The Next Leap for Electric Vehicles with Will Graylin, Indigo Technologies – Part 2

Wheel motors, active suspension and composites combined make a safe, roomy, sustainable, smooth riding electric car

The EV market is growing at a very fast pace.

As the demand for electric cars continues to grow and more companies join the industry, the EV market is becoming more competitive than ever before. Despite the presence of big companies with deep pockets, smaller start-ups are playing a critical role in moving the industry forward through disruptive innovations.

It’s not just the hunger to get a game-changing car that is pushing startups. It’s also the freedom to explore new features and new ways of doing things with little fear of failure. They’ve extended the competition field from speed and acceleration to other aspects such as comfort, safety, cost, and environmental friendliness.

In this episode, the second part out of two, Ed Bernardon interviews Will Graylin, a seasoned innovator who is the CEO of both an electric vehicles company Indigo, and a digital wallet company OV Loop. He’ll help us understand what sets their car apart from other EVs and conventional cars. He’ll also share with us what he thinks the future holds for the EV industry.

Some Questions I Ask:

- What makes your electric car unique? (01:05)

- Why should one buy your car? (07:46)

- Why does a Project Alpha car only have 3 wheels? (11:39)

- How does an Indigo car compare to conventional vehicles in terms of speed and acceleration? (13:26)

- How do you incorporate safety and still get a lot of room on the inside of the vehicle? (17:10)

- Do you think that once autonomy matures, it will play a role in some of the vehicles? (24:56)

What You’ll Learn in this Episode:

- How the robotic wheel and passive spring work to keep the vehicle stable (04:53)

- The importance of the robotic wheel system (06:59)

- Comparison between a Bravo car’s operating cost against that of other cars such as Tesla (09:45)

- The meaning of primary and secondary safety when evaluating cars (14:48)

- How the company utilizes composite materials to keep the cost down (19:32)

- The company’s view and approach to autonomy (22:17)

Connect with Will Graylin:

Connect with Ed Bernardon:

Ed Bernardon: It seems everyday there’s more news of advancements in the electric vehicle market with industry changing tech constantly lurking just around the corner. What may come as a surprise though is that major breakthrough don’t always come from large car companies like Tesla or GM, sometimes innovation is the brainchild of a smaller company you may have never even have heard of before like Indigo Technologies.

In Part 2 of my conversation with Will Graylin CEO of Indigo Technologies we delve deeper into the tech that’s behind their innovative EVs. EV’s that come in a variety of sizes that fill the gap between micro mobility like scooters or eBikes, and full-size cars. Will and I talk wheel motors, active suspensions, and how incorporating this tech into the wheels of their Project Alpha sedan makes possible a roomy comfortable interior, even in a smaller affordable EV.

— intro music–

Welcome to The Future Car podcast. I’m your host, Ed Bernardon. And today we continue my conversation with Indigo CEO Will Graylin. He’s a visionary, and he’s making a whole new set of vehicles possible based on a unique set of technologies that we’ll discuss as well as how autonomy will play a role as Indigo continues to innovate. I’d like to welcome back Will Graylin from Indigo to The Future Car podcast.

Ed Bernardon: You’ve talked a lot about the wheel in hub, suspension, and actual motor itself. So, there’s the wheel, there’s a unique way of charging, and then there’s also the battery management system. These are, it sounds like, your three key technologies upon which you build, that helps make your vehicles unique. Can you tell us about those technologies and what makes them so unique?

