Simcenter STAR-CCM+ 2021.2 Released! What’s new?

Spaceflight is facing a massive revival, hypersonic flights are about to experience a renaissance in civil aviation, more down to earth applications like home appliances need to continue to get more eco-friendly, medical devices like heart valves have the potential to save the life of millions and the everlasting engineering challenge of getting the heat out of all things hot remains a billion-dollar challenge across all industries.

And while all these applications have the potential to change human lives for the better they come along with an ever-increasing engineering complexity.

The key to cope with this complexity is the uncompromising implementation of a digital twin and simulation technology. And yet simulation can only bring value if it models that complexity and if at the same time engineers can do simulations quickly enough to influence design. Hence, to keep the competitive edge, companies need to equip their simulation engineers with CFD software that delivers high-fidelity physics models, smart simulation techniques and fast meshing technologies.

With this mission in mind, Simcenter STAR-CCM+ 2021.2 delivers new features across the entire simulation workflow to help you engineer innovative and better performing products, faster – from hyper-sonic spacecrafts to life-saving heart-valves.

To download Simcenter STAR-CCM+ 2021.2, please visit the Support Center

Higher accuracy for hypersonic applications

Hypersonic vehicle design requires accurate prediction of bow shocks and surface heating, a challenge for CFD codes due to the carbuncle effect. Improvements in Simcenter STAR-CCM+ 2021.2 mitigate this effect to deliver better convergence and realistic temperature predictions, giving you higher confidence in your simulation results.

Learn more about hypersonic simulations in Simcenter STAR-CCM+

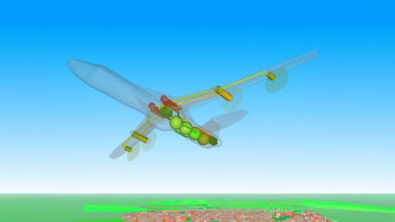

Faster industrial multiphase simulations

Accuracy and computational efficiency are often competing goals for multiphase simulations. With our hybrid multiphase approach, coupled with adaptive mesh refinement, you don’t have to compromise on either. In Simcenter STAR-CCM+ 2021.2, this modeling approach is expanded to include simulations with fluid film. Now you can get fast, accurate predictions for a broad range of multiphase applications ranging from electric machine cooling to home appliances like dishwashers.

Explore how to unlock the potential of hybrid multiphase simulations leveraging AMR

Increased productivity for thermal management

Modeling the thermal response of products with many thin structures can be challenging due to the labor intensive set up of the simulation. To enable accurate, yet efficient conjugate heat transfer analysis for such configurations, Simcenter STAR-CCM+ 2021.2 introduces the new part-based shells capability. This approach allows you to easily automate your simulation pipeline and create template sim files for applications such as vehicle thermal management and oven curing of painted parts.

Find out more about how to increase your productivity with part-based shells

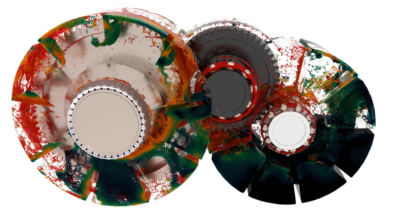

Reduced turnaround time for periodic cyclic motion

The general remeshing solver allows you to easily simulate moving bodies through morphing and remeshing. Version 2021.2 brings improvements specific to periodic cyclic motions, such as gear pumps, by automatically storing and re-using the mesh, reducing the overall solution time.

More efficient transient fluid-structure interaction simulations

Most fluid-structure interaction (FSI) phenomena are transient in nature with many industrial applications having physical time scales that change throughout the operating cycle. Examples are opening and closing valves, or applications involving an impact, where time scales can change by several orders of magnitude. With the Adaptive Time Step Model, you can configure your simulation such the time step size is optimal throughout the entire simulation, small when needed, but large whenever possible. This drastically improves the turnaround time and robustness of the FSI analysis.

Read more on FSI and learn from highly-fidelity heart-valve simualtions in Simcenter STAR-CCM+

Faster meshing for bulk geometries when using the thin mesher

Many real-life geometries consist of a mix of parts which are thin and others which are bulky. To ensure efficiency when solving, the thin meshing technology in Simcenter STAR-CCM+ automatically meshes the thin areas with prisms and uses standard, isotropic cells elsewhere. This release enables up to 3.7x faster meshing by parallelizing the mesh generation of bulk parts when using the thin mesher, resulting in a faster simulation throughput.

More meshing speed-up technology? Check out about AMR and parallel polyhedral meshing

Crowd-sourcing innovation for outstanding CFD software

Also, along with the release comes the launch of the new Ideas platform allowing Simcenter STAR-CCM+ users around the globe to help shape the future direction of the software. “Ideas” allows you to suggest, vote, and comment on ideas to improve Simcenter STAR-CCM+. And while this concept of democratizing the software development process is not new to Simcenter STAR-CCM+, the new platform will enable even better communication between our customers and product management teams and a more efficient way of prioritizing ideas. This will ensure a continuous stream of new features and enhancements that match your demands and enable you to achieve your engineering goals.

Find out more about the new home for your ideas and submit them today to improve Simcenter STAR-CCM+