Navigating complexities in power delivery analysis: embracing the shift-left approach

The demand for increased power and performance in semiconductor packages has surged. As more die and chiplets are integrated into packages, the challenges surrounding power delivery have escalated. The paradigm of “shift-left” power delivery analysis has emerged as a critical methodology in addressing these complexities. Let’s dive into why.

Analyzing core power requirements to meet IC current demands

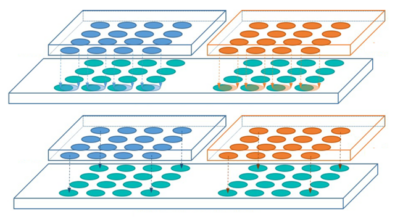

The fundamental challenge lies in comprehensively analyzing core power requirements and ensuring adequate vias and copper provisions for the IC current demands. With the integration of multiple die into high-density heterogeneous packages, the intricacies amplify. Not only does it involve delivering power through multiple rails, but it also entails a surge in complexity due to varied die locations drawing current from these rails.

Moreover, the spatial constraints in such densely packed designs pose a challenge in supplying voltage and current to each die adequately. The scarcity of copper resources further exacerbates this scenario, often necessitating additional layers in the package to cater to the diverse current requirements of multiple chiplets.

The key to success: early problem identification

The key to success lies in predicting design behavior early in the process and making judicious layout trade-offs. The recommended approach involves identifying significant DC-drop problems, which we’ve started calling “big rocks,” at an early stage to enhance final outcomes. This method doesn’t prioritize achieving the utmost accuracy for sign-off purposes but rather focuses on early problem identification to circumvent expensive alterations and project delays.

Beginning with capturing fundamental information about the die or components within the design, the process simplifies complex issues. For instance, assuming an even current distribution across a particular die’s power rail, assigning an average current consumption to each bump streamlines the identification of potential problematic areas. While some bumps might draw more or less current, the aim isn’t perfection but rather the detection of critical issues.

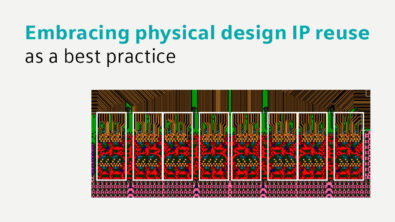

Input current values seamlessly within Xpedition Package Designer

Here is where Xpedition Package Designer (xPD) proves instrumental, enabling designers to input current values for voltage rails seamlessly right within the tool. Leveraging analysis results from HyperLynx, the annotations within xPD facilitate the identification of violations such as excessive current density, overcurrent vias, or significant voltage drops.

The integration of these analyses into the package design environment empowers designers to pinpoint errors without leaving their own tool. Upon encountering an issue, a simple click directs the user to the precise problematic location, enabling swift rectification. This iterative process of identifying, rectifying, and re-analyzing ensures a systematic approach to mitigating power delivery challenges.

Shift left to ensure adherence to project timelines and costs

The significance of the shift-left approach cannot be overstated. By embracing this methodology, semiconductor packaging designers gain a competitive edge in the dynamic landscape of advanced packaging designs. Early identification of potential power delivery bottlenecks allows for informed decision-making and proactive measures, steering clear of downstream issues that could impede project timelines and inflate costs.

The shift-left approach to power delivery analysis stands as a cornerstone in modern semiconductor packaging design. By proactively identifying and mitigating “big rock” problems early on, designers can navigate the complexities of high-density advanced packaging designs more effectively, ensuring efficient power delivery and optimal performance of integrated chiplets. This strategic approach not only saves time and resources but also fosters innovation by enabling designers to focus on pushing the boundaries of semiconductor technology.

Read more about this concept in our eBook: IC Package physical design best practices