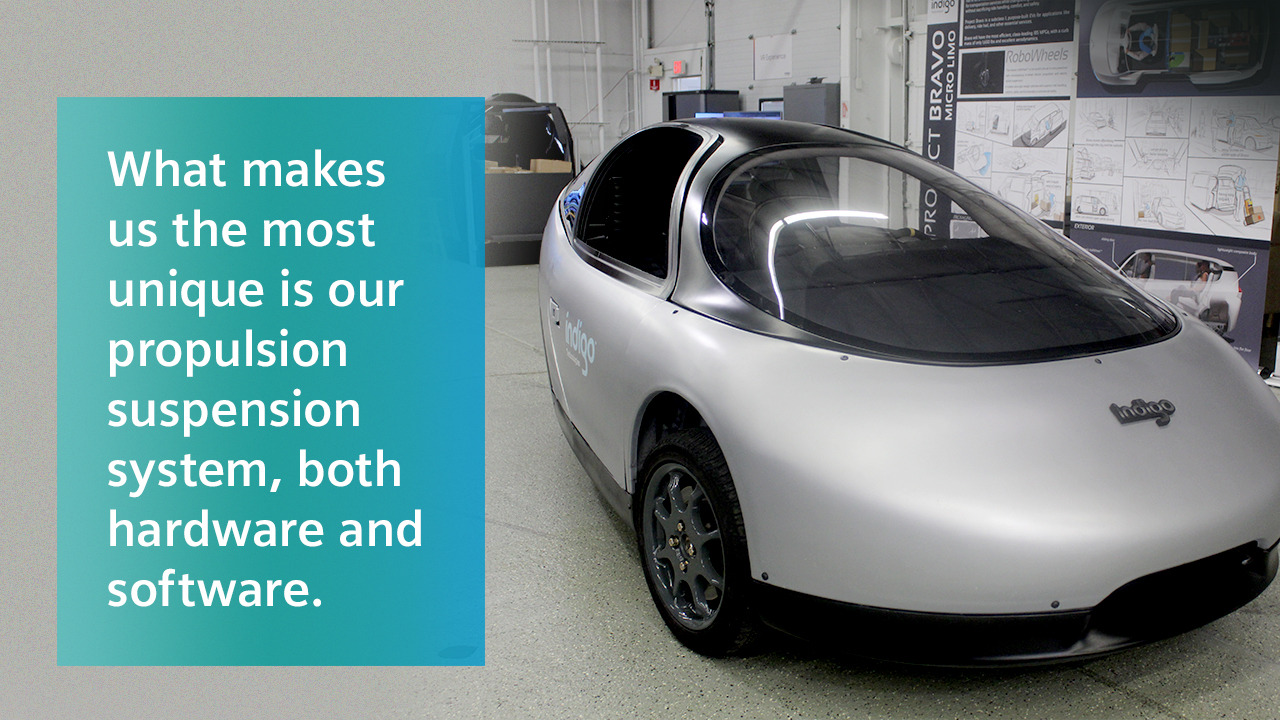

Will Graylin: I think what makes us the most unique is our propulsion suspension system, both hardware and software. And our ability to basically not only have the motor and active suspension in each corner of the vehicle, we allow the sensors to be able to detect to keep the vehicle super stable and super comfortable, and to be able to react in millisecond levels to the ground conditions, whether it’s potholes or speed bumps or conditions on the road that helps you not only with comfort but also with handling. So, for example, when you’re turning, we can actually help you lean into a turn to minimize the roll of the vehicle. So, that level of performance is all hardware and software. And then on top of that becomes what we call the top hat on top of the platform. So, the top hat – you could build a top hat that is only used for delivery with no seats at all except for the driver seat. We create a center driver seat that has two sliding doors on each side. So, that means I, as a delivery driver, can get in and out on both the left or the right. And a lot of people don’t consider the day in the life of. And I went to drive for Amazon for a day to experience what an Amazon Flex driver really experiences from pickup at the warehouse to going through and drop off and delivery. It took me four and a half hours, where it probably take a competent driver three and a half hours to finish. And by the time I was done, it was already getting dark. So, little things like lighting and being able to spot addresses, little things like parking. And the first thing that I realized was when you park and you’re in a hurry, the first thing you got to worry about is not getting hit when you get out of the driver side door, especially if you’re double parked. So, that’s why we invented the center drive seat. Well, we didn’t invent it, I should say we’re implementing it.

Ed Bernardon: In combination with your other technology which is unique, right? The combination.

Will Graylin: The combination, yeah. And allows us to open the door on the right side. So, I can park between two parked cars, swing around, find my package, slide open the door, dash between the two cars, and then come back without feeling like I have to avoid traffic and avoid getting hit, getting in and out of my driver’s seat. So, these are little things that we’re doing. And the top hat, you can use it for delivery, you can use it for Uber, you can use it for Lyft, you can use it for a commuter – we have a commuter vehicle that’s coming out as well. So, whether you want to own it, you want to use it as a tool, we believe that the future of mobility are absolutely going to benefit from our robotic wheel invention, which is software and hardware system together.

Ed Bernardon: So, talk about that robotic wheel. When we think of suspensions in a typical car is “Oh, there’s a shock absorber and there’s a spring and it all attaches to the body and all that.” But there are no springs or shock absorbers, this is all done robotically or electrically. So, maybe you could explain a little bit about that, because that is key, I think, to what you’re building this very lightweight vehicle that’s comfortable on.

