Toyota Corolla: perspectives for the world’s most popular car (Part 2)

Few weeks ago, we went through technological evolutions that led to the success of the Toyota Corolla.

In this follow-up post, we propose to switch from a retrospective to a prospective usage of Simcenter Amesim by exploring what could be the technological future of the world’s best seller Toyota.

We will compare the following powertrain technologies with the conventional eleventh generation of the Toyota Corolla:

Let’s start with the hybrid powertrain analysis.

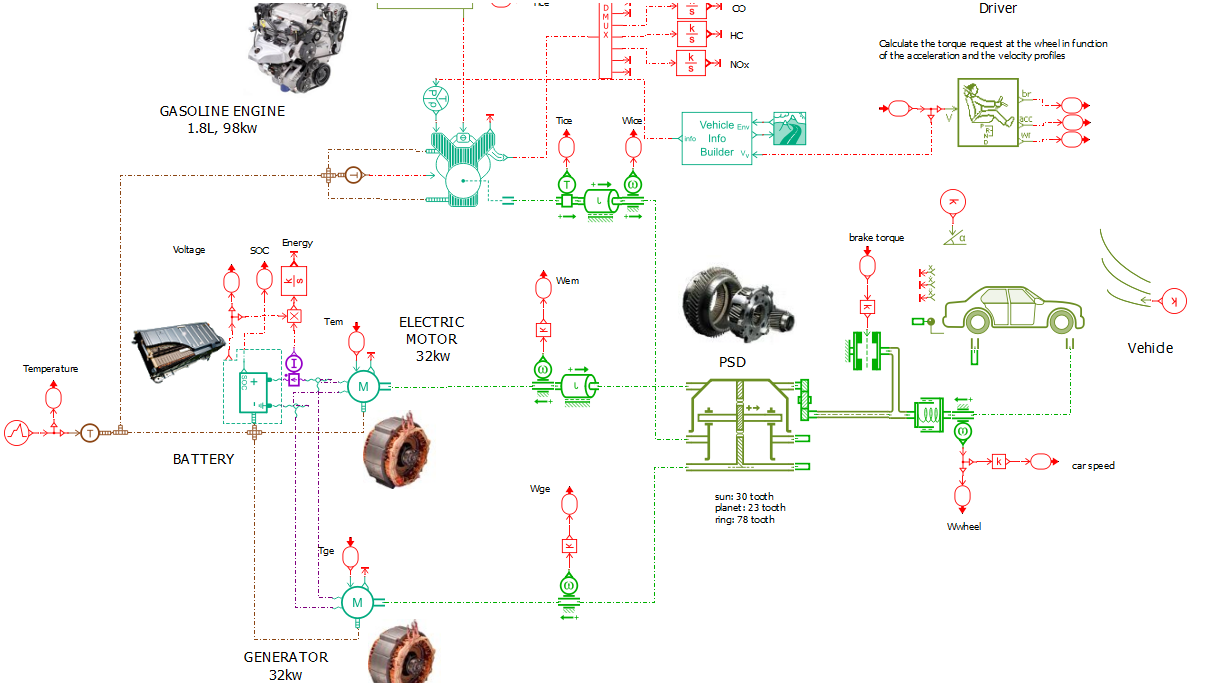

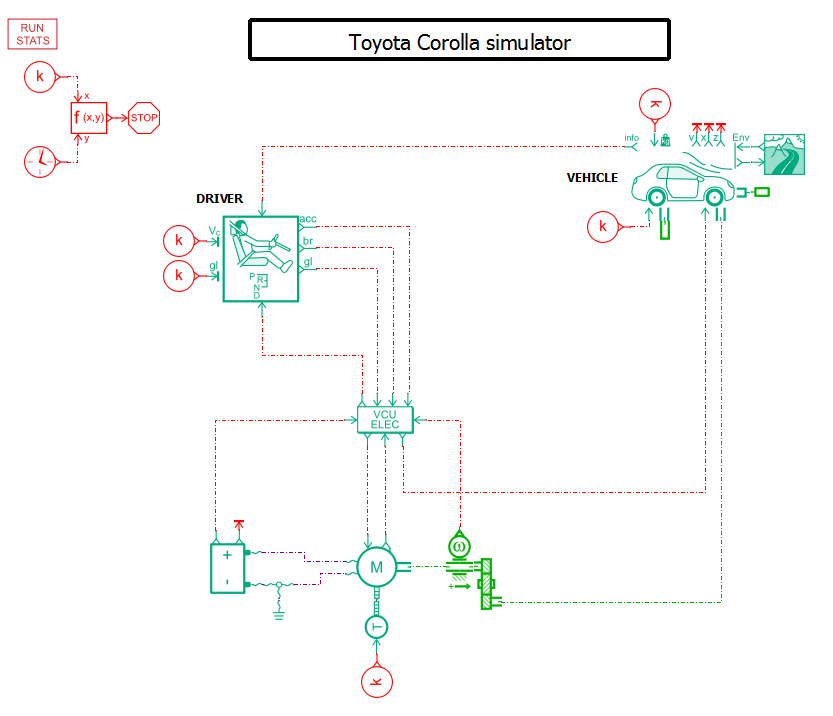

Simcenter Amesim model of the Toyota Corolla with Hybrid Synergy Drive powertrain

Simcenter Amesim model of the Toyota Corolla with Hybrid Synergy Drive powertrain

The parameters are found on the web for the 3rd generation of the HSD powertrain and the 2ZR-FE engine maps are generated using the engine tables creator.

