MIMO control: paving the way to more realistic testing

Vibration qualification testing has been carried out since the 60’s of the 20th century to verify that performance and safety of products are not compromised and guarantee product survivability in real-world environmental conditions. Many products have been qualified through single shaker vibration control testing to ensure their survival through launching, operating or transportation environmental conditions.

However, the ability of this testing approach to replicate any real-life vibrational environment has been questioned by the dynamic environmental testing community for some time which has sparked interest in more realistic testing methods based on multi-axis testing.

Let’s compare both testing procedures and understand the drive for innovation.

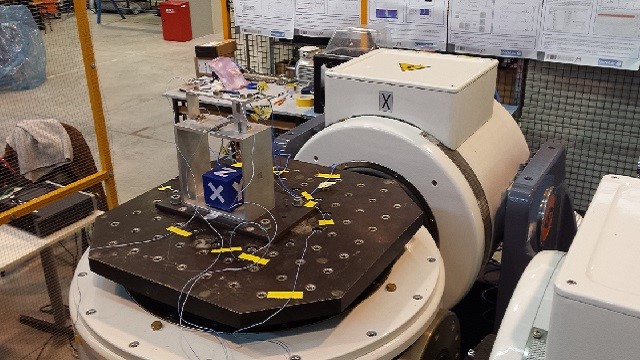

Multi-axis shaker at the University of Ferrara

Limitations Single Axis Vibration Testing

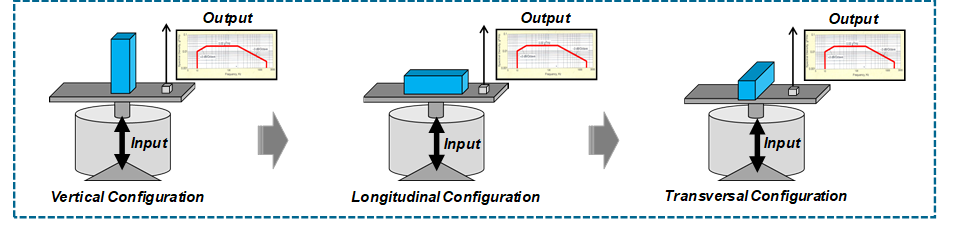

Traditionally, vibration testing has required single axis systems, using a linear vibration shaking system and testing in one direction, then rotating the sample until all three axes (X, Y, Z) have been tested, as real world vibration environments are characterized by multi-axis motions.

This practice has however some technical and practical limitations.

- The time-to-failure ratio is grossly overestimated. Sometimes, test teams also witness different failure modes than the ones observed in real operation condition.

- Sequential single-axis testing doesn’t take into account the interaction between the main excitation sources and paths. Moreover, it ignores the effect of the combined loading on the various stress/strain states and dynamic behavior of the structure.

- When time is a constraint or when the availability of the test specimen is limited, the long time needed to physically change the orientation of the test article and instrument it to test each axis may also affect the overall duration of the test campaign

- Moreover, when the test item is one-of-a-kind, which is often the case with satellites, for example, there is a risk of damage during the maneuvers required to change the test setup.

This is where multi-axis and more generally multi-input multi-output (MIMO) vibration control testing comes in, to achieve more reliable and test-efficient test procedures.

Advantages Multi-Axis Vibration Testing

Today, due to the readiness of standards, (e.g., Mil STD 810G, Method 527 and IEST DTE 022 working group recommendation) for MIMO Testing, the increased availability of multiple shaker testing systems and the development of advanced MIMO control strategies multi-axis vibration testing is becoming standard not only in the defense industry, but also space, automotive and other commercial industries as well.

One of the main benefits of multi-axis vibration testing is that it allows companies to obtain results from several individual tests combined in a single test, significantly reducing the time required to test and verify products. In addition, the vibrational excitation of a structure in real operational conditions is typically multi-directional. making MIMO control strategies the most accurate way to replicate real operational environments of an item’s entire life cycle.

These advantages, in addition to their engineering value, can ultimately result in cost savings in the field of testing and validation of the designs during product development.

State-of-the-art control strategies

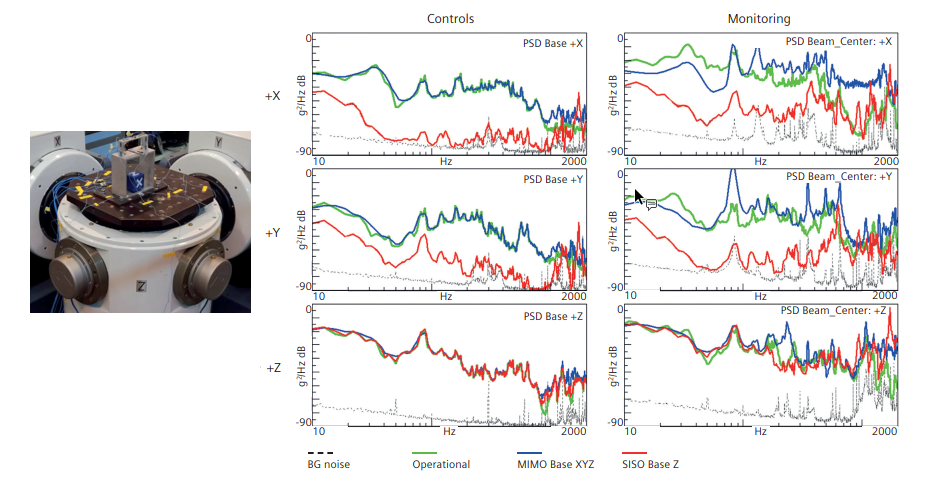

Siemens Digital Industries, leader in vibration control and acquisition systems has worked together with industries and universities to develop, test and optimize MIMO control strategies that enable MIMO type of testing and improve the in-service environment replication.

Watch next video testimonial about multi-axis vibration testing using Simcenter Testing at University of Ferrara

Read more details about these control strategies in this white paper and learn how MIMO control technologies such as MIMO random control and TWR can be implemented to increase flexibility, reduce testing time and avoid over-or under-testing.