Will Graylin: So, let me elaborate a little bit more on that. We still use a passive spring that is there to basically balance the vehicle. We call it a passive component. And that passive spring does its job. Our robotic wheel, what it does is it will compress against a spring when we detect that there’s a speed bump. So, then we’ll literally force the wheel and press up against the spring. Now, on the return trip, we can actually regenerate and take some of that energy back from the force of that spring and put some of that back into the system. And then if we detect that there’s a pothole, instead of making the vehicle lean, we push away from the spring. So, we’re still working with the spring, but what is magical about our robotic wheel technology is that we’re using sensors to detect the movement of the vehicle to keep the vehicle stable. Stable whether it is just having rough spots on the road or stable when we’re leaning into a turn. We can control each corner like it’s never been controlled before. So, that means traction control, yaw control, roll control – all of these pieces that allow the vehicle to have either a sports car feel, in fact, active suspension was a whole separate system designed in 1993 by the Williams Formula One team, they used it for racing. But here, we can use it for…

Ed Bernardon: That comfortable ride that keep you always perfectly level.

Will Graylin: Guess what? comfortable rides are super important, especially when you get into autonomous driving. And a lot of people when they get into autonomous driving, there’s a percentage of the population that gets motion sickness, especially when they’re in the backseat and so forth. So, the ability to control the vehicle in such a way that we can make it smooth, and also give you little hints of when you’re about to turn by leaning into a turn, that little sleight hint significantly reduces motion sickness. So, in the world, 5, 10, 15 years from now, when more and more cars are going to be autonomous, utilizing the robotic wheel system is a no brainer.

Ed Bernardon: So, I guess the key is, like you said, active suspensions have been around for quite some time, Williams had them in the ‘90s on Formula One race cars. But the unique thing, it seems, is that the active suspension – the motor is all in the wheel, which then opens up the inside of the car, and it’s adding all these pieces together that make it all possible. So, let’s talk a little bit about your two cahe Alpha and Project Bravo. Why should I buy one once they are available? Which I think is not quite just yet for the everyday consumer. But why would I want one? Sell me an Alpha or a Bravo.

[46:55] Will Graylin: So, I think the reason that you would want to buy one is, number one, how smooth the feeling of being in a robotically wheel-powered vehicle feels like. And once you’ve experienced it, you simply just don’t want to go back – that’s number one. The reason that I am on my fourth Tesla was because I switched from a Model S to a Model 3 when the Model 3 first came out. And I loved the fact that the Model 3 was more efficient and I got the performance model. But when I got into a Model 3, as much as I loved the performance of the car, the ride quality, I was so spoiled by the Model S that after three months, I said, “No. I’m not giving up my comfort from the Model S.”

Ed Bernardon: Yes, you like that smooth ride. Once you’ve had the smooth ride, you can’t go back.

Will Graylin: But I’ll be honest with you, comparing my Model S to the robotic wheel experience going through bumps, it’s no comparison. So, the Indigo-powered vehicle is just so much smoother. So, that’s one major reason why people would want and demand that level of comfort. But here’s the other great things: you can do it for cheaper.

Ed Bernardon: What is the comparison of the operating cost, say, of a Tesla versus one of yours?

Will Graylin: 3.92 cents per mile on my Model S which is much better than 8.4 cents per mile for a gasoline Toyota Camry. That’s still significantly better. But our Bravo comes in at roughly two cents per mile. This is on national average cost of electricity. That’s a significant difference on a per-mile cost-basis. So, there’s a direct correlation between mass, and weight, and the energy that’s used. So, for that reason and for the cost reason, we’re trying to keep the cost of the vehicle as low as possible. The most expensive part is battery. So, if we can use a much smaller battery, like a 30-40 kilowatt hour battery rather than an 80 to 100 kilowatt hour battery, we’re going to save money, we’re going to save the consumer money, we’re going to save the gig economy driver money. And if we can finance it for you, and make it easier for you that to make that decision, you don’t even have to make a buying decision. Just use it for your job. So, this is why we wanted to create a Mobility-as-a-Service, not just selling the vehicles and compete feature on feature. So, let’s start with that. Let’s start with getting vehicles out on the road. Let’s start with you having access to rent it, to try it out with no obligations. And if you don’t like it, return it.