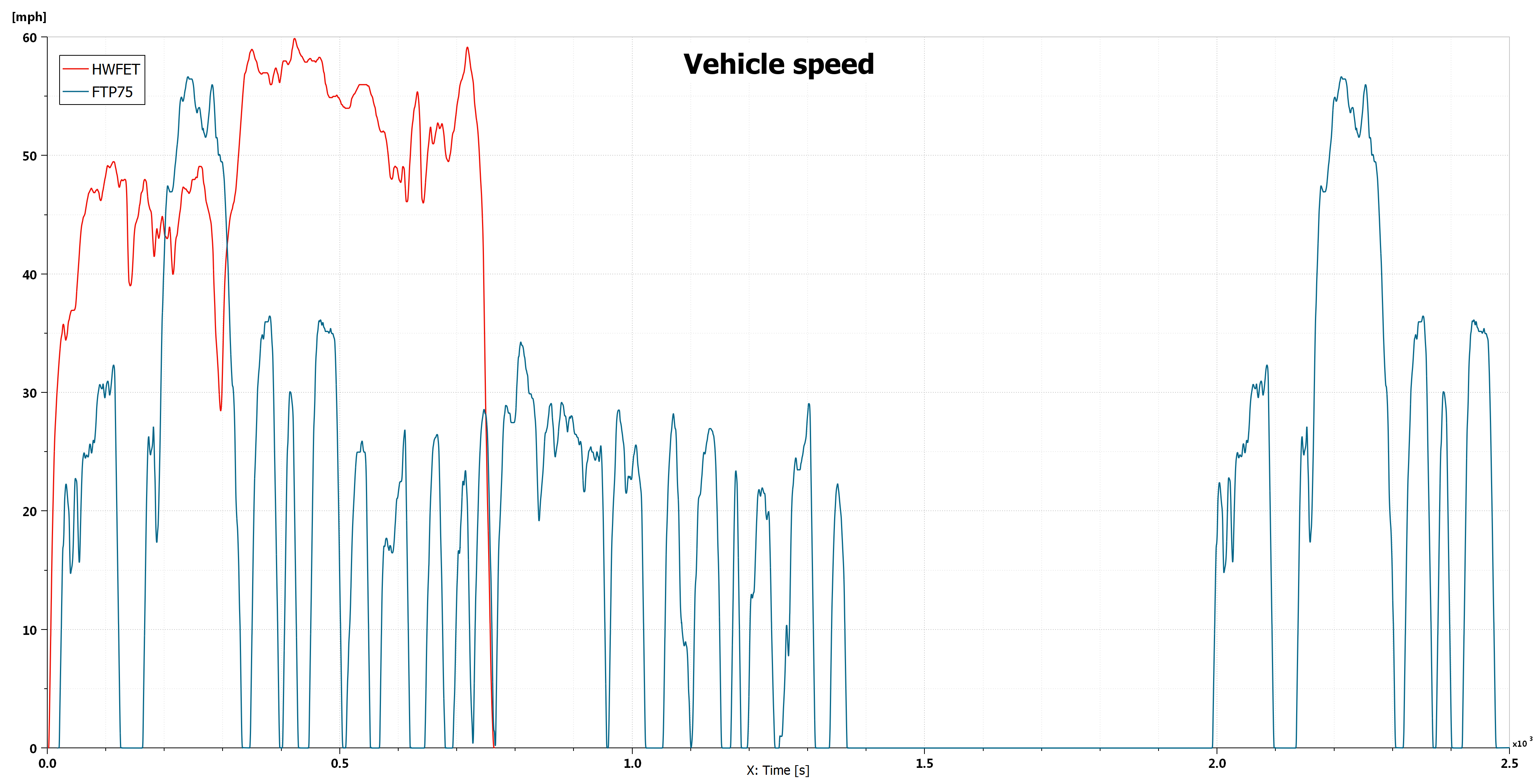

The driving cycles chosen for the comparison with conventional Corolla are the same as in the previous post:

