Simcenter STAR-CCM+ 2020.3 released! What’s new?

With Simcenter STAR-CCM+ 2020.3 Siemens Digital Industries Software provides increased simulation realism, enabling you to accurately model the complexity of today’s products and deliver real innovation.

Join our live product release event of Simcenter STAR-CCM+ 2020.3 on November 5th, Live on LinkedIn

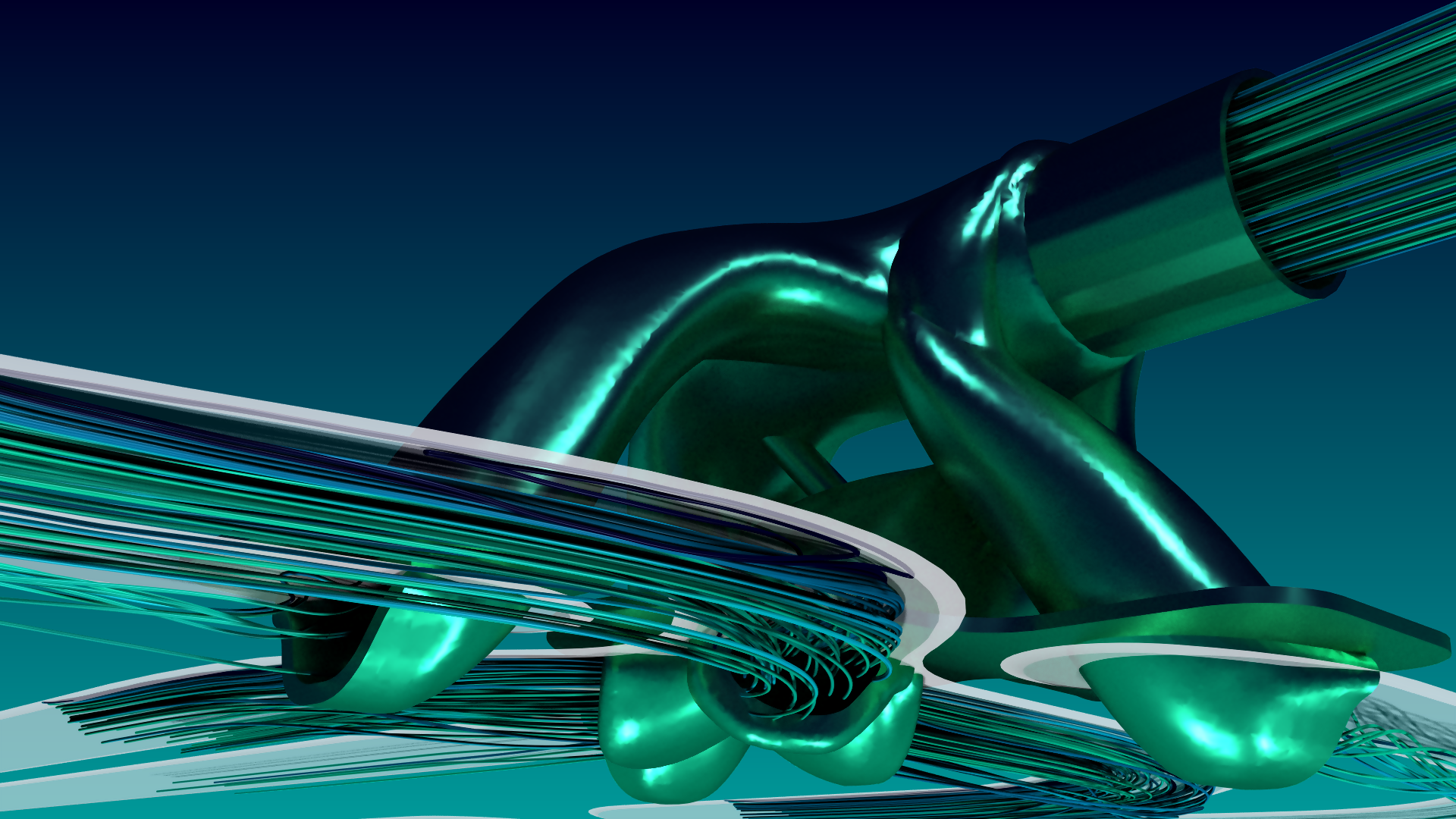

Find optimal designs using topology optimization

Adjoint-based flow topology optimization is an exciting new way to quickly find ideal designs. With an inbuilt constrained optimization method and an end-to-end workflow, you can now leverage this cutting-edge technology. This allows you to generate highly efficient, and often non-intuitive solutions to your design challenges.

Learn how to find better designs using flow-based topology optimization

Improve accuracy of process simulations coupling CFD and gPROMS

Improving chemical processes like spray-drying or mixing requires accurate modeling of complex physics and chemistry. gPROMS is a powerful modeling environment to simulate such processes. You can now easily use CFD simulations from Simcenter STAR-CCM+ 2020.3 to calibrate a multizonal gPROMS model. This improves modeling accuracy and eliminates uncertainty.

Read more about leveraging multiscale simulation in the process industry

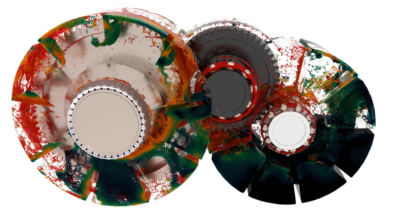

Reduce computational cost for hybrid multiphase modeling

With version 2020.3 we’ve introduced an exciting new hybrid multiphase capability. This enables you to more efficiently simulate liquid flows in applications where flow breakup is present, such as vehicle water management or spray cooling. The VOF to Lagrangian transition model resolves the formation of droplets using a Volume of Fluid approach. To track these droplets, the model automatically switches to a Lagrangian method, significantly reducing computational expense and simulation turnaround time.

Design better engine combustion systems with liquid film modeling

High fuel loading in Internal Combustion Engines may cause undesired liquid films to form on surfaces. With version 2020.3 you can now model this phenomenon with Simcenter STAR-CCM+ In-Cylinder Solution. This means better understanding of the performance impacts of high fuel loading, including emissions and pool fires, and leads to better combustion system design.

Learn how to run more realistic combustion engine in-cylinder simulations with liquid film modeling

Speed up simulations of free surface flows with droplets or bubbles

Simcenter STAR-CCM+ 2020.3 also introduces the mixture multiphase large-scale interface model: a new approach to simulate free-surface flows with droplets or bubbles for applications like gear lubrication. This approach removes the need to resolve all relevant scales in the mesh, bringing faster and more accurate answers.

Learn how to speed up your free-surface flow simulations with MMP-LSI

Improve accuracy of unsteady RANS simulations at no additional cost

Finally, the new scale-resolving hybrid turbulence model helps capture more small-scale turbulent structures in an unsteady RANS simulation. This means, for example, increased fidelity of your transient aerodynamics simulations without additional computational cost.

Find out more about scale-resolving hybrid turbulence modeling

Join our live product release event of Simcenter STAR-CCM+ 2020.3 on November 5th, Live on LinkedIn

Comments

Comments are closed.

Hello,

unfortunately I can’t design a co-simulation in 2020.3 like I did in 2020.2. I found out that the “Co-Simulation” tree is renamed to “External Links”. However, when I create a “Simcenter Amesim Link” in 2020.3. I can only create models and zones. In 2020.2 I could also create conditions and values in this tree, which is necessary for co-simulation. How can I do this in 2020.3?

Thank you very much!

With kind regards

Michael