What’s New in Simcenter 3D 2022.1

Simcenter 3D helps you conquer engineering challenges. As the most comprehensive, fully-integrated CAE solution, you can work across simulation domains from a common engineering desktop. The Simcenter 3D development team has had an extremely productive year, and we are pleased to share what’s new in our latest release – Simcenter 3D 2022.1.

New enhancements in Simcenter 3D are aimed at helping you:

Model the Complexity

Your products are complex, and you need to accurately simulate and predict performance by capturing the right physics, geometry and operating environment. Simcenter 3D’s multidiscipline integration helps you simulate real-world conditions more accurately, seamlessly transfer data and streamline multiphysics workflows. Here are some of the highlights from the 2022.1 release that help you model the complexity of your products better:

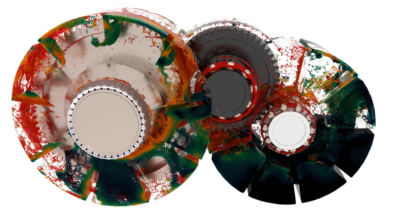

Enhancements for turbomachinery simulation

Simcenter 3D has become a leading tool for turbomachinery analysts because it seamlessly combines all of the physics and streamlines the multiphysics workflows required to simulate these complex machines. Turbomachinery-specific enhancements include:

Thermal Multiphysics

Include 3D CFD in portions of the Whole Engine Model

Add 3D CFD to portions of the model and support convection to axisymmetric meshes and connections to the 1D fluid network. This means you can connect 3D fluid simulation domains in a cyclic symmetric model defined with axisymmetric elements that are commonly used to model a turbomachine cross-section.

Rotor Dynamics

Account for the interstage junction between two stages of cyclic symmetry

When a rotating machine is made of different stages of cyclic symmetry, you must consider the interstage junction. Couple different cyclic fields at the interstage junction by adding different fundamental higher-order harmonics.

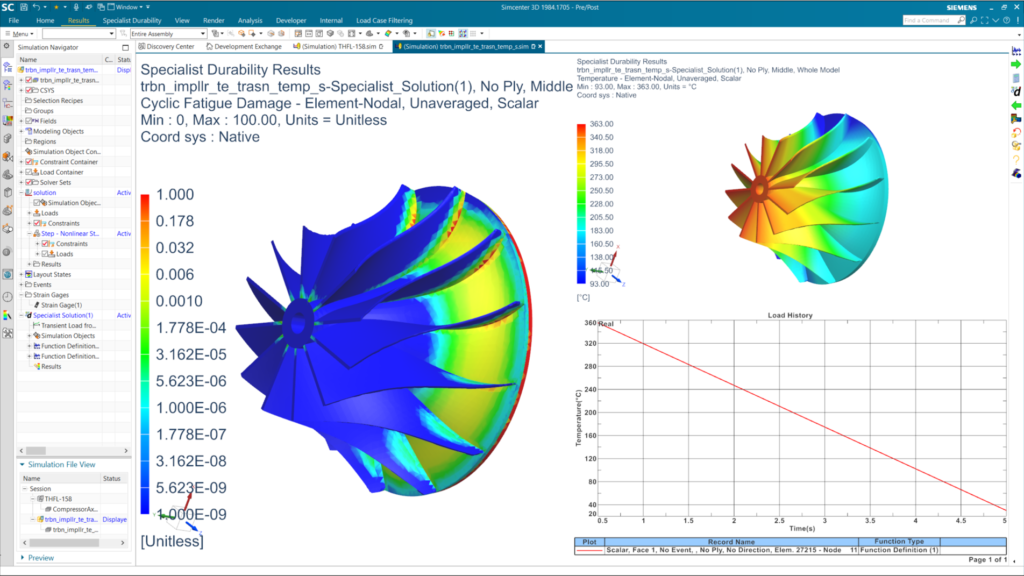

Durability

Time varying thermal fatigue

Understand durability over real operational cycles and reduce modeling time by reading temperatures and stresses/strains from FE results and ultimately perform temperature-dependent fatigue analysis.

Multibody Dynamics

Spiral bevel gear support

Perform accurate, system-level NVH analysis on mechanisms with spiral bevel gears, such as automotive differentials. This can help you better understand the noise these systems generate, so your customers can enjoy a quieter ride.

