What’s new in Simcenter systems simulation 2404

With the release of Simcenter systems simulation 2404, new valuable features are added for its users to help them transform engineering and get ready for tomorrow’s challenges. In this blog we highlight several new features from this release, including Simcenter Amesim, Simcenter Flomaster and Simcenter System Analyst.

Platform

Simcenter Amesim 2404

Simcenter Amesim 2404 offers several new features that will make the life of most of its users easier, independent of the libraries or solutions that are being used.

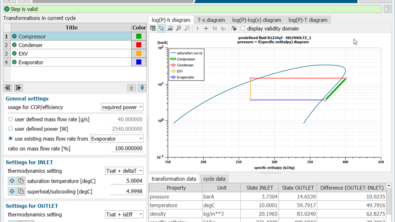

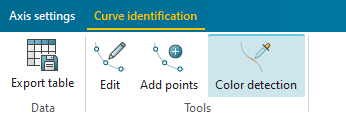

Take for example the enhancement of the graph digitizer. Simulation engineers who need to retrieve numerical values from a part specification curve in a printed image can now also use color detection to extract curve data based on the line color, making it easier to use parts of suppliers’ catalogs in their models even if the characterization data are not fully accessible.

The CAD import tool has been improved with a seamless way to extract CAD geometry of a mechanism. This means that error-prone manual steps are avoided from the model set-up process and users can now fully take advantage of the benefits of the recursive method of the 3D Mechanical library.

Simcenter Flomaster 2404

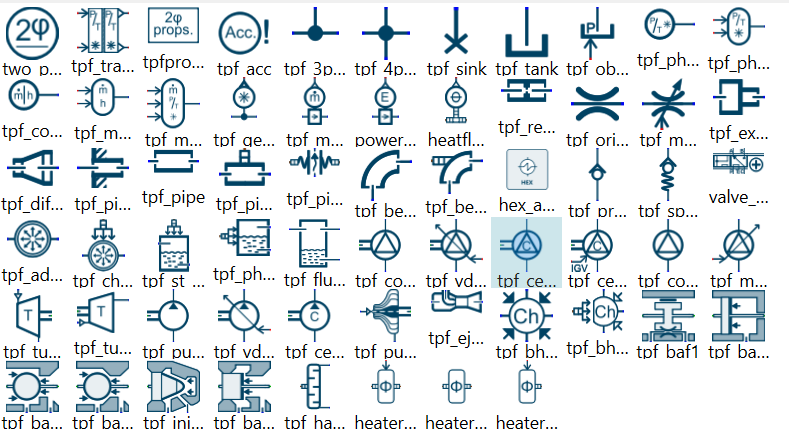

For Simcenter Flomaster 2404 we highlight two new features that have been added to make pipe scheduling and reporting easier, and makes it possible to deploy system simulation models in real-time operational environments.

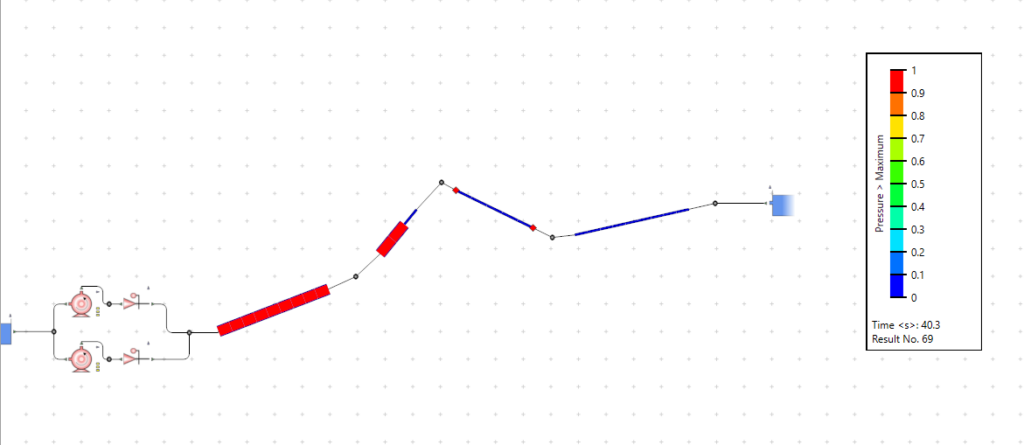

For fluid system design engineers who need to check that the pressures in the system don’t exceed the pressure ratings of the pipes in their systems, the new pipe scheduling and reporting enhancements allow the entry of the minimum, maximum and working pressures and validation during the simulation. This enables users to enter data on pipeline operational requirements in one place and then validate systems against those requirements without requiring additional post-processing steps.