- FTP75

- HWFET

- Top speed

Driving cycles

Driving cycles

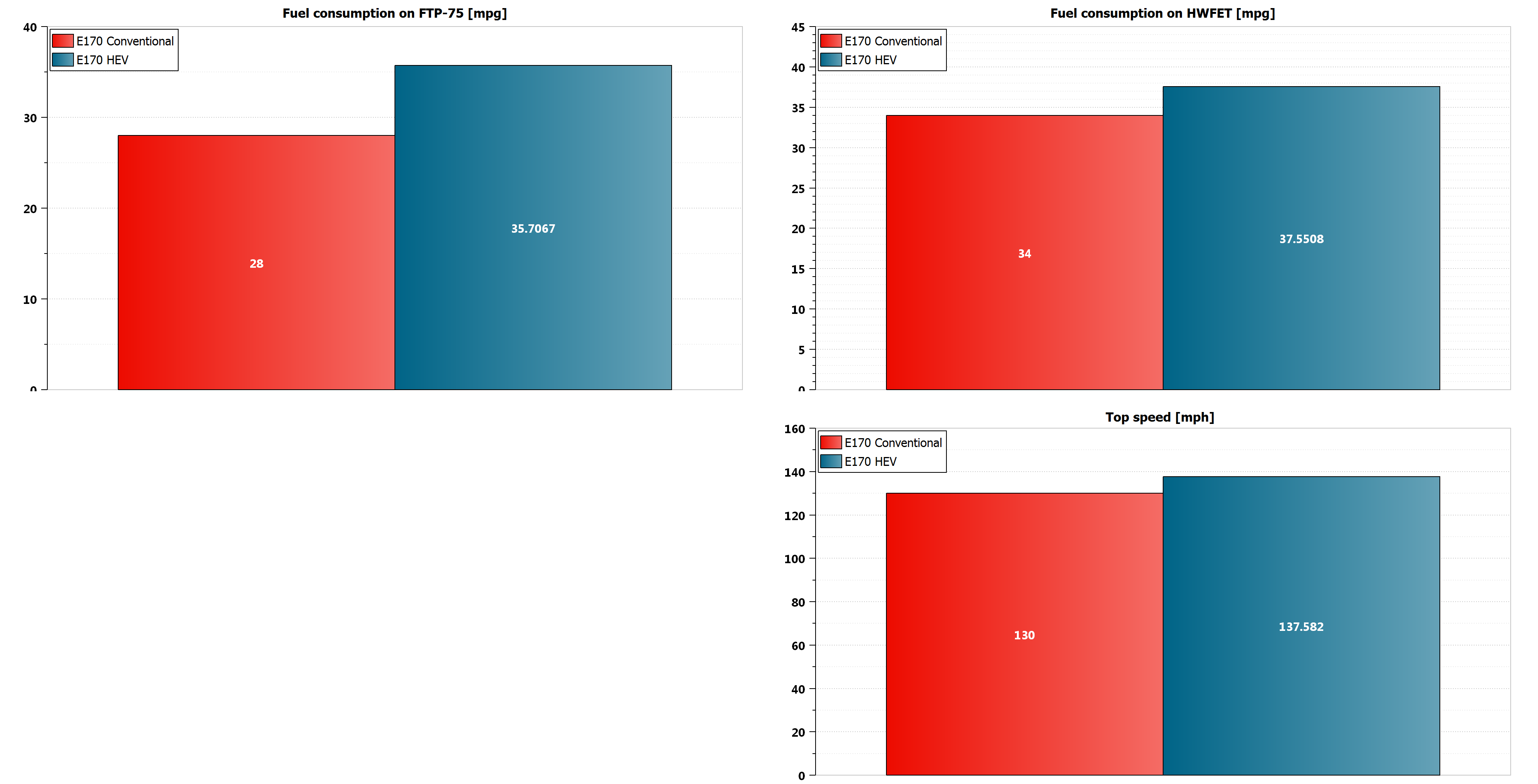

Simulation results are shown below: Toyota Corolla E170 HEV and conventional powertrains comparison

Toyota Corolla E170 HEV and conventional powertrains comparison

It is clear that the benefit of the hybrid electric vehicle (HEV) powertrain is higher on the FTP75 cycle as it contains more accelerations and decelerations (urban profile), meaning more kinetic energy to recover.

The 2019 Toyota Corolla will come with the 4th version of the HSD powertrain and EPA fuel consumption figures will probably be much better that the ones showed here.

Next step of electrification would probably be a battery electric Toyota Corolla. It is particularly relevant as Toyota announced a partnership with Mazda and established a dedicated Electric Vehicle division.