Structures

Drop test application

A new dedicated app that you can add onto Simcenter 3D to help simplify and streamline the entire drop test simulation workflow – from model setup, to solve, and results postprocessing. Results templates and reports help engineers, who are not expert analysts, understand the results of their drop test simulations more easily. This allows them to quickly make the design modifications needed to ensure their devices can better withstand our clumsiness.

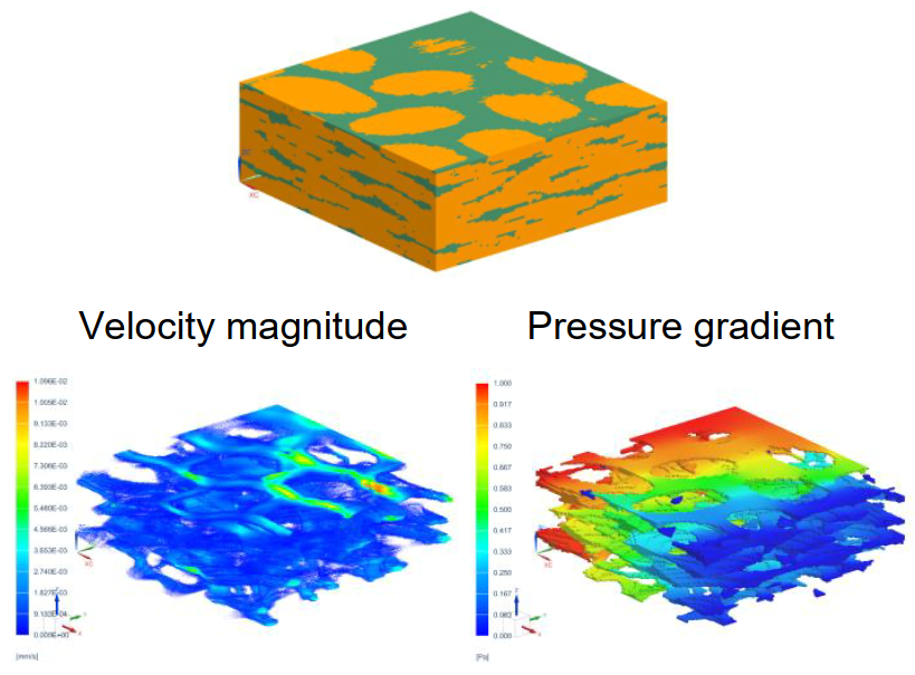

Materials Engineering

Homogenize permeability of porous structures

It’s not feasible to perform a CFD analysis on a material with microscopic pores. So instead, given a unit cell or microstructure model, you can homogenize the permeability accounting for the microstructure. You can then use that permeability data in larger scale models to further predict flow at the global scale to enable multiphysics workflows.

Additive Manufacturing Process Simulation

Flexible build plate

The additive build process creates large residual stresses and strains in parts that can also result in excessive deformation of the build plate after bolt removal. This can make it difficult to remove parts or can cause you to scrap an entire build. In this latest release, you can now define a flexible build plate and calculate the stress build-up in the plate bolts. This lets you see how the build plate will deform after removing the bolts.

Test-Analysis Correlation

Correlation for acoustics

and vibro-acoustics

Acoustics and NVH engineers can now fine tune their simulation models to match real physical test data so that they can be confident that future simulations will more accurately represent what will happen in the real world.

Go Faster

The traditional simulation process is perceived as too slow. Simcenter 3D eliminates the simulation bottleneck through more efficient simulation processes. The following enhancements in this release help you speed modeling and simulation so you can spend more time engineering:

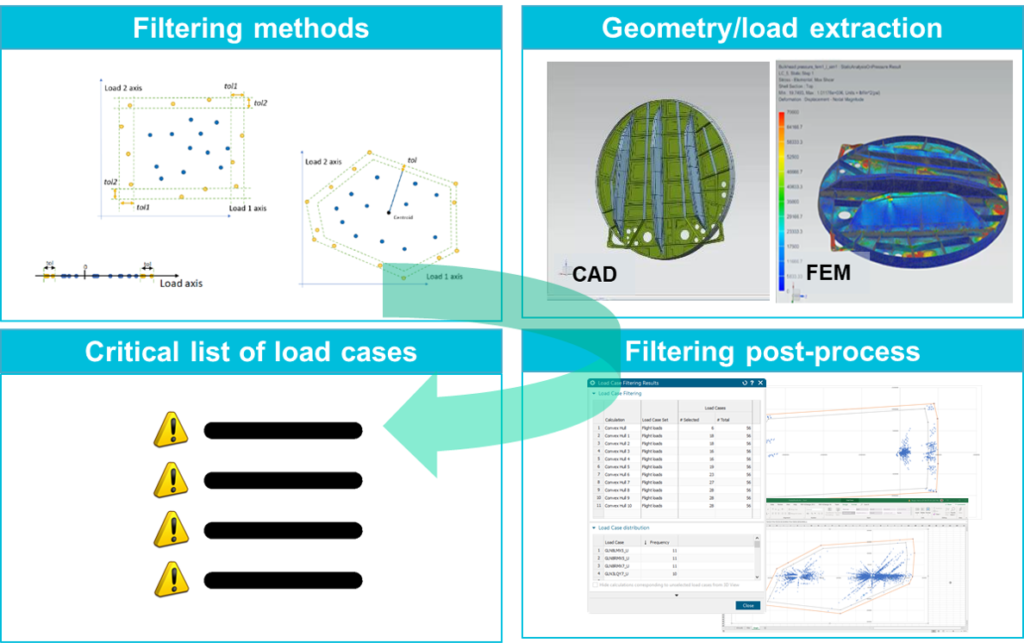

Aerostructures

Load case filtering

Searching and filtering to find the most critical load cases that most influence certain aspects of a design is a tedious and time-consuming process. Simcenter 3D leverages CAD and FE model integration to help you quickly define filtering methods. Rapidly extract the loads and their related geometry and ultimately determine the final critical list of load cases.

Acoustics

BEM adaptive order method

Get acoustics results up to 10X faster with new high performance boundary element method with adaptive order solution (BEMAO). BEMAO also saves you modeing time since you can start with a very coarse mesh.

Explore the Possibilities

Simulation needs to happen at all stages of development – including in the concept and design stages. Enhancements in this release of Simcenter 3D help democratize simulation beyond the realm of simulation experts:

Democratization

NX Topology Optimizer

Topology optimization capabilities for designers have an even tighter integration with the NX environment. The user interface (UI) now includes a new ribbon bar and navigator specifically for topology optimization. Additionally, Topology Optimization is now a ‘replayable’ feature in the part navigator tree, where it reacts to upstream changes just as a designer expects.

Acoustics

Multi-track auralization

Listening to results helps designers more easily understand the impact design choices will have to the end customer experience. Simcenter 3D has extended the auralization capabilities to support multiple tracks so you can mix all contributing sounds and listen to the combined results so, for example, you can hear how your loudspeaker will sound in a car cabin combined with road noise.

Stay Integrated

Finally, simulation shouldn’t happen in a vacuum. Simulation is just part of the overall development process, and these enhancements in Simcenter 3D help you keep simulation integrated with that process:

Engineering Desktop

Teamcenter Share

Available to Siemens Xcelerator as a service (or XaaS) subscribers, Teamcenter Share is a new way to integrate the development workflow across the Siemens Xcelerator portfolio for small companies and workgroups. This collaborative cloud environment works across NX, Simcenter 3D, STAR-CCM+ and many other tools, so that users of these tools can seamlessly share files and communicate results to each other.

Engineering Desktop

Remote simulation

Easily connect and launch simulations remotely to any workstation running Windows or Linux on your network. You can then monitor the progress of an active solve right from your web browser to ensure it is progressing properly.

Multibody Dynamics

MF Tool for tire data

As part of the Simcenter portfolio, we continue to further integrate Simcenter 3D with other solutions within Simcenter. MF Tool integrates and streamlines the entire process of obtaining real tire data that can then be immediately used in your simulations. MF Tool transforms measurements obtained from physical tire testing into tire data that is used in Simcenter Tire. The tire data can then be used in vehicle multibody dynamics simulations in Simcenter 3D Motion.

Learn more…

Comments

Comments are closed.

Nice !! Thank you guys at Siemens for such a big amount of new fonctionnalities in the release 🙂