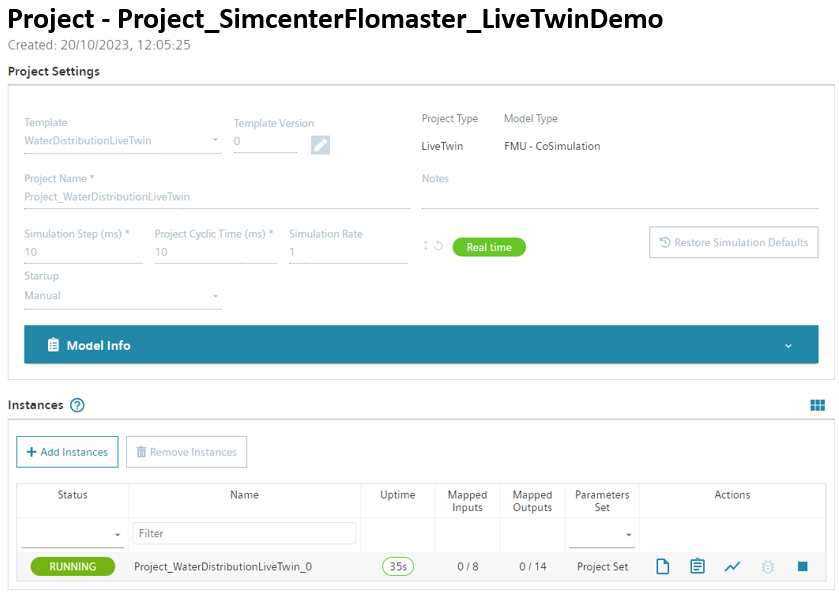

The second highlighted new feature opens new opportunities to extend the life of simulation models into the operation phase and realize their full potential. As of release 2404, users have the ability to robustly deploy full-fidelity simulation on the Industrial Edge platform and use their models for virtual sensing, operator training, virtual commissioning, leak detection, sensing in extreme environments, and optimization of their processes. This is an important step when preparing and transforming simulation models for use as an Executable Digital Twin (xDT).

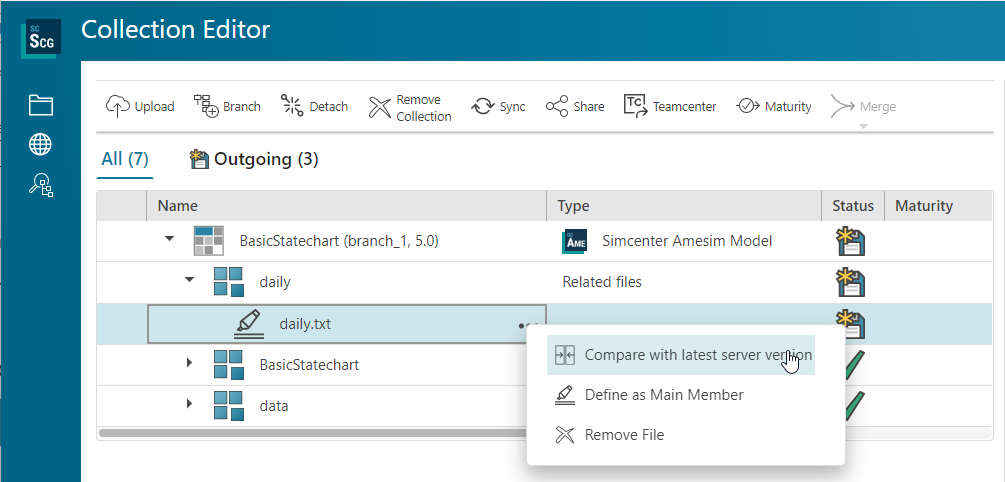

Client for Git

For Client for Git users new features are added for their daily work. Users can now instantly recognize that a folder is being managed by Client for Git when using Windows File Explorer with the new folder icons per collection type. Also, as of now, it’s not required anymore to download different file versions and compare them manually outside Client for Git environment, thanks to the new configure compare and resolve tools.

