Why do production planners still use Excel?

It’s mind-boggling why so many manufacturing production planners still use Excel instead of software created specifically for scheduling. My work with production planners over the past 30 years suggests that while Excel doesn’t fully meet their scheduling needs, it does solve the problem in the short-term – and quickly since production planners don’t have the time to find and push for more sophisticated tools. And when they do, they are typically met with organizational resistance.

What about ERP?

The need to consolidate disparate systems led manufacturers to purchase enterprise resource planning (ERP) systems. As ERP systems were rolled out, the production planner, under the mandate that the old tools and disparate systems should disappear, would do their best to use the scheduling tool native to that ERP system. But because ERP scheduling tools typically can’t model all the manufacturing constraints, the schedule would not be accurate which naturally caused the production planner to abandon the tool and return to using Excel or other manual processes. IT Executives don’t want to believe or admit that their ERP selection isn’t viable or able to solve production scheduling, so they frown on the production planner and rarely pursue finding the necessary tool to get the job done.

Bring on advanced scheduling experts

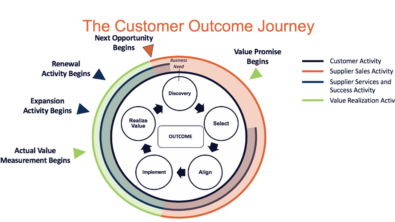

Sound familiar? I’ve heard this story dozens of times across many industries as has my colleague, Joao Laner. In Laner’s blog, Improving Profitability with Advanced Scheduling, he talks about how using APS software can help reap efficiency and profitability improvements from using the standard, functions without needing to create complex rules to start seeing an immediate return on investment

Industry expert and author of The Little Blue Book On Scheduling, Mike Liddell, provides his insights on this topic based on 20 years of work helping hundreds of manufacturing clients transition from Excel to advanced scheduling tools.

It is curious why production planners still use Excel. Thanks to Smart Expert partners like Lean-Scheduling, who specializes in APS, companies seeking help to get out of the manual processes and addiction to Excel can learn the value that dedicated software provides to support their advanced planning and scheduling requirements.

Dave Snyder is a Manufacturing Operations Management (MOM) Partner Sales Executive with Siemens Digital Industries Software. Dave has 30 years of experience building, implementing and selling advanced planning and scheduling solutions in 22 countries. For him, advanced planning and scheduling are essential to achieving value from the MOM portfolio.

Comments