portfolio.

The importance of numerical modeling is highlighted by the fact that classification societies such as DNV-GL highly recommend the utilization of digital twins of CP systems (DNVGL-RP-B101)

Why the boundry element method?

The dominant competing solution is the finite element method (FEM), which has certain limitations in problems dealing with infinite/semi-infinite domains. PITHIA-CP is based on the boundary element method (BEM), which reduces the dimensionality of the problem. It requires the discretization of the boundaries only in contrast with the FEM where the volume of the, e.g., sea or water, must be discretized.

PITHIA’s unique BEM solver

But the method itself does not guarantee its efficiency. The critical turning point of PITHIA-CP lies in its solver, which is the only one to handle complex models with more than 1 million degrees of freedom (DoF) reducing the need for simplifications and modeling assumptions, allowing the confidence and accuracy of the computed results. Implementing innovative numerical techniques also offers drastically faster solution times while minimizing the computer hardware requirements.

Modeling environment and intuitive workflow

Through the partnership between FEAC and Siemens, engineers dealing with cathodic protection can now enjoy a modern, CAD-centric, highly efficient, multi-discipline modeling environment. The combination of PITHIA-CP with Simcenter 3D can improve user experience and workflow while providing highly accurate results.

“We are pleased that FEAC Engineering has joined the Siemens Solution Partner Program as a Software and Technology Partner for Simcenter 3D software. FEAC’s PITHIA-CP is a world-leading Boundary Element solution for cathodic protection, which can provide our customers complementary solutions that add value to their software investment. Through this partnership, engineers dealing with Cathodic Protection can now enjoy a modern, CAD-centric, highly efficient, multi-discipline modeling environment”

Koen De Langhe

Director Product Management

Siemens Digital Industries Software

Charilaos Kokkinos is the Technical Manager at FEAC Engineering, a solution provider and technology partner. He is a numerical-simulation enthusiast interested in engineering, new technologies, digital twins, innovation, and entrepreneurship.

FEAC is a Siemens Digital Industries Software Software and Technology Partner. Software and Technology partners are leaders in their domain and leverage the open Xcelerator portfolio to provide customers with a comprehensive set of integrated solutions. Visit our partner pages to find out more or to become a partner.