Simcenter Testlab 18: Sound and Satellites?

Would you associate the concept of sound with satellites? Well, maybe not, as sound does not propagate in deep space… But have you thought about satellites being exposed to acoustic waves during their lifetime? Until the spacecraft reaches its orbit, it is subjected to very extreme environmental conditions, where many kinds of dynamic loads may affect its components and subsystems, or even cause failure of these.

Check this animation of the Ariane 6! This is the launch vehicle developed and manufactured by ArianeGroup under the authority of the European Space Agency (ESA), which has its first test flight scheduled for 2020.

Watch the video here!

Note that during the first seconds, the satellite is encapsulated in the so-called spacecraft vehicle’s fairing. This structure, also called payload fairing, is used to protect the spacecraft against the impact of dynamic pressure and aerodynamic heating during launch through the atmosphere. Anyway, there is still a lot going on inside the fairing !

No matter the brand, type or size of launch vehicle: the sound pressure levels the satellite is exposed to can easily exceed 130-140 dBSPL overall values!

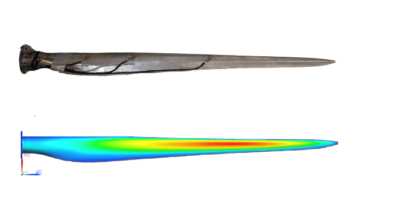

How “loud” is that? Enough to produce significant vibrations which may compromise the functionality of lightweight solar panels and reflector shells of antennas, the subsystems that are most vulnerable to the acoustic excitation.

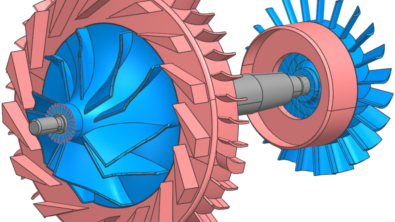

How is this potential damage avoided? Prior to the launch, the space hardware must undertake dynamic environmental tests where representative sound pressure level of the operational condition is reproduced in a controlled environment. The most traditional environmental acoustic testing method consist in generating the noise in a large reverberant room, prepared for spacecraft testing. In this way, acoustic tests ensure that space hardware will survive the operational conditions endured during its launch phase.

Source: Courtesy of ESA and Thales Alenia Space

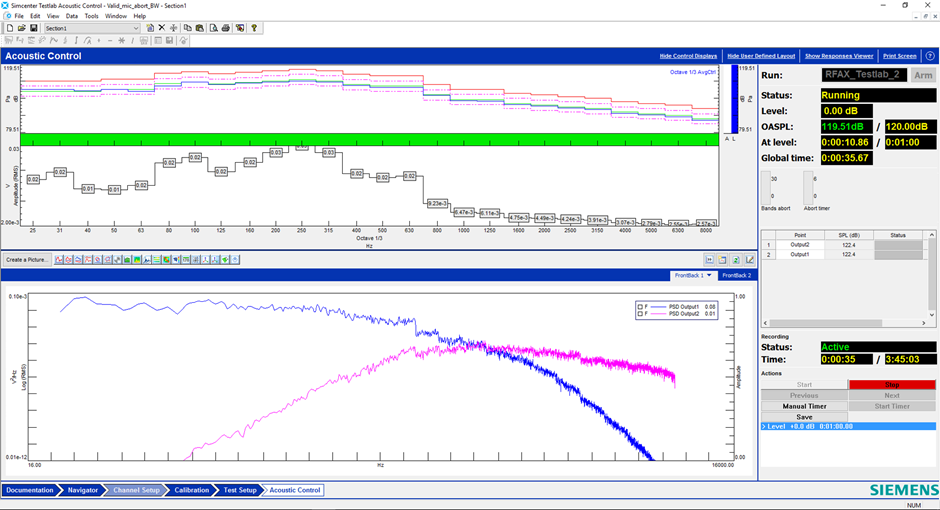

How can you make sure that the noise generated in the reverberant room accurately reproduces the operational environment? Simcenter Testlab Closed-loop Acoustic Control solution is designed to perfectly control the sound pressure level in reverberant rooms. It also responds to the most stringent safety and tolerance requirements used in the space industry.

This is how your software interface looks when you are performing the environmental acoustic test with Simcenter Testlab Closed-loop Acoustic Control.

While testing against severe acoustic loading, vibration levels at hundreds of measurement points on the space hardware need to be recorded and analyzed too. Siemens has developed throughout the years a complete and robust solution for space labs. All the environmental control and data reduction products are designed to perfectly meet the needs of the industry.

With Simcenter Testlab 18, Siemens adds state-of-the-art solutions to offer a complete suite for mechanical qualification of space hardware. The control algorithm of the Simcenter Testlab Closed-loop Acoustic Control solution for reverberant rooms has proven its worth in several acoustic facilities around the world and is ideally connected to a data acquisition (or reduction) system for online processing of hundreds of channels recording/monitoring vibration data. Simcenter Testlab Closed-loop Acoustic Control allows to easily setup a reference profile (in 1/1 or 1/3 Octave bands) and automatically control the drive feeding the amps/modulators/horns so that the average sound pressure level measured by the control microphones matches the test requirements.

Interested in other Dynamic Environmental Testing solutions for Vibration or Shock Control? Check our website!