What ancient Greek shipbuilders can teach jet engine manufacturers

An ancient paradox

The ship of Theseus is an ancient question and paradox of what an object really is and what happens when switching out parts. When a boat is out at sea, it goes through harsh environments and weather. During the lifetime of the boat, you might switch out planks, masts, and sails. If all parts are replaced, is it still the same ship? Or, if you take out the parts from the original ship, and use these parts to build another ship, which one is the ship of Theseus?

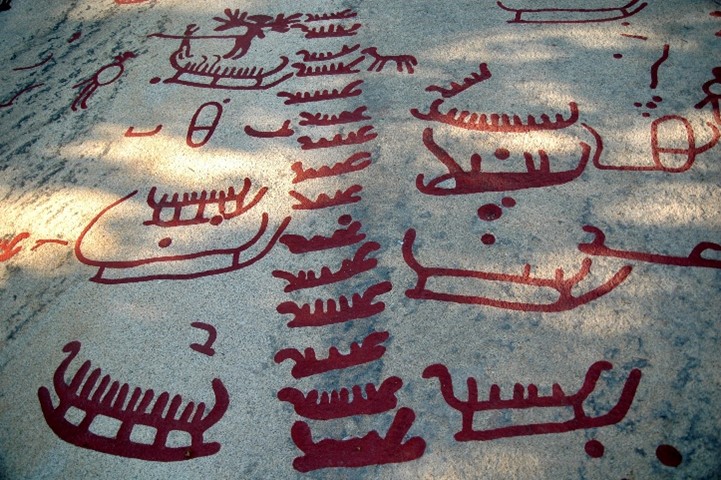

A millennium prior to Theseus’ philosophical question, ships from the Mediterranean might have made it all the way up to Scandinavia. This is 2000 years prior to any Vikings setting sails. The boats being depicted in rock carvings found in Sweden at this time were not made by the inhabitants. However, these simple lines could have sparked their imagination and inspired them to start their own marine adventures.

An interesting piece of history is that the Vikings made their way from Scandinavia over the Atlantic to Iceland, Greenland and at least to the Hudson River. They called the region Wineland, (the region today known as Newfoundland), which was lush, green and full of grapevines. Climate since then changed and became much colder after the 14th century, and no Viking settlements survived to the point of Columbus’ arrival much further south.

A new era

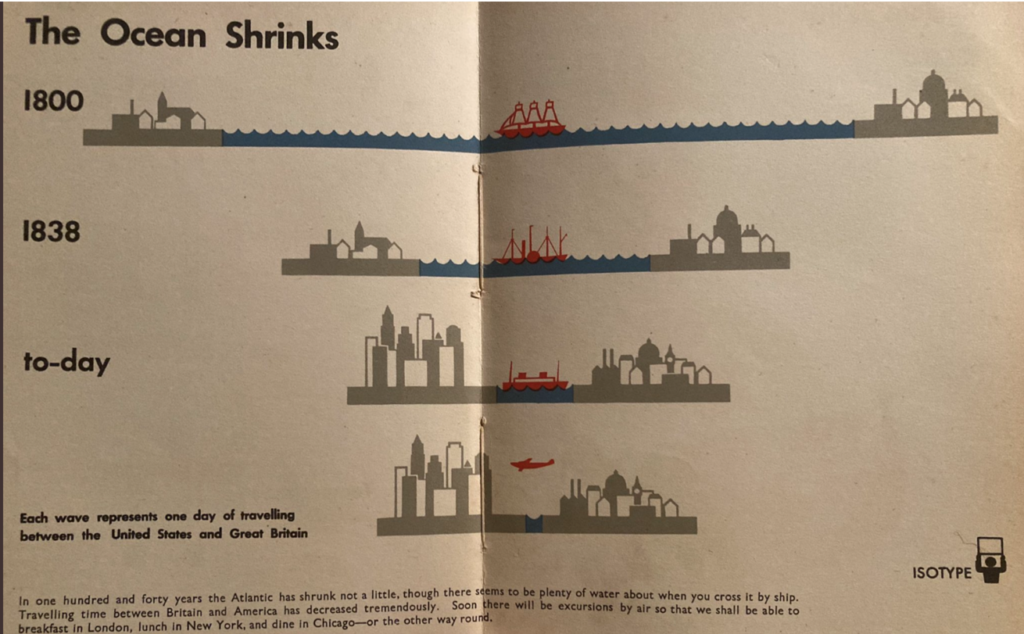

What does ancient shipbuilding have to do with aerospace and jet engines? In the past, it used to take many weeks to travel across oceans. However, today, with an airplane it only takes a few hours.