The Simcenter Amesim model is depicted below: BEV model

BEV model

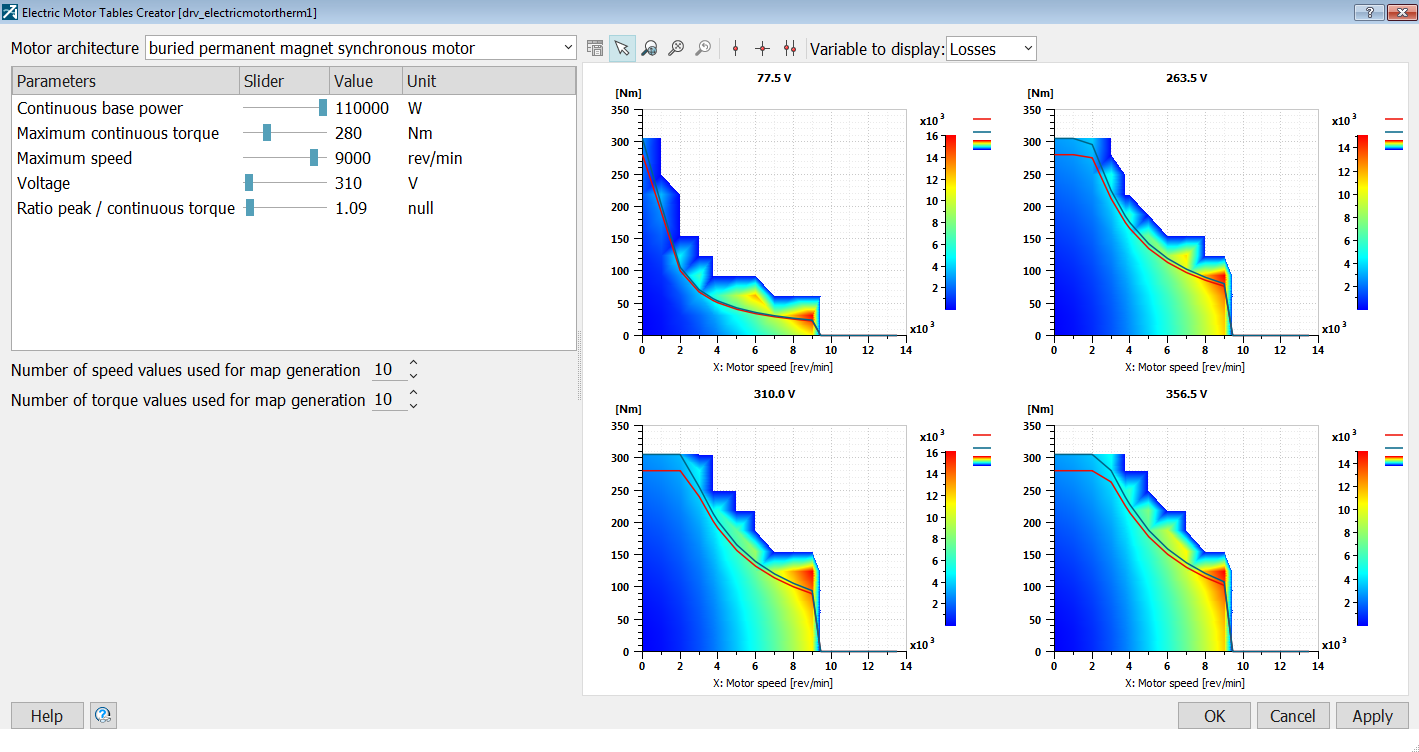

Again, as for the previous models, the modeling approach is the simplest one (quasi-static models, no thermal management). The model is taken from the standard Simcenter Amesim demo models. The electric powertrain parameters are considered arbitrarily as below:

- Battery: 300 V, 160 Ah

- Electric machine: 300 V, 110 kW, 280 Nm, 9000 rpm max

- Transmission: single speed with ratio of 5

The electric machine parameters have been generated using the Electric Motor Tables Creator: Simcenter Amesim electric motor tables creator

