Podcast series: Smart manufacturing (Part 1) – industrial-machinery

Summary

The landscape of industrial machinery and manufacturing has seen an innovative overhaul of technological advancements.

Siemens is one of the largest industrial automation supplier in the world, with a unique position in the software side. They have been a leading provider of industrial automation for a number of years so they understand how technology needs to be integrated into the machinery.

Today, in our first podcast in this series, Bill Davis and I, we’re discussing how machinery manufacturers are gaining a competitive edge by implementing smart manufacturing.

Bill Davis is the Director of Industrial Machinery & Heavy Equipment Solutions at Siemens. He has a Mechanical Engineering Degree, Bachelor in Science Degree from Milwaukee School of Engineering, with a Masters in Business Administration from Marquette University. In the course of his experience, he has gained a lot of skills with regards to CAD and PDM, as well as operations management.

Listen to the First Episode of Siemens PLM Podcast series to learn how machine manufacturers are maximizing profits, and the industry trends driving the adoption of this innovative technology.

Questions I ask:

· Within that 30-year span of your career, how long have you been focused on smart manufacturing? (02:28)

· What is smart manufacturing? (03:01)

· In what way is Siemens PLM implementing smart manufacturing into companies and into manufacturers? (06:08)

· In looking at just the trends in this industry, how do you see Siemens with the machine trends and aligning that with smart manufacturing? (08:38)

· How are you seeing trends changing in the way customer purchases a machine? (12:52)

In this episode, you will learn:

· Bill Davis’s background and career. (01:15)

· Smart manufacturing at the product level. (03:55)

· Smart manufacturing at the machinery level. (04:32)

· What adaptability means, in terms of smart manufacturing. (09:42)

· What extendability refers to, in terms of smart manufacturing. (11:22)

Connect with Bill Davis:

The landscape of industrial machinery in manufacturing is seeing an innovative surge of technological advancements based on smart manufacturing. This is in response to the daunting task of validating and managing modern manufacturing and assembly operations to achieve a premium level of quality while optimizing cost.

Join us in this first of four podcasts on Smart Manufacturing by Siemens Digital Industries Software, a solution for industrial machinery. We are joined by our expert Bill Davis, Director of Industrial Machinery and Heavy Equipment Solutions at Siemens.

Bill’s expertise spans over 30-years, including both the industrial machinery and heavy equipment industries. As an engineer, he has active participation in CAD, PLM, PDM, the digital enterprise and the digital thread. Listen to his evaluation of the manufacturing industry, assessing the Smart Manufacturing environment and forecasting innovative solutions.

Smart manufacturing and machining

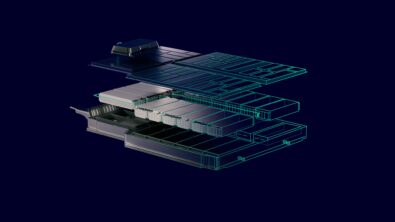

Smart manufacturing allows a company to extract information and drive it into manufacturing operations, including CNC programming or inspection and assembly processes. This information formulates a digital twin at the product level.

In machining, manufacturers are asking for additional content, sensors and feedback on how production and manufacturing processes are executing, for leveraging into the manufacturing digital twin. For example, suppose an inspection process is used when making the machining tool. Adding that inspection data from the machine tool creates traceability from design to manufacturing and a closed-loop process based on a high-fidelity digital twin. The next crucial step is linking together the digital twin of the product with the digital twin of the machine.

The manufacturing industry – process and trends

A comprehensive solution assists to realize every step in the manufacturing process: idea creation, developing the product via machining, executing in manufacturing, and extending across the entire service life based on the digital twin. This enables machine manufacturers and designers to both create value, drive down cost and compress delivery schedules. Moreover, it allows for closing the loop faster between manufacturing operations and engineering.

The manufacturing industry is in a continuous process of change due to these trends:

- Connectability – Customers expect machines to communicate with the other machinery in the plant via a machine builder (OEM).

- Adaptability – With all the information generated by sensors and capabilities, smart machines can recognize changes in upstream products and processes and adjust to these dynamic operating conditions. This is a type of artificial intelligence for machinery, which creates customer expectations for highly flexible machines capable of producing multiple types of products.

- Predictability – An increasing emphasis is on the simulation and predictability of a machine’s performance in the field requiring a high-fidelity digital twin of the machine. This process is more complex with higher speeds, more significant use cases and more sophisticated machinery.

- Extendability –Another key trend is extending the life of a machine in the customer facility, with predicted maintenance and adaptive performance. The objective is to create more value for a manufacturing customer and to optimize the cash flow.

Another major shift in utilizing a smart manufacturing approach is production-as-a-service, where customers buy machine capacity instead of investing in purchasing machinery. This emerging dynamic is primarily happening with equipment manufacturers that lease machines. The difference is in paying for performance only when the machine is being used.

Therefore, the OEM has a vested interest to ensure that the machine is always running optimally. If the machine needs to be upgraded to meet production requirements or requires general service, the OEM is responsible for correcting those performance improvements or downtime issues and incentivized to get it back up and running quickly to continue the cash flow.

As you can see in this brief overview, manufacturing is seeing radical changes in the dynamics of both hardware, products and processes based on rapid technology advancements.

To learn more, listen to the podcast on the following apps: Stitcher, Spotify, Castbox, TuneIn. and RSS Feed.

This concludes the first blog and podcast in this series on Smart Manufacturing and the trends affecting the industry. View the second and third blog in this series.

Listen to podcast02 and podcast03 and podcast04.

About the author:

Bill Davis is the acting Industrial Machinery and Heavy Equipment Industry leader for Siemens Digital Industries Software. His experience and insights have been acquired from a career spanning 30 years in engineering and operations management with machinery and heavy equipment companies. Bill holds a master’s degree in Business Administration from Marquette University, with a concentration in Operations Management and Strategic Marketing, as well as a Bachelor of Science degree in Mechanical Engineering from Milwaukee School of Engineering.

Digital Transformation Podcast

The Digital Transformation: Solutions for Industrial Machinery Podcast by Siemens Digital Industries explores the advantages of smart manufacturing, a digitalized product development strategy and the solutions it offers for the Industrial Machinery industry.

Digital Transformation Podcast

The Digital Transformation: Solutions for Industrial Machinery Podcast by Siemens Digital Industries explores the advantages of smart manufacturing, a digitalized product development strategy and the solutions it offers for the Industrial Machinery industry.