SimRod experience: Model-Based System Testing in practice

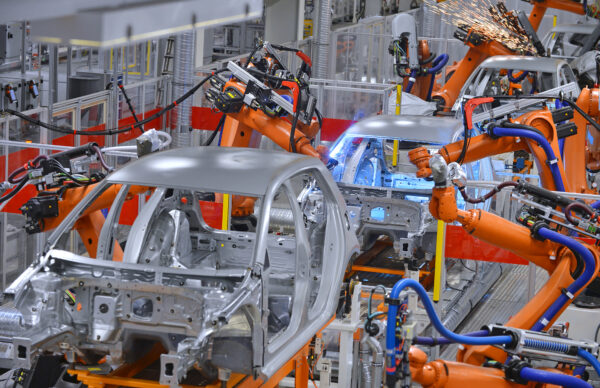

Last week, I ordered a new car. It took me a long time to decide which brand and model to pick. Once I decided on that, I thought, OK, let’s sign the order form. But then, the options list in the car configurator tool totally overwhelmed me. It took me again a long time to configure my dream vehicle.

Waiting for my personalized prototype…

Now I am waiting for my car, the global chip shortage gives me some time to think. I did not go through the math, but there must be hundreds, if not thousands, vehicle configurations of the car I ordered. That scares me quite a bit. I will probably be driving a prototype car, the first-ever produced with the combination of options I selected for that particular vehicle variant. You should know that I am an electromechanical engineer, I graduated 30 years ago and spent my entire career around performance testing… so my instinct says, OK, I’ll test the prototype myself. This must feel like an exam for the people responsible for vehicle performance validation. Imagine the stress, 99% of the customers are driving a vehicle that has never even been assembled during the performance testing phase.

Component-based performance validation

Luckily, over the last decades, testing technology has evolved quite a bit. The basic principle of this evolution: validate the performance of each option in the car configurator on component level. Today’s component tests should be designed such that the results can be used in a virtual performance validation process. Configuring a car, picking parts from a list of validated components is your guarantee for good full-vehicle performance, right? Hmmm…. As I said, it is a principle. And like with any other principle, the devil is in the detail.

Model-based system testing

Being pioneers in this testing technology revolution, we took care of those details. In the Simcenter platform, we implemented a model-based system testing framework that brings this principle to life, killing the devil :>). If you want to know some of those details, check this blog about model-based system testing by a good friend of mine, Simona. Or visit our website and find out more.

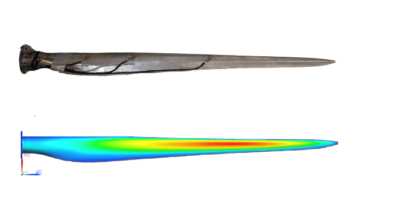

SimRod motor put to the test

Being an engineer with a test background, I could not resist putting this very principle to the test. We applied it to the e-motor and controller of our technology demonstrator, the SimRod vehicle. We mounted those components in a test bed designed to accurately mimic the behavior of the rest of the vehicle. Using Simcenter Testlab and Amesim, we tuned this setup for maximum fidelity. Doing this, we were able to accurately reproduce a random drive cycle. From this test bench, we derived models we can use for virtual vehicle performance assessment and subsequent design optimization. As a result, these models become essential assets for both the OEM and suppliers. Check this video to find out more.

Now I can only hope that the car I ordered was designed using this principle…