Simcenter Amesim electric motor tables creator

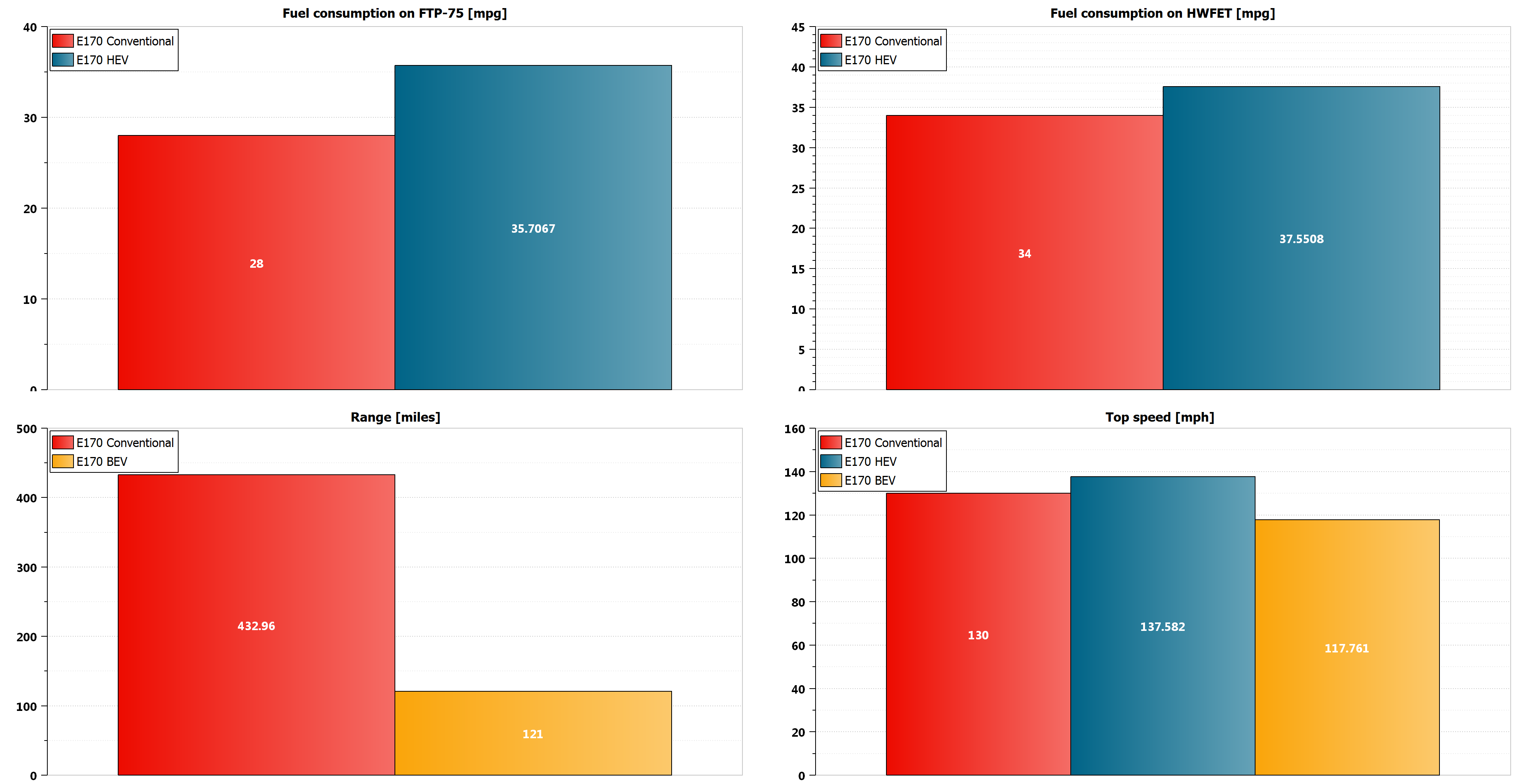

The simulation results are compared with the conventional and HEV powertrains results:

