Discover the new era of engineering with Simcenter

As of today, you can discover how we consolidated our vision on product design and engineering in a new solutions portfolio. By bringing Simcenter™, we will help you effectively deal with the challenges that are related to today’s complex product development.

All manufacturing industries need to address similar design concerns. Their customers want smart products, tailored to their personal needs, preferences and habits. And at the same time, they continue facing the ever increasing demand for energy efficiency, and the traditional pressure on cost and time-to-market. All this while products still need to be as durable as they were before, and adhere to brand values.

To successfully handle all of these issues, design and engineering have to evolve. Manufacturers will have to deploy a new set of development tactics and tools that allow them to better predict product behavior, even beyond manufacturing, when the product is in use. They will need to step beyond a classic verification and validation approach into a new process that allows prediction over the entire product lifecycle.

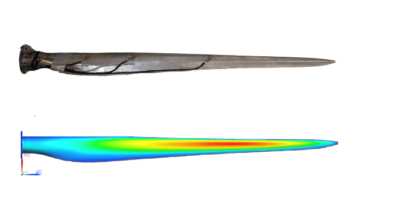

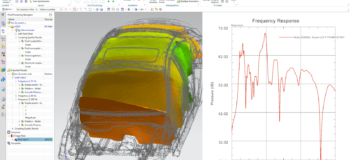

Simcenter bundles the strengths of NX CAE™, LMS™ solutions and CD-adapco® solutions in a new comprehensive portfolio. It strongly aligns 1D multi-physics simulation, 3D CAE and physical testing, and combines this with intelligent reporting and data analytics. This will help you create a Digital Twin, a replica of the real product that behaves exactly the same, and stays in sync.

Simcenter will enable you to support systems-driven product development by what we call predictive engineering analytics, a step up compared to classic verification and validation. Using this process, you will be most effective in finding the right balance between functional performance requirements during the early design stages. You will model components and full system assemblies with the highest detail. And you will weave the digital thread through the product lifecycle that is required to continue design after delivery.

Read this KB article to discover what changes for our 3D Simulation users