Well control equipment: Metal hat, Fireproof coveralls… CFD

In the Oil & Gas industry, the integration of possible risk linked with well control — such as subsea plume, atmospheric dispersion, fire and explosion — is critical for minimizing impact on the entire system or on operations efficiency, and for ensuring worker health and safety. Risk to system integrity must be prevented at the design phase, but also addressed in case hazards happen along equipment lifetime or system in operation.

Last September 25th, Mr. Alistair E. Gill, from company Wild Well Control demonstrates the value of advanced structural and fluid dynamics mechanics simulation for well controls, emergency response and planning, as part of a Live Webinar organized by Siemens and Society of Petroleum Engineers. In this article I will try to summarize his presentation. To have more insights feel free to watch our On-Demand Webinar.

To be honest when talking about well control for Oil & Gas industry, people usual conception is that some disaster happened and guys wearing protections are trying to light off a big fire. Actually companies such as Wild Well Control are using modern and innovative techniques as Computational Fluid Dynamics (CFD) simulation to support practical team on a well control incident trying to keep asset integrity at the same time.

Mr. Gill provides several examples to demonstrate simulation techniques that were used from

- Subsea plume and gas dispersion modeling to understand where hydrocarbons go in the event of a blow out

- Radiant heat modelling in case of a fire

- Erosion modelling

- Thermal as well as Structural analysis

There is basically three major categories of simulation used, starting with everything related to the flow within the well bore, looking at kick tolerance, dynamic kill or bull heading; next anything to do with 3D flow using CFD simulation which is the main focus of this article; finally structural analysis using Finite Element modelling.

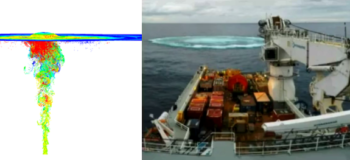

Subsea plume simulation

CFD simulation within Simcenter STAR-CCM+ is used to better plan an event and risks taken in case of well control event. For example, if there is a subsea blow out, simulation helps to determine what surface condition will be expected, and so how far emergency team and assets will have to stay away from the flammable gas cloud. How much gas we have to the surface? What is its concentration and is it flammable?

Image courtesy of SURE JIP

Image courtesy of SURE JIP

Mr. Gill also mentions importance of model validation in his project delivery for final customer to be confident with results and conclusion brought by Wild Well Control. With the subject of Fluid Dynamics, which is such a non-linear subject, validation is important. This is why Wild Well Control is part of Subsea Underwater RElease (SURE) project. SURE members perform various experiments to validate and develop CFD models you can trust. Comparison is made on bubble size, velocity, density, gas fraction as examples.

Same philosophy is shared with Siemens Simulation and Test Solutions segment (STS). Simcenter portfolio not only covers simulation capabilities but also Testing hardware and expertise which has been used by our customers but also internally since years to validate developed models.

Additional applications

Once you have studied subsea plume formation, you can also look at capping stack deployment simulation to compute hydrodynamic forces impacting capping stack position control onto the well head. Simcenter STAR-CCM+ is used in association with a six degree of freedom model of the stack on its lifting wire to cover this application. Very interesting.

If gas is surfacing, Wild Well Control can answer how far gas extends from the point of the release using 3D CFD simulation when a natural airflow offshore situation is concerned.

In a fire situation, radiant heat needs to be considered too especially when multiple wells can be impacted by the one on fire. Again, Simcenter STAR-CCM+ is used to include multiple physics: species transport and reaction model and radiant heat model. Objective is to help final customer to avoid escalation of the event.

Additionally, time to failure can be better predicted via erosion simulation, using CFD, especially for complex geometry components. Highly non-linear analysis due to moving pipe walls is eased thanks to moving deformation mesh function from Simcenter STAR-CCM+.

Finally, Mr. Gill mentioned that simulation technology is also used to understand what happened during a particular event and find the cause, plus other topics that, again, you can discover watching On-Demand Webinar.

If you want to see several more Webinars and so applications of Simcenter portfolio in a wide range of industries including Oil & Gas, please check Siemens Events webpage.