Comparison BEV-HEV-Conventional

Comparison BEV-HEV-Conventional

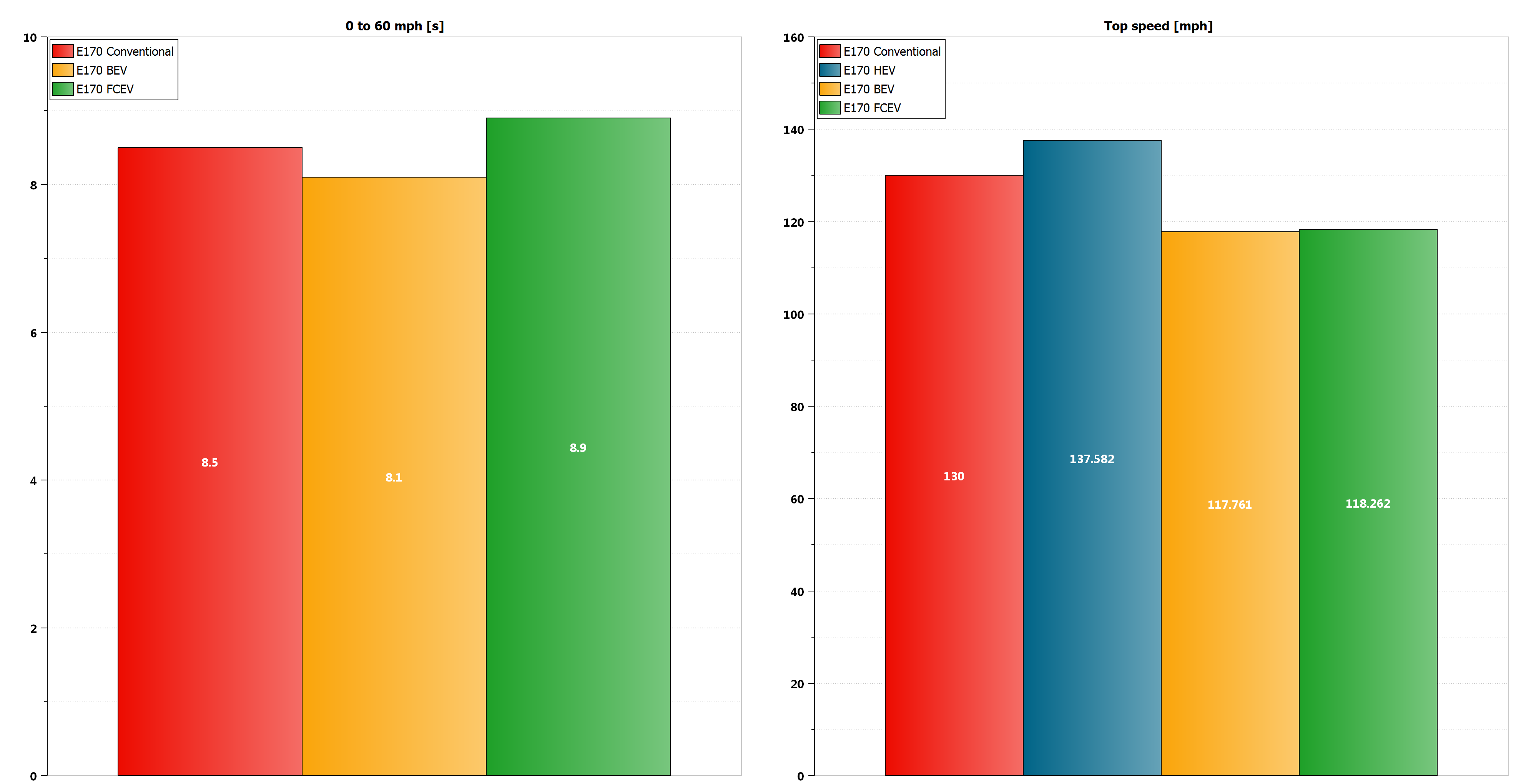

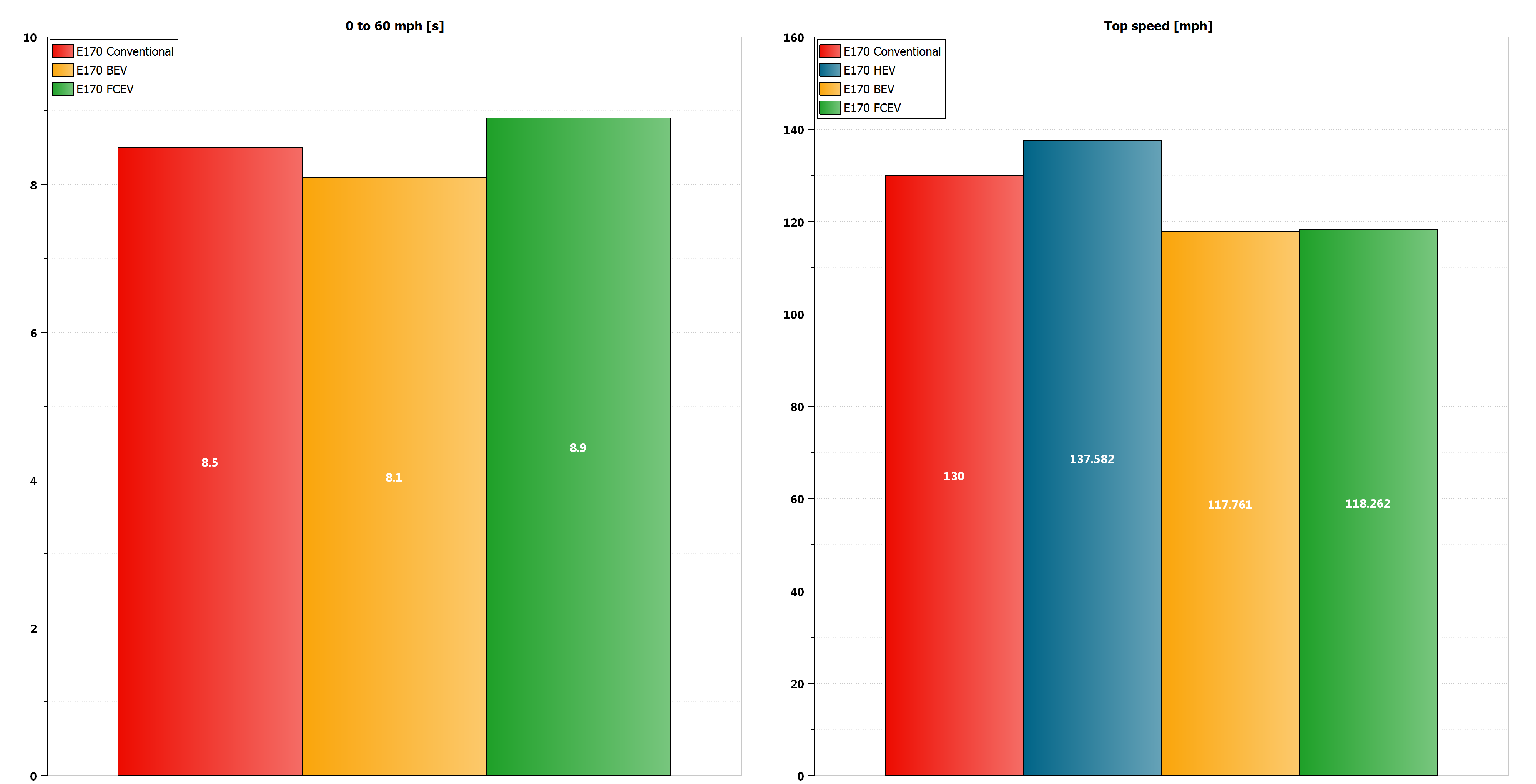

Of course, fuel consumption is not relevant anymore, but it is interesting to compare the range on HWFET cycle and top speed which are clearly not in favor of the electric vehicle. To make the comparison a bit fairer, we should consider local emissions impact, cost of ownership and complete life cycle assessment, and that could be the topic of a dedicated post.

A more detailed analysis of a battery electric vehicle is presented in this on-demand webinar: Evaluate your electric vehicle architecture to reach the best trade-off between performance, range and comfort.

