The Art of Engineering through Design Exploration

In 2017 my house turned 100 years old. Over the course of that 100 years it has had a relatively interesting life. Constructed in the lush, forested, Pacific Northwest at the turn of the 20th century it was originally inteded to serve as part of an on-site employee housing camp for a commercial logging company. As logging progressed over several decades, and the areas of operation shifted from one location to another it became inefficient for the logging companies to provide employee housing and they made the decision to divest themselves of these housing camps. Located in somewhat obscure areas with little appeal to a general population they priced the homes very low but stipulated that they must be relocated by the purchasers. Intrigued by the opportunity this presented, a local entrepreneur purchased a large track of land in a nearby city, subdivided it, and arranged all of the logistics that accompany relocating a home 4-5 miles and across a major river. Since being relocated in the 1950’s my home has had several major renovations including an addition and subsequently being raised to provide an additional floor at ground level.

Recently we have been adding our own chapter to the history of this home by doing a complete renovation of the master bathroom. During this project I have found myself fascinated by the way different techniques, materials, and technologies were melded together over the last century. During the demolition we took everything back to the studs. Each layer that we removed was like a mile marker for the time period in which the work was done. We discovered multiple layers of wall and flooring of all different types. Though much has remained the same there have been many innovations and changes that have come in 100 years. Electrical and plumbing have progressed to be safer and more reliable, finishing materials are cheaper, faster, and easier to put up. Valves have become more sophisticated with technology for better maintaining constant water temperature, high efficiency heating can be installed under tile flooring, etc… Having removed everything and looking on the original structure of the 100 year home I was somewhat fascinated by the concept of strong, high quality timber as the foundation upon which layer after layer of generational advances and innovations were applied to provide a home for a century, and now going into the next with our newest iteration. The long hours of work in this environment have focused my thoughts on the nature of engineering.

Engineering is the art of repetitive innovation

Each new iteration of our home over the last 100 years has been a blend of the best solutions from the past and modern advances, each time resulting in a unique structure that relies on the same strong foundation but incorporating its own unique advantages borne out of innovative solutions to old problems. In my version I add our current best solutions knowing that future remodelers will undoubtedly replace and update my work with their own improvements.

As a mechanical engineer I couldn’t help but see an analogy to my own work. I am fascinated by the process of solving complex technical problems. There is something so rewarding in applying physical laws to gain understanding and insight into a process or phenomenon and then leveraging that understanding to create something that solves a challenging and complex problem. As a practitioner of computational fluid dynamics my time is mostly spent searching for new solutions to problems involving complex fluid flow. Some of these problems have been around for more than a hundred years and have seen many varied solutions over the years such as basic flow valves or airplane wings. Others have been introduced to us as we seek to generate new technologies. CFD has been used in some form or another as part of the analysis and verification of many products but only recently have we had the technology to leverage it as a principle part of the design process and these design problems keep coming at us. Just as building materials and techniques have been required to advance so has the demand that we find better solutions to our engineering challenges. One of the fascinating things that I see happen over and over again in industry is when advances in one area or technology have the secondary effect of making other technologies obsolete.

The commercial aerospace industry provided me with one example of this. Constantly under economic and legislative pressure to create planes that operate more efficiently, engineers are engaged in a top to bottom search for opportunities to save space and weight. These improvements have resulted in a constant progression of improved efficiency. One of the results of the space and weight reductions required to attain this improvement has been that many of the auxiliary systems involved in operating the aircraft have less and less space available to them. At a certain point the technology relied on for decades cannot meet the necessary performance requirements in the reduced space.

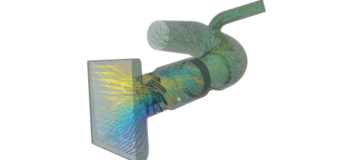

I was recently involved with a customer that was facing this exact struggle. The required space reductions in the nacelle and pylon had reached a point that the mixing system used to combine hot and cold air from the engine and turbofan for use by the HVAC and wing anti-icing system could no longer meet the minimum requirements. A new and innovative solution to this old problem was required. Using Simcenter STAR-CCM+ (the commercial CFD package from Siemens PLM where I work) we were able to explore 175 different design concepts with 12 geometric parameters and identify a new and innovative solution that could provide adequate mixing in the space allotted by the newly redesigned and more efficient nacelle and pylon assembly.

Sometimes it isn’t the technology itself that is forced to advance but rather our approach to designing it. This was highlighted for me recently when I worked closely with a company which manufactures thrust reversers for commercial aircraft. Thrust reversers are used to take the force generated by an aircraft’s engine (typically used to propel it forward) and redirect it to slow the aircraft down. The supplier had noticed an increase in the number of planes being certified based solely on the braking force provided by the aircraft’s disk brakes on the landing gear. Though their product performed well, they discovered that the cost in terms of time and capital that was required to design a thrust reverser for a particular engine was beginning to be seen as too high. In order to bring their product to market more efficiently they need to innovate their design process. Working together, we modernized their simulation process, automating it so that we could apply sophisticated optimization algorithms and efficiently explore many more designs then they could initially. Where they once spent 4-6 months iterating through 20-30 design candidates we could now look at more than 150 in less than 2 weeks. This wealth of information in such a short amount of time was exactly the differentiator that they needed in order to stay competitive in the modern market.

Every industry we work with has similar pressures driving them. The act of continuously evaluating and improving our products and our methods to satisfy these pressures is at the heart of great engineering. Companies who embrace technology and processes that naturally facilitate this kind of continuous innovation will continue to prosper while those who don’t will find that for a time they may be successful, but eventually they will be just like the last four remodels done on my bathroom, outdated, and ready to be torn out and replaced.

As I pulled out layer after layer from my bathroom I saw many techniques and materials that are still used today. As each new generation comes along we assimilate the best of what came before and through the act of innovation add our own best technologies. Truly great technology and design rarely arrive in a single burst of insight and innovation. But each step forward facilitates the next advances. By striving for great design and building on the best of what has come before us, we lay the foundation for tomorrow’s greatest accomplishments. I am still building on my 100 year old framing, making it my own and extending it to fit my modern needs. We have known the equations of fluid motion for nearly 200 years, been solving them computationally for about 50, and now building on top of this rich foundation we are routinely using them to virtually explore design ideas that we could only have imagined in the past. Every day we are finding ways to improve and advance the technologies that we all rely on as well as inventing the technology necessary to bring society into the future. It makes me grateful to participate in this process now. I don’t think there has ever been a better time to be an engineer and looking ahead to the future it will only get better.

Related Community articles & webinars:

- Thrust Reverser Design Webinar

- Design Exploraiton With Simcenter STAR-CCM+ Webinar Series

- What’s the latest in Simcenter STAR-CCM+ Design Manager

For more information, please visit our website: