Poorly designed pumps use 10% of world energy

Let’s play a game.

Count up all the pumps in your life: the pumps that operate your home HVAC system; oil pumps, water pumps, fuel pumps and aircon pumps in your car; the pump inside your expensive frothy coffee machine; the pump that provides pressure to your electric shower.

It should be immediately obvious that each of us depends on multiple pumps in our everyday life, and for that to be the case, that there are many more pumps than people in the world (without including all of the thousands of industrial pumps used in power generation, waste disposal, and manufacturing).

It should be immediately obvious that each of us depends on multiple pumps in our everyday life, and for that to be the case, that there are many more pumps than people in the world (without including all of the thousands of industrial pumps used in power generation, waste disposal, and manufacturing).

By some estimates, pumps account for over 10% of world energy consumption. [1],[2],[3].That’s more than 2 TW-year of energy, just for pumps, more than the total of renewable power generation in the whole world.

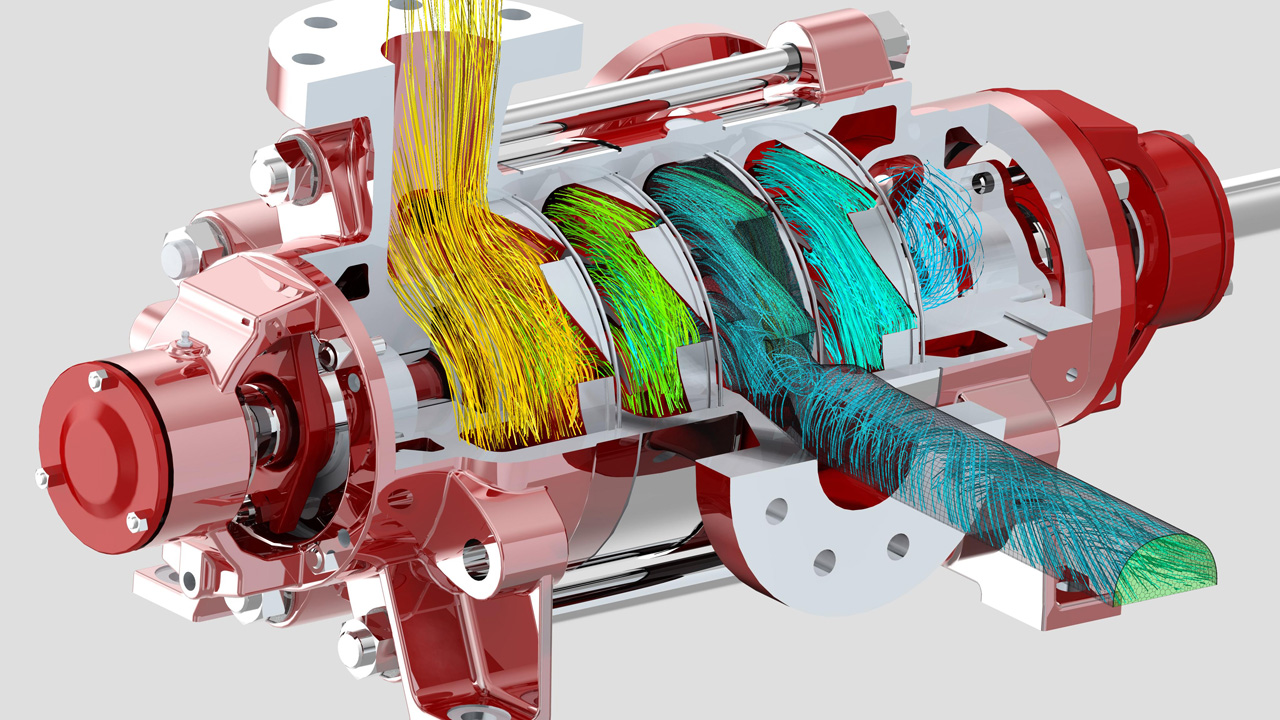

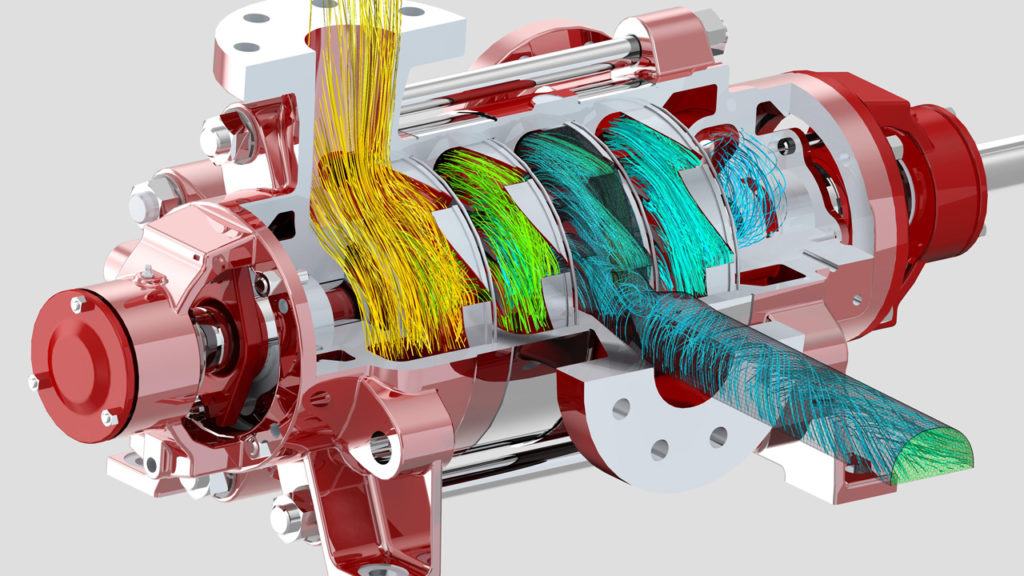

The vast majority of those pumps are poorly designed and inefficient. Traditionally, pumps have been treated as “off the shelf” items that are chosen to match the specific operating conditions under which a device is expected to perform. They rarely undergo detailed design analysis, as an isolated component or as part of a finely tuned system.

This causes all sorts of problems; firstly systems rarely operate under the single design condition under which the pump was specced. Secondly, the usage of equipment often evolves during its operational lifetime, such that it will be expected to perform significantly outside of design conditions.

At a time when the whole planet is headed towards climate change catastrophe, and world governments flail around helplessly trying to reduce energy consumption, even a small increases in pump efficiency will have considerable consequences in terms of the energy performance of individual products, and the industry as a whole.

Mechanical Solutions Inc. (MSI), headquartered in Whippany, New Jersey, specializes in fluid machinery design, fluid dynamic analysis and mechanical design and analysis. MSI focuses on the analysis, testing and troubleshooting of all kinds of rotating, reciprocating and turbomachinery, using sophisticated analysis and testing tools. Find out how MSI managed to revolutionize their pump design process using Simcenter STAR-CCM+ CFD simulations, by downloading this white paper.

Find out more about using Computational Fluid Dynamics to design more energy efficient and robust pumps, by watching this on-demand webinar recording.

Comments

Comments are closed.

This is true. That’s why it is important to invest in quality electric fuel pumps. That’s why I bought this electric fuel pump wide, to avoid frequently changing this and, in turn, helping the environment.