Supplyframe’s DSI unlocks new capabilities for Teamcenter customers

Since Supplyframe’s acquisition by Siemens in 2021, we have created numerous synergies that unlock transformational benefits for customers using both companies’ solutions.

Now, we are pleased to announce a new integration between Supplyframe’s Design-to-Source (DSI) SaaS solutions and Siemens Teamcenter PLM software, allowing for reduced cost and risk across the electronics product lifecycle.

Lifecycle management that brings electronics to market faster

Siemens Teamcenter is a market-leading product lifecycle management solution that leverages digital twin technology to optimize processes across designs, systems, software, simulation and visualization. Pair this with team-wide visibility and collaborative toolsets, and it’s clear why Teamcenter is a leading choice among fast-moving companies – from start-ups to global enterprises.

Supplyframe’s DSI Solutions provide global electronics manufacturers with real-time supply market intelligence and design insights at the component, product, and commodity levels for the value chain. These solutions help teams make data-driven decisions earlier than ever in the product lifecycle while avoiding unforeseen risks and reducing costs before they are “locked in.”

As part of the new Teamcenter and Supplyframe DSI Solutions integration, users of both solutions can access their BOMs in either platform with a single click. While in Supplyframe DSI Solutions, engineers and sourcing professionals can process line items directly from Teamcenter, extending the process from engineering to cross-functional risk and cost trade-off analysis as well as optimized sourcing event management for procurement teams.

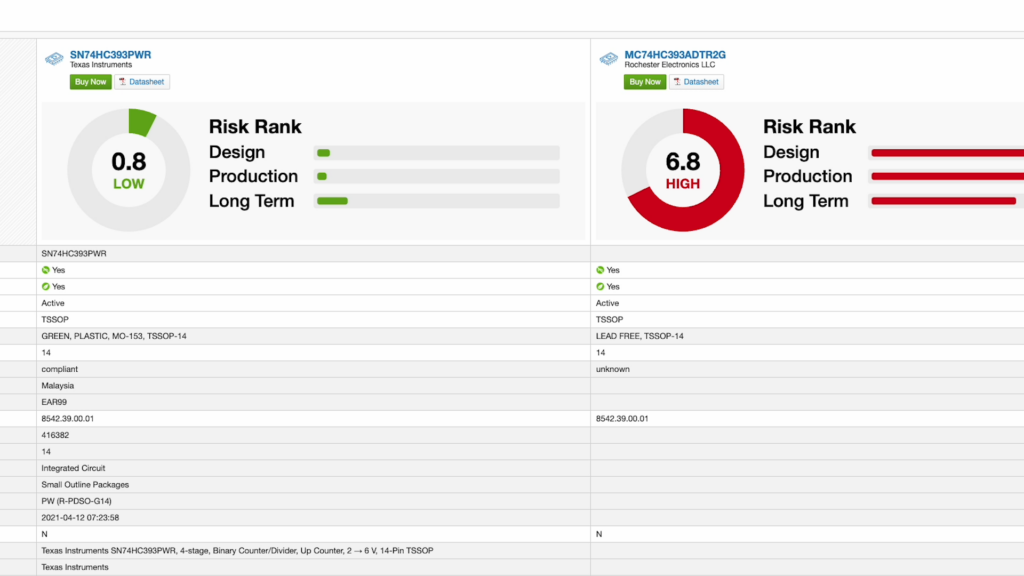

Users can cross-reference manufacturer part numbers to identify parts with potential risk factors like extended lead times, price volatility, or part lifecycle status. They can also identify potential alternates as needed with suggested examples that match form, fit, function, and detailed parametric attributes. This allows users to clean and validate engineering bills of material (BOMs) in a fraction of the time with Supplyframe NPI, and digitally manage new RFQs and sourcing events with all suppliers in a closed-loop process with Supplyframe DirectSouce.

With intelligence on over 600 million standard components and across 400 sub-commodities driven by digital engagement of over 15 million engineers and supply chain professionals, the DSI Network allows Teamcenter customers to source smarter and connect their BOMs to the broader electronics value chain through the product lifecycle.

