HORIBA MIRA: A fast driver towards improved electric car sound development

If you were asked to name one benefit of electric cars, what would you mention? Well, many people appreciate the low electric car sound. It’s true, the electrified powertrains operate on much lower sound levels, which makes these vehicles relatively quiet compare to the ICE (internal combustion engine) vehicles. But there’s a big but.

Given the fact that the loud internal combustion engine is removed, electrified vehicles lose the largest noise source. This means that the other sounds like – wind, road and ancillary system noise become more audible, and believe me, these sounds are not very pleasing for human ears. At least, it’s nothing you want to be bothered while driving your new car. And this is the new challenge for the NVH development teams. What’s more, these teams need to work around the clock to develop new model faster than the competition. So, the new challenge and time pressure pushes the automotive OEMs and suppliers to reshape the established development process and adopt new development technologies.

HORIBA MIRA

HORIBA MIRA is one of the examples of companies pioneering the electric car sound development advancements. As automotive supplier, HORIBA MIRA offers proving grounds, test facilities and engineering consultancy services to component suppliers and well-known automotive brands.

“The great value we add is to understand and define the targets that our customers and end-users require, then devise technical solutions that deliver those attribute requirements.”

Nick Fell,Engineering and Technology Director HORIBA MIRA

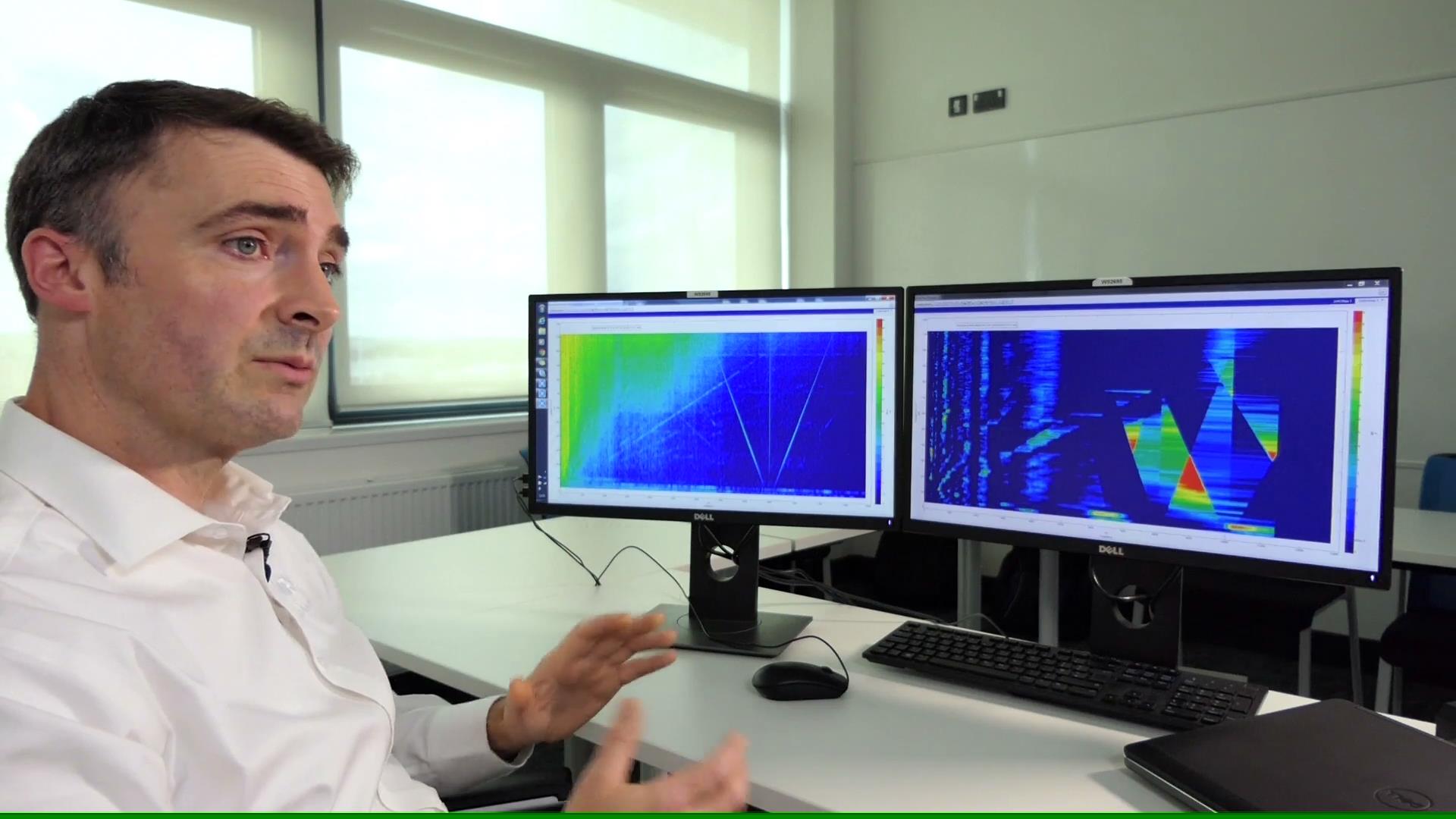

To facilitate their customers in the electric car sound refinement, and to provide essential engineering insights, HORIBA MIRA uses transfer path analysis (TPA) as one of the fundamental techniques.

Transfer path analysis to master electric car sound

This engineering approach is based on interior noise and vibration measurements that are consequently broken down into contributory paths. During the testing campaign, a fully instrumented vehicle with microphones and vibration sensors measure the frequency response of the structure at various driving speeds. As and outcome, the final analysis can identify the exact root-cause of the noise issue and its route.

“It is important to understand the exact route because we can then make design recommendations to our customer if necessary.”

Mark Randle, NVH Team Leader at HORIBA MIRA

HORIBA MIRA relies more than 25 years on the Siemens Simcenter testing solutions including Simcenter Testlab software and Simcenter SCADAS hardware.

“The capability it gives enables us to be more efficient, from design through simulation to validation. With our license model, we have access to a rich and wide range of methods, both for acquisition as well as processing of the data. This allows us to select the best methods for different needs.”

Mark Randle, NVH Team Leader at HORIBA MIRA

How does transfer path analysis work and how it can provide essential insights to the interior sound quality refinements? Read the full article and learn how HORIBA MIRA achieves high efficiency in the NVH measurements.