How to use checklists for DO-254 verification

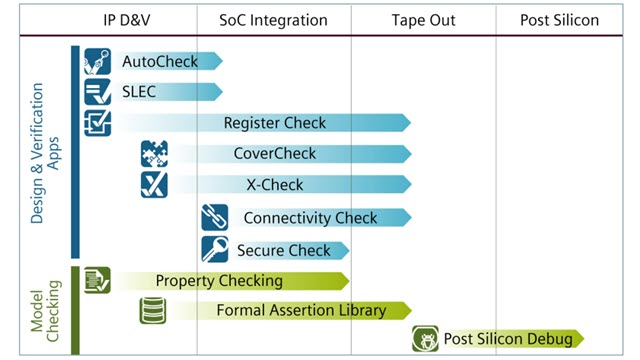

Document DO-254 provides aerospace and defense companies with the needed guidance to develop and verify airborne electronic hardware. Some clients use products like Siemens’ Questa to fulfill vital verification objectives of DO-254 such as hardware behavior simulation and code coverage as a means for elemental analysis. But did you know a simple checklist can also be an effective DO-254 verification tool?

No one enjoys ticking boxes on checklists for reviews. So, are they really necessary? Frankly, no. But for practical reasons, I’d say yes. As a verification tool, checklists can aid reviews and provide evidence of compliance with DO-254 objectives.

Many of the verification objectives in DO-254 are satisfied by reviews and analysis. Therefore, when you perform assessments to meet DO-254 objectives, you need to provide evidence that they were performed with the correct independence and on a controlled, retrievable version of the data under review. You also need to show that each objective was evaluated and any required actions were recorded and resolved in a revised version of the data. Checklists provide an excellent means to do this.

Now, if you’re going to take my advice and use checklists, here are a few helpful hints:

- Checklists aren’t just documents. They act as evidence of an independent review of a process or artifact

- Annotate and connect checklist items to the development and verification planning standards and activities that must be performed

- Keep checklist size manageable. Create one checklist per document or process needing review. The goal is to remind reviewers to check items required by the standards and activities.

- Remember to include the names and roles of the reviewers and the version and title/number of the items under review (including any other items needed to evaluate the data item such as trace matrix, standards, etc.)

- Confirm that actions recorded from the review are tied back to the questions on the checklist. This ensures you can provide evidence that all review evaluations were considered and actions closed.

- Show how each action was resolved and which version of the data item was resolved. It is helpful to have checklists that account for iterative reviews.

Most importantly, organize all checklists so they are readily available when the auditor asks for them. Remember, these are verification outputs and should be treated with the same formality as test results.

You could certainly develop checklists for your program yourself by reading/reviewing DO-254 and all the new policies that add to the expected guidance. It’s doable. Alternatively, you could consider a complete and extensive set of premade checklists written and reviewed by certification experts.

To better understand verification in the context of DO-254 programs and how to use both Questa and checklists, read this white paper co-written by Patmos Engineering Services and Siemens. If you’re using Questa for verification in your DO-254 program and looking for certification advice, contact us via the Patmos website.

About the author

Tammy Reeve, named one of “The Most Influential Women in Aerospace” by SAE International, is an independent designated engineering representative for the FAA and other worldwide agencies. As president of Patmos Engineering Services, she specializes in both DO-254 and DO-178C for airborne hardware and software. She has over 30 years of experience in avionics development and certification.

Patmos Engineering Services is a Siemens Software and Technology partner that helps clients achieve first-pass and ongoing success in their compliance programs. Patmos offers training, consulting, certification, and engineering support for DO-254 and DO-178C programs.

Partners who build solutions

Software and Technology Partners use the Siemens Xcelerator portfolio and its flexible open ecosystem to build technologies that complement the comprehensive digital twin and provide customized solutions for our mutual customers. These partners often develop, sell, support and market hardware and software solutions that are interoperable with Siemens products and ensure infrastructure compatibility.

Find a partner to help you build your digitalization solution