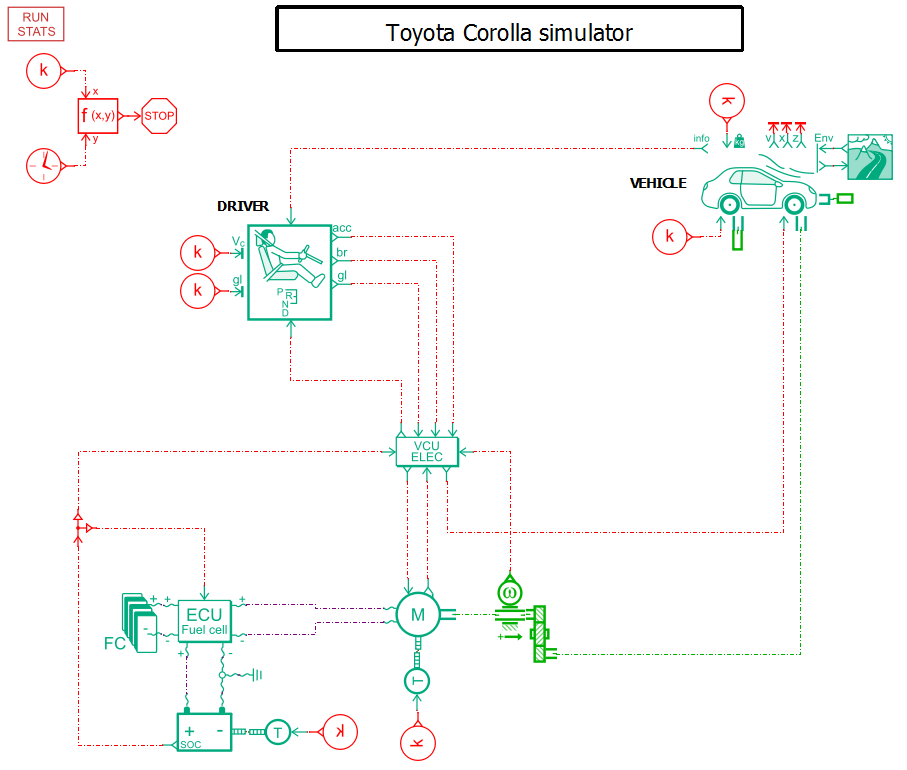

Finally, we considered a fuel cell electric variant of the Toyota Corolla (similar to the Mirai): Simcenter Amesim Fuel Cell electric Corolla version

Simcenter Amesim Fuel Cell electric Corolla version

This model is also carried-over from the demo models portal. The vehicle, electric motor, gear ratio and driving cycle are the same as for the previous configurations. The fuel cell data are set to default values:

- H2 fuel

- Curve of voltage as a function of current

- Curve of fuel consumption as a function of current

The results are compared below: FCEV-BEV-conventional Toyota Corolla performances comparison

FCEV-BEV-conventional Toyota Corolla performances comparison

Note that we didn’t take the time to compare all the architectures in terms of range.

To conclude, we presented how to quickly compare several powertrain architectures without the need of many data and starting from ready-to-use template models. This enables to make early engineering decisions based on trends for attributes of interest.

Alternatively, the Hybrid Optimization Tool could have been used. For you to run a similar analysis, which modeling method would you use? Starting from demo models, using the Hybrid Optimization Tool or building your own models from scratch? Just let us know by posting a comment below!