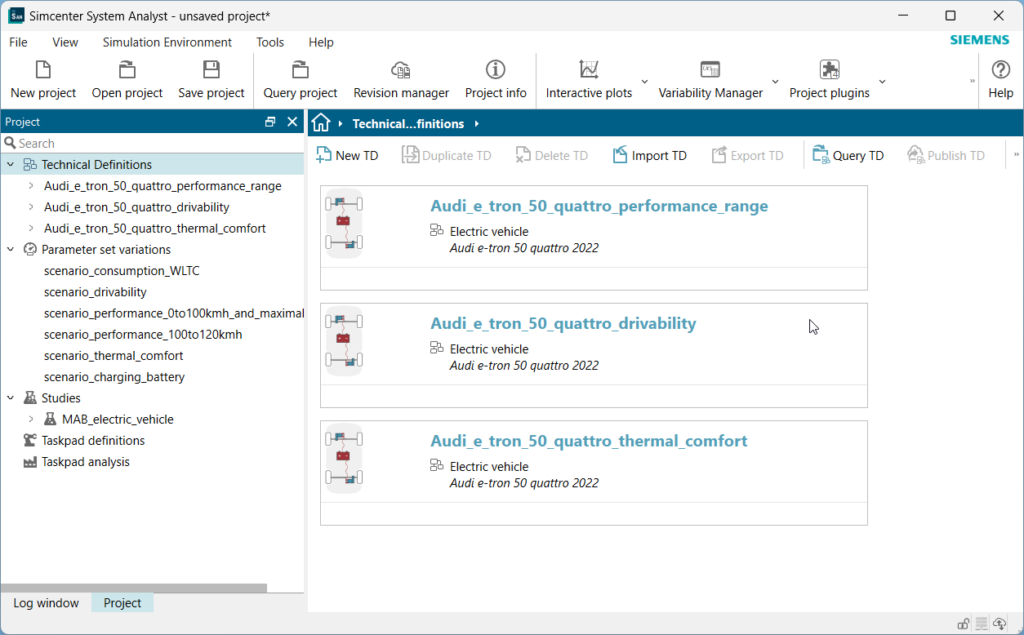

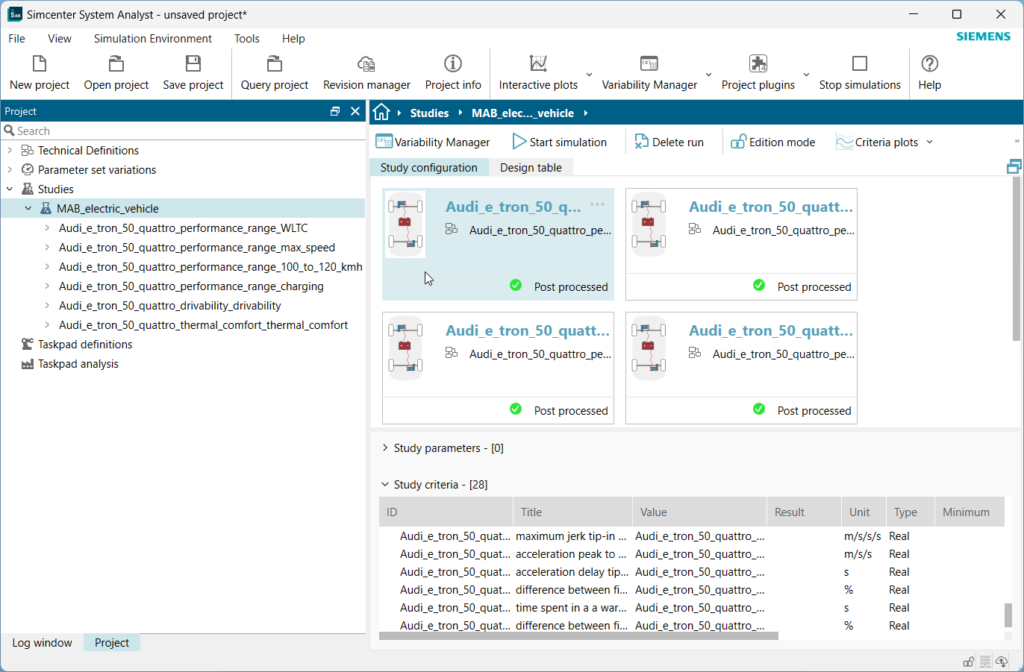

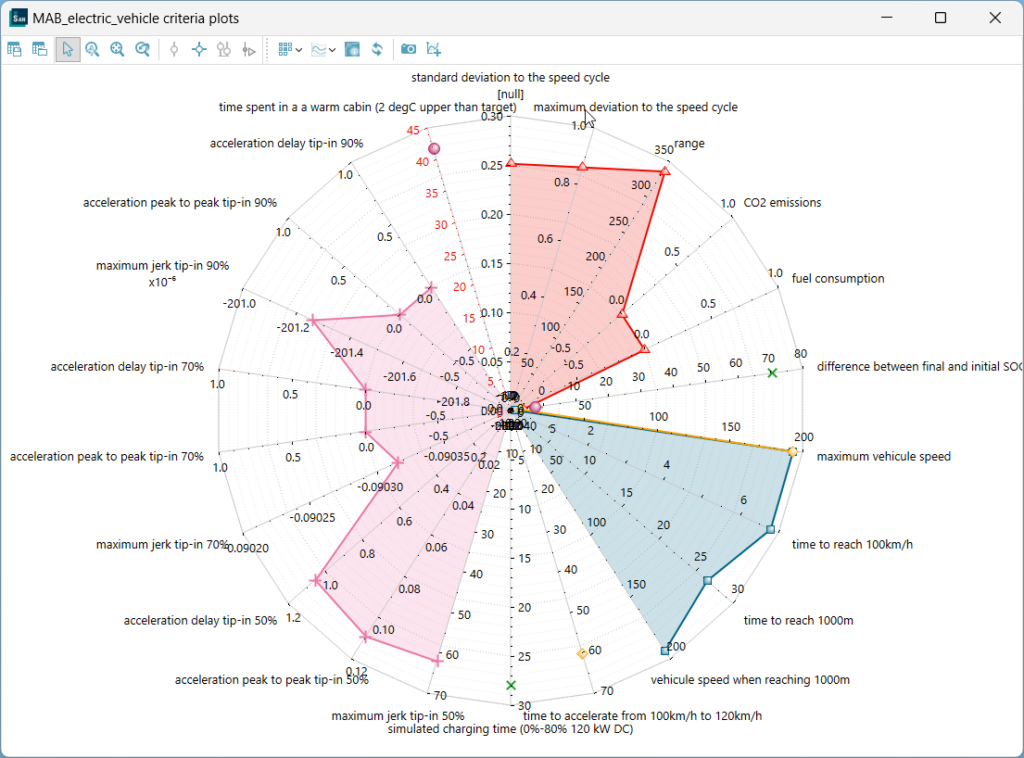

Simcenter System Analyst 2404

In Simcenter System Analyst a new automotive demonstrator is available for multi-attribute balancing. This demonstrator shows how Simcenter System Analyst can provide a central dashboard for configuring and optimizing an automotive system across multiple types of analysis (performance, range, drivability, thermal comfort and more). This means that engineers can save time to get the optimum system, by reducing iterations between the teams, and be sure that all attributes have been evaluated with the right system configuration.

The demonstrator offers many advantages:

- A central dashboard for configuring and optimizing a system

- All system attributes can be evaluated in one place

- A single source of truth for parameters and system bill of material

- Including 13 predefined electric vehicles to test and practice the process

- Less iterations are needed between teams to go faster to get the best optimum product configuration

- Ensuring to use the up-to-date system configuration when optimizing a system

The demonstrator is based on automotive examples but can be applied to any industry.

Industry applications

Automotive

Simcenter systems simulation 2404 offers exciting new features that will help to make ground transportation cleaner and better drivable.

The new drivers app in Simcenter Amesim 2404 offers automatic characterization maneuvers to set automatically all the longitudinal 1D and lateral 3D driver parameters. This makes it easier to tune the parameters needed for robust driver models.

