Efficiency through simulation for high temperature processes

Humans have used fire for thousands of years. From cooking meat to make it easier to eat and digest, to firing pottery to make watertight containers, to managing grass or moorlands through controlled burning. Throughout history, high temperature processes have been a vital tool for many aspects of human existence.

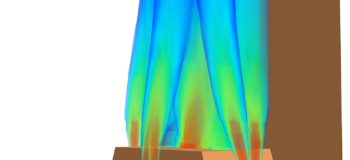

Today, combustion is an essential part of industrial processes. Coal burners, dryers and kilns, and steel furnaces are just some of the areas where combustion is important.

But how can you ensure that these high temperature processes are as efficient as possible? Inefficient processes lead to costly and excessive energy consumption, with the potential of excess emissions and non-optimal product yields.

Computational Fluid Dynamics (CFD) is now an established tool for virtually investigating many complex process problems. But are you using it to its full potential?

This on-demand webinar takes a look at recent advances in simulation capabilities in Simcenter STAR-CCM+, which make simulation and optimization of combustion processes even easier. Our technical experts cover:

- Recent advances in CAD maneuverability for geometry setup

- Different reaction modeling approaches available in Simcenter STAR-CCM+

- Combining CFD and design space optimization for intelligent geometry optimization

Successful use of simulation is enabling process engineers to reduce design costs and create innovative, efficient designs. Discover how CFD can help to optimize your high temperature processes.