Ed Bernardon: In a way it’s not really a car business. It’s a business to allow people to get into the Mobility-as-a-Service business. That’s at least one aspect of it, it seems. It’s a unique business model in that sense. Lower that barrier of entry.

Will Graylin: New vehicle, it’s a new cost unit economics.

Ed Bernardon: One thing that’s interesting on the Project Alpha is it has only three wheels: two in the front, one in the back. Why three wheels?

Will Graylin: Three wheels further reduces the cost and mass of the vehicle. There are circumstances where we designed the three-wheel Alpha to have the same carrying capacity as a standard Honda Civic. So, in other words, if you’re delivering for Amazon, we made it fit exactly the amount of space that an Amazon Flex does delivery driver with 20 to 40 packages required for them to go do their jobs. And if you’re delivering groceries, that’s even less room that you need. And if you’re delivering for DoorDash and Grubhub for pickup and delivery, that’s even less room. But you still want the comfort and the shelter from the elements, you still want to be able to go highway speeds, you still want that ability to travel to the suburbs and back. So, why not deliver something that is the right size for the right job?

Ed Bernardon: It goes back to your Who/What. If an Amazon driver or grocery delivery driver only needs room for X amount, “Hey, why not three wheels?” If it can make it lighter, which then reduces the cost, so they all play off each other. Now, the Bravo, a little bit bigger, it has four wheels. So, that’s targeting a different market then.

Will Graylin: That’s targeting the ride hail market where there’s passengers or larger cargo space. For some of the deliveries that require larger cargo space, we have 110 cubic feet of cargo space as opposed to 58 cubic feet, which is the average Honda Civic, Toyota Prius type of room. So, that’s the size difference.

Ed Bernardon: A little bit about the performance, top speed, acceleration, those types of things. How do they compare to more conventional vehicles?

Will Graylin: The performance is we make this highway speeds, so you can go 85 miles an hour. The acceleration, depending on the load, but 6-7 seconds from zero to 60, which is still not bad. And if you add passengers, it may take you 8-9 seconds. So, our payload to power ratio, because our overall vehicle, unlike a traditional 4,000 pound vehicle, when you put one, two, or three passenger into the vehicle, it doesn’t matter quite as much to the suspension nor the propulsion. So, for us, we have the propulsion suspension system built-in in such a way that – we’re talking about a 1,600 pound vehicle – when you put one, two, or three passengers in there, you won’t feel the difference in ride quality because of our robotic wheel. We all make the adjustments based on the mass. So, you still have a smooth ride without changing the quality of that vehicle. And when it comes to acceleration, yes, the heavier it is, the slower it’s going to take. But it’s still about the same as most of the vehicles that these gig economy drivers are using anyway.

Ed Bernardon: Well, it seems that only in recent times have we gotten spoiled by electric cars and we start seeing zero to 60 in four seconds, in five seconds, even two and three. Where if you go back 5-10 years, six, seven, eight was pretty much — that’s a good performing car. So, it’s got the zip in there. So, I’m on the highway, I’m on a little tiny three-wheeler going 80 miles an hour – well, I’m going 55, we don’t want to break the speed limit – but I’ve got big semi trucks around me, who knows what. Am I going to be safe in this little teeny three-wheeled car?

Will Graylin: Safety comes in multiple aspects, what we call primary safety and secondary safety, Ed. Addressing primary safety is always number one, which is avoid you getting into the accident in the first place with sensors, with warnings, with detection. The world is already moving in that direction and those things are saving lives, which is great. So, primary sensors and primary safety, not getting into an accident, I think that is priority one, and you can add electronics to help. Avoid it while you can. Safety number two – so, we’re going to be following the same type of FMVSS safety regulatory regulations, especially for the Bravo. For a Bravo, it’s not considered an auto cycle. It’s considered a full-fledged vehicle. So, we have to do all of the crash testing, all of the airbags, all of the safety capabilities that FMVSS requirements force us to – so, the NHTSA requirements and so forth. So, while we do the Bravo, we’re trying to basically leverage the economy of scale of the Bravo to apply it also to Alpha. So, the front half of the vehicle, to make it more cost effective. We’re effectively using the same front half as we are for the Bravo. So, everything that we’re using for the four wheel, we’re going to apply for the three wheel. So, from a safety standpoint, we’re going to apply the same technologies, and we’re going to be using carbon reinforced frames. We’re going to keep it light, but keep it strong, so that if you do get into an accident, that you’re still protected in secondary safety. So, those are the things that we’re doing for maintaining safety.