Connecting Supplyframe’s Intelligence to your design process

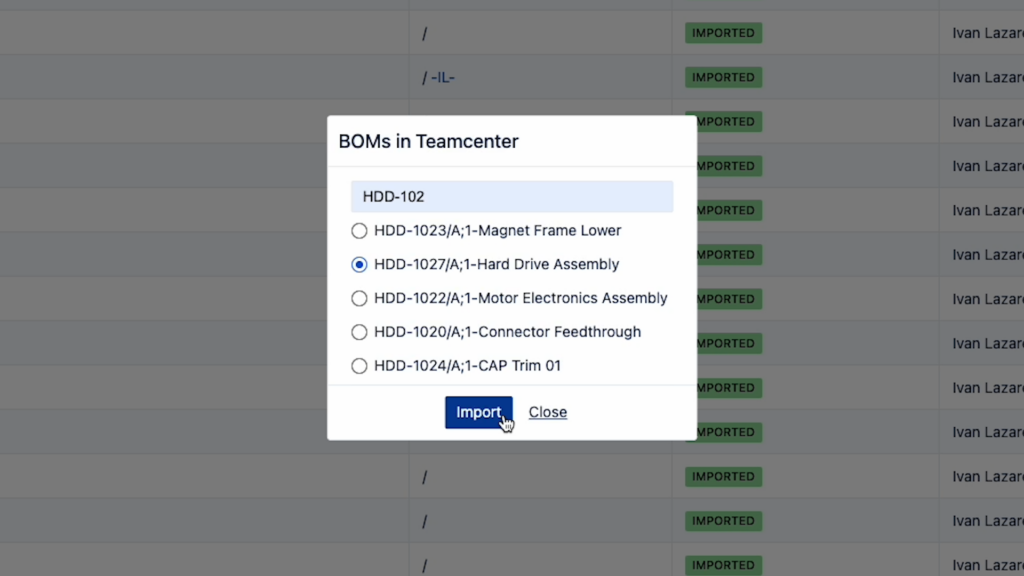

Supplyframe and Teamcenter users can access their BOMs quickly and efficiently as part of this new integration. When using Supplyframe DSI Solutions, the dashboard now includes an option in the top right corner labeled “Import From Teamcenter.”

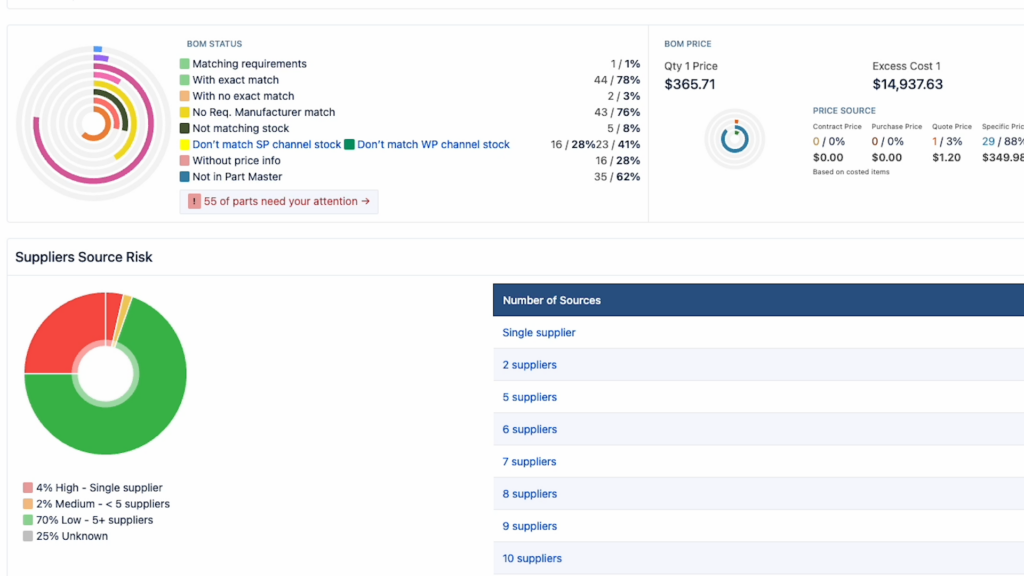

This opens a menu to select which active BOM to import. Once selected, the line items and selected parts appear in your Supplyframe NPI dashboard. A quick analysis immediately identifies any issues with part numbers and highlights risks surrounding cost or availability using the proprietary “Risk Rank” metric.

Parametric data on each line item is available, allowing insights into market fluctuations, lead times, pricing and more.

Give your teams a bird’s eye view of the BOM’s health and offer alternate part suggestions for any line items that present more than a baseline level of risk, either immediately or later in the product lifecycle.

Once the BOM has been cleaned and validated, a function labeled “Open in Teamcenter” on the Supplyframe dashboard will import the updated line items back to the Teamcenter dashboard. Similarly, it is possible to begin the process here for those working within the Siemens solution first. Additional validation for alternate part selection or reflecting engineering change orders based on new risk insights can now be tightly orchestrated.

When the BOM is ready for the next steps, Supplyframe allows users to create an RFQ and send the finalized part list to suppliers. This allows teams to leverage an integrated and streamlined approach that provides vital intelligence where needed most to avoid cost and risk later in the product lifecycle.

Looking ahead

This is the first phase of Supplyframe’s integration into Teamcenter, and it joins other recent developments in an ongoing initiative to solidify Supplyframe as the nucleus of Siemens’ digital marketplace strategy through the application of Supplyframe’s leading intelligence and complementary SaaS solutions.

For more, discover how Supplyframe’s Design-to-Source Intelligence was also recently integrated into Siemens’ Xpedition software and view our partner page as part of the broader Siemens Xcelerator open digital business platform.

About the authors

Richard Barnett is Chief Marketing Officer at Supplyframe. He brings more than 20 years of experience in strategic marketing, sales, and product management of innovative supply chain software solutions.

Bradley Ramsey is the Content Marketing Manager for Supplyframe, where he assists the global marketing team in showcasing how outside-in intelligence can prepare electronics value chains for what’s next, be it challenges or opportunities.