Thanks to advancing technology, ships and navigation has been successfully developing over a few millennia. This has caused the ocean to “shrink” as additionally, new materials and engine technologies have managed to bring about new types of ships from Europe and America.

With digital technology, the internet and a wish to be less reliant on fossil fuels, a new era has begun in the history of humankind. Telegraphs, telephone, internet, and lightning-fast communication over the oceans. Jet engines have enabled faster, more efficient aircraft propulsion. Still, there is an increasing need for people to travel, meet and transport goods over the oceans.

A historical perspective is important but won’t lead to innovations. Many things are hard to predict. The future being particularly difficult. But let’s have a quick look into the near future, the challenges that come with it and the tools that will help you build whatever propels you into a new era. Where today meets tomorrow.

Rethinking jet engine design

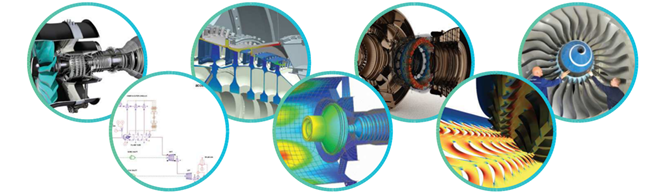

- Decarbonization through new fuels such as SAF and hydrogen for longer flights

- New aircraft propulsion configurations, such as electric motors and batteries for a shorter flight time

- Maximized thrust and efficiency and reduced noise with new engine designs

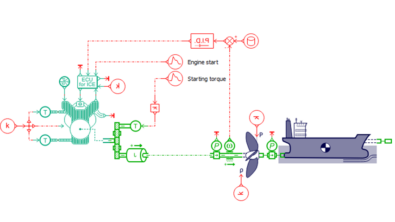

With digitalization technologies such as model-based systems engineering and product lifecycle management, you will be able to engineer the entire system and have traceability of each part prior to building and testing it in real life. Multidisciplinary design space exploration and automated workflows enable you to find unintuitive designs with high reliability and controlled risk management.

Digitalization is a key factor for jet engine program success

- Break down silos between engineering teams and connect design, engineering and manufacturing directly (CAD CAE, CAM). Enable casted, 3D-printed and machined parts, blades and vanes to be brought from the factory faster

- Tackle complex technical issues such as efficient blade cooling as well as whole engine asymmetric cooling and understand thermal and dynamic deformations to keep rotor/stator clearance under control

- Mitigate risks of new fuels by modeling complex phenomena and higher-order combustion physics in a more integrated way between systems, fluids, thermal and solid mechanics.

Realize innovative and reliable engines

Simcenter, which is part of the Xcelerator portfolio, offers complete and validated CAE solutions to address design challenges with design exploration, workflow automation, simulation process and data management. Moreover, Simcenter offers the possibility to connect to Xcelerator Share, an engineering-centric, cloud-based solution for ad hoc collaboration, which will allow teams of all sizes to collaborate securely.

- Siemens’ comprehensive digital twin supports the digital thread from model-based systems engineering through sustainment. This foundational platform can provide a seamless lifecycle for aerospace programs and its industry partners.

- The end-to-end model definition, simulation-driven lifecycle and adaptable processes deliver a completely navigable set of program information by ensuring the mission, requirements and architectures are always visible and traceable throughout the downstream lifecycle. This helps enable the speed and flexibility required to continuously adapt to the changing priorities and conditions.

- Siemens’ open ecosystem and architecture allow both new and existing programs to transition to the most advanced digital transformation capabilities available. This structure helps create a common foundation across programs, service branches and industry partners to help advance capabilities across programs very quickly while enabling an open architecture.

With digital technology, we can follow each part from the ship of Theseus question. Siemens Digital Industries software can help you accelerate your digital transformation. Improve your current digital strategy and unleash your team’s potential with the right tools.

Want to know more about jet engine engineering?

- On-demand webinar – Jet engine design with a digital twin

- E-book – Jet engine engineering

- ATA Engineering case study – Digital twin of engine air brake

Looking forward to seeing you at Turbo Expo 2023!