Ed Bernardon: So, for secondary safety, which would be really where I was driving at with that question, the bigger the vehicle is, the more room you have to absorb all the energy that occurs during a crash. So, as the vehicle get smaller and smaller, especially when like you’re saying where you want to take advantage of the inside of the vehicle as much as you can for packages and passengers You mentioned carbon fiber, are you using special materials? Or is it more in the design of the vehicle and the structure itself, a combination? How is it that you can incorporate a safe, let’s say, vehicle frame and still get all that room that you want on the inside?

Will Graylin: Great question. And that comes into design and innovation. In fact, yesterday, we were talking to one of our partners that does composite. So, for us to leverage lightweight composite for not only reducing mass but also increasing the rigidity and the strength of the vehicle is really important. Remember, we can have a lot of cabin space by freeing up stuff inside. So, your frame needs to be strong. Your safety cell, what we call it, needs to be strong. So, if you can be strong on the outside and you have the airbags on the inside, you can absorb a lot of that impact and translate it. So, when you have a tiny little car that’s made up of the same steel and that doesn’t have room inside, when we can free up more usable cabin space and we see you in the center of that cabin with the central driving seat, we can make that vehicle much safer. So, we believe that the combination of material usage, the design of the vehicle, the intrinsic characteristics of how we make this vehicle safer from wheels that disperse. You can see that a Formula One, the reason that it’s safe when it’s going 250 miles an hour. The reason that it’s safe is not because it’s light, it’s because it can disperse mass, the wheels can come off, it’s got a safety cage that is made out of carbon fiber that’s strong. And those are the same principles that we follow.

Ed Bernardon: You’re utilizing then carbon fiber, at least to some extent. Now, carbon fiber is not the cheapest material in the world. I’m sure the price of Formula One car is way, way more than one of yours. What is the price for your car? Because it seems it’s a very affordable price. Is there anything you did unique in the design for incorporating expensive materials like carbon fiber, say, that allows you to keep that price low?

Will Graylin: Yeah, we’re in fact doing that kind of innovation as we speak; how do we use composite material in the right way? What type of composite material can really use recyclable carbon fiber rather than the new ones that cost four to five times more? Can you also use carbon fiber in smart ways rather than big layups that you have to use vacuum form and autoclave? We’re looking at new technologies that allow carbon fiber. And not just carbon fiber, there’s also things like glass fiber, depending on how you orient the strength of the fiber, that can also be strong. So, the intelligent design of the vehicle is really important to use lightweight composites in a smart way. If you just purely make a carbon fiber using the current methodology of vacuum forming autoclave, it is super expensive.

Ed Bernardon: It’s the right material in the right place, the right amount, and that’s the key to good design with materials like that. So, beyond the Alpha and the Bravo, I think you have some other cars you’re thinking about, maybe one that that I might be able to buy someday. Is that a possibility?

Will Graylin: We’re looking at using the three wheel and the four wheel platforms to have new top hats on top of it. So, the basic structure in keeping the cost, you know, all the design work that we do for the chassis, for the battery systems, HVAC systems, keep all of that the same. And then being able to put something that is fit for the job or fit for the right driver. I may have shown you a picture of our Charlie that we’re currently working towards, which is really a commuter vehicle. For those of us who want to keep something sporty, cool-looking in our garage that we can go out and have fun with.

Ed Bernardon: A sporty commuter vehicle, that’ll be the first one that comes out then you think.

Will Graylin: A sporty commuter vehicle that’s fun, comfortable.

Ed Bernardon: You could take it to the track if you want.

Will Graylin: If you wanted to. And then we’ll have a four wheel version of the same thing for those who want some extra space, extra passenger that they want to carry with them. And they can take that to the track if they want it to.

Ed Bernardon: Just to close out here. Let’s talk a little bit about — Take us a little bit into the future here with some of your plans. What about autonomy? Everyone’s talking about autonomy. Does that play a role in where you think you’ll take Indigo?

