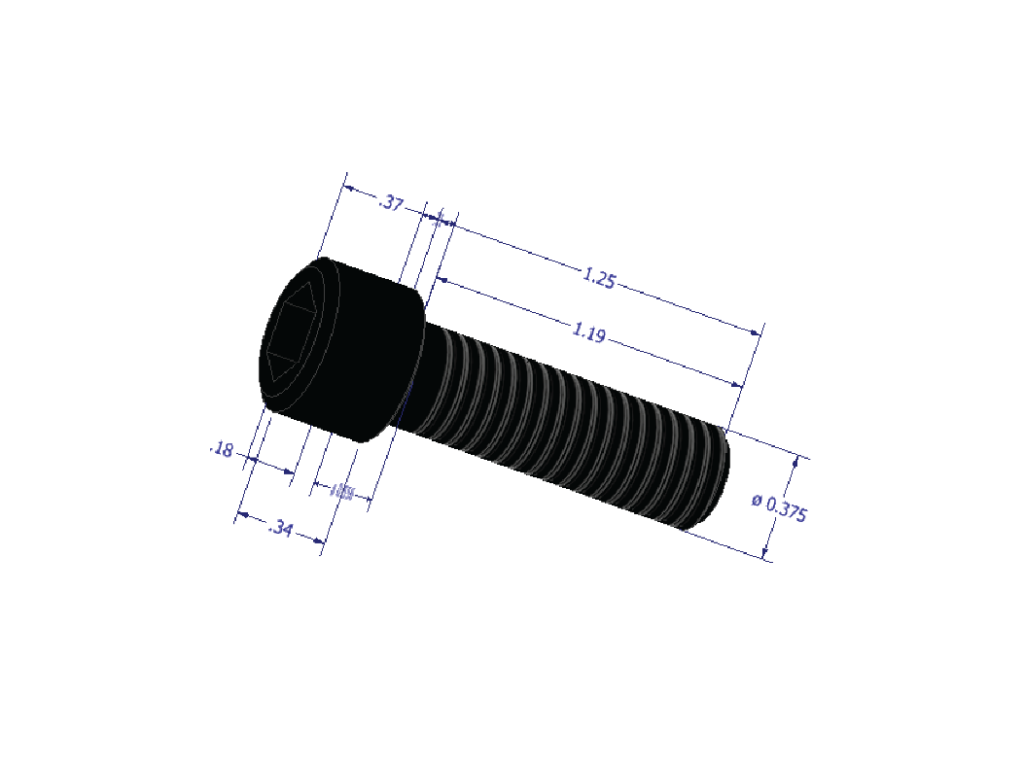

How compliant are your fastener libraries with industry standards?

Companies demand industry-standards and industry-standard parts are no exception. Industry-standard parts are required in aerospace, automotive, and marine industries, among others. If you design products in NX or Solid Edge that require industry-standard parts, it’s essential to understand what they are and when to use them.

What are industry standard parts?

Industry standards are established by standards developing organizations and are commonly referred to as SDOs. A few well-known SDOs are AIA, SAE, and ASME. These SDOs compile the standards into PDF specification sheets for engineering, manufacturing, and procurement departments.

The U.S. government often requires standard parts in designs for military and defense projects. For example, Military Specification (MIL-SPEC) is a common standard for defense contracts.

Why are industry standards necessary?

Industry standards ensure that the bolts in landing gear and engines don’t fail. They ensure that the fasteners holding the wheels on your car don’t snap while you drive. It’s easy to see why industry standards are critical for safety. When engineers use industry-standard specifications, they eliminate much alternative rigorous testing.

It’s essential to make sure you understand your industry’s standards and not take any shortcuts around meeting the requirements. You don’t want your company to be in the news because an integral fastener snapped when proper standards were not used and documented. It is not only critical for the physical product to use the standard; it should also be represented in the product’s digital model or engineering design to ensure documentation and compliance.

Stay compliant with industry standards

The best way to ensure compliance with the standards is to access the PDF spec sheets for each standard your application requires. It also follows best practices to maintain accurate CAD models for each part in an assembly.

Companies often use NX or Solid Edge to create industry-standard CAD model libraries themselves, which are stored inside Teamcenter. The issue with manually creating industry-standard libraries within Teamcenter is that standards constantly change. These changes to the standards open the door for engineers to use non-compliant CAD models and data within their designs.

One way to ensure the models that engineers use are accurate is by giving them access to 3D CAD models certified by the SDO. You can find out more information about obtaining certified 3D CAD models from AIA, SAE, and ASME.

Joseph Lewin is the Product Marketing Manager for PARTsolutions software. His goal is to enable engineers to work more efficiently by providing resources and education about improved engineering processes.

CADENAS PARTsolutions is a Siemens Digital Industries Software Software and Technology Partner. Software and Technology partners are leaders in their domain and leverage the open Xcelerator portfolio to provide customers with a comprehensive set of integrated solutions.