Will Graylin: Certainly autonomy will apply to certain types of applications sooner than other types of applications. So, we think that there is room for a lot of different types of autonomy, in the ride hail space, in the delivery space. And they’ll come from different applications in different vehicles. So, for example, I’m invested in a drone company that would deliver pharmacy or fast food that needs to be there in minutes. But that only applies to certain environments where the FAA would allow for that kind of delivery. So, whether you’re talking about someone on their electric bicycle doing fast food delivery, or whether you’re talking about the Grubhub in suburbs, or whether you talk about package deliveries, there are different tools for different jobs. Now, autonomy, we believe the more complex delivery is still going to be human driven for some time, you know, “Hey, I need to actually get this particular heavy package out of my car, and onto your doorstep, and around the back where I’m supposed to drop it off.”

Ed Bernardon: Maybe not for pizza, though, or something simple like that.

Will Graylin: For pizza, I can drop it off on a drone if you want it to. But you have to accommodate for different environments, different neighborhoods. But for people delivery, autonomy is already starting if you’re talking about localized routes, closed-loop circles. But eventually, we believe that autonomy in certain geographies will be very suitable because all you got to do is get your passenger within the block and drop them off versus having to get a package out, delivery to the side door, and take a snapshot that you dropped it off. So, there are different applications. And I think the technology is maturing. And sometimes we always underestimate how much time it takes for technology to catch on. Just like in the payment space [ inaudible] people say, “Oh, NFC, tap and pay, it’s coming. The technology is there.” But it takes years.

Ed Bernardon: “We want it tomorrow.”

Will Graylin: Yeah. And it takes sometimes much longer before you get to the boiling point, in other words, before all the conditions are met for it to adopt. But we also underestimate how fast a technology takes off once all the right conditions are there.

Ed Bernardon: Do you think once autonomy is mature, it’ll play a role in some of the vehicles you put out there?

Will Graylin: There’s absolutely no question in my mind that people want a more smooth, more comfortable ride. It’s not about going zero to 60 in two seconds. It’s about how smooth and how comfortable can I get you there and make you feel that experience. And there’s no better way than cost-effective robotic wheels that Indigo is producing.

Ed Bernardon: One last question about the future. Let’s go 20 years into the future – so, early ‘40s, let’s say – certainly there’ll be autonomy, there’ll be electric vehicles. But I think where you’re a visionary and what you’ve really done with Indigo is you started to say this future world is a mix of scooters, and eBikes, and three-wheeled cars, and four-wheeled cars, and little cars, and big cars. So, let’s use the streets of Boston. We’re down there on Mass Ave, one of the main streets through Boston, what kind of vehicles do you think I’m going to see going up and down Mass Ave in the year 2040? What’s that mix of vehicles?

Will Graylin: I think, in the cities, a lot of the larger vehicles will be kept out and there’ll be micro hubs that will get the kind of deliveries and for the cities, more smaller vehicles will be there, both in terms of parking efficiency, carbon emissions in the city, congestion in the city. Definitely we’ll see that a huge number of them will be autonomous by that point. So, a lot of rideshare when you get into the city. There’ll be a mix of public transportation with private transportation. We think that public transportation and the handoff between me getting into Boston on the red line from Alewife or blue line, the orange lines, they’ll come into hubs.

Will Graylin: And where these public transportation meets, there’ll be charging infrastructure and service stations for you to get into other modes of transportation, whether you want to jump on a little scooter and ride yourself from point A to point B, or whether you want to jump in and use an app to hail either an autonomous or human driven. Most likely by 2040 ridehails will be more autonomous to take me to Logan airport, or take me to my next appointment, or whatever it is. You’ll be using your app quite a bit to hail a ride. You’d be using that same app to maybe tap and pay to get access to that single transportation for you to hop on a scooter. Just same app, I was talking to the city of Boston, the folks over there, they would love to have a key to the city, which is leveraging that same My Mobile Wallet to be able to get on the train, and get on the commuter rail, get on a scooter, or get into Uber or Lyft ride just the same way. And it’ll be smooth, it’ll be comfortable, and it’ll be frictionless.

Ed Bernardon: Will, thank you so much for giving us this vision of the future, and really opening our eyes to what a car can really be. Our transportation will be how it all fits together. Thank you so much for joining us here on The Future Car podcast.

I do want to end in our Future Car podcast tradition with our rapid fire section. I’m going to ask you a series of questions, real quick answers.

Ed Bernardon: If you could have an answer to any question, what would that question be?

Will Graylin: Where is the universe emerging towards? I know that we’re emerging.

Ed Bernardon: We’re going somewhere, right?

Will Graylin: We’re emerging. Emergence and entropy in the laws of physics. And that would be crazy cool to see the universe and where civilization is emerging towards.

Ed Bernardon: If you could give advice to that 12-year-old boy that arrived in Seattle, if you could magically do that, what advice would you give him?

Will Graylin: I would say, have faith in the path that you’re currently on. And don’t stress because the path that you’re on, ultimately leads you to places that you don’t necessarily even expect. Have faith. Keep giving your passion to whatever you’re doing. Whether it’s delivering paper when I was 12 years old, serving as McDonald’s person, or delivering pizza, or joining the Navy. At that time, I still did — You never know where that path takes you, but just have faith that you’re going somewhere where you’re meant to go and put your passion into it and love what you do at the moment.

Ed Bernardon: And be ready to pivot. All right, if you could magically invent one thing, what would it be?

Will Graylin: Magically invent one thing? Something that can solve the gravity issue.

Ed Bernardon: The anti gravity machine. Perfect.

Will Graylin: Understanding how to work with gravity. We still haven’t figured that one out.

Ed Bernardon: And the last question: tell us something about yourself that would surprise your friends and family if they knew it.

Will Graylin: Maybe my friends don’t necessarily know that part of my exercise routine is I do bear crawls at home as part of my routine, lizard crawls or bear crawls. And I would use it sometimes to embarrass my kids when we’re out in public if I ever do a bear crawl, just to embarrass them.

Ed Bernardon: Well, the secret’s out; Will Graylin does the bear crawl. All right, Will, thank you so much for joining us on The Future Car podcast. It was great. Thank you so much.

Will Graylin: Pleasure, Ed. Thank you for having me.

Will Graylin – Guest, Founder & CEO, OV Loop & CEO, Indigo Technologies

Currently Founder and CEO of OV Loop, Inc., a Universal Wallet and Commerce Messaging platform for frictionless commerce experiences everywhere and also CEO of Indigo Technologies, an Electric Mobility company with breakthrough affordable EVs for fleets & drivers. Prior to OV Loop, Will was the Global Co-GM of Samsung Pay, and Founder of LoopPay (acquired by Samsung), ROAM Data (acquired by Ingenico), WAY Systems (acquired by Verifone), and EntitleNet (acquired by BEA Systems/later Oracle). Will holds two Masters from MIT and serves on the Board of Directors for Synchrony Financials (the largest private label credit card issuer in the world) and Global Unites (a non-profit organization to help youths around the world become local leaders through conflict transformation.)

Ed Bernardon, Vice President Strategic Automotive Initiatives – Host

Ed is currently VP Strategic Automotive Initiatives at Siemens Digital Industries Software. Responsibilities include strategic planning and business development in areas of design of autonomous/connected vehicles, lightweight automotive structures and interiors. He is also responsible for Future Car thought leadership which includes hosting the Future Car Podcast and development of cross divisional projects. Previously he was a founding member of VISTAGY that developed light-weight structure and automotive interior design software acquired by Siemens in 2011, he previously directed the Automation and Design Technology Group at MIT Draper Laboratory. Ed holds an M.S. in mechanical engineering from MIT, B.S. in mechanical engineering from Purdue, and MBA from Butler.

If you like this Podcast, you might also like:

- The Next Leap for Electric Vehicles with Will Graylin, Indigo Technologies – Part 1

- Need For Speed – Autonomous Style with Matt Peak, Indy Autonomous Challenge

- Driving the Electric Car Revolution w/ Henrik Fisker of Fisker, Inc.

On the Move: A Siemens Automotive Podcast

The automotive and transportation industries are in the middle of a transformation in how vehicles are designed, made, and sold. Driven by an influx of new technologies, consumer demands, environmental pressures, and a changing workforce in factories and offices, automotive companies are pushing to reinvent fundamental aspects of their businesses. This includes developing more advanced and capable vehicles, identifying new revenue sources, improving customer experiences, and changing the ways in which features and functionality are built into vehicles.

Welcome to On the Move, a podcast from Siemens Digital Industries Software that will dive into the acceleration of mobility innovation amid unprecedented change in the automotive and transportation industries. Join hosts Nand Kochhar, VP of Automotive and Transportation, and Conor Peick, Automotive and Transportation Writer, as they dive into the shifting automotive landscape with expert guests from Siemens and around the industry. Tune in to learn about modern automotive design and engineering challenges, how software and electronics have grown in use and importance, and where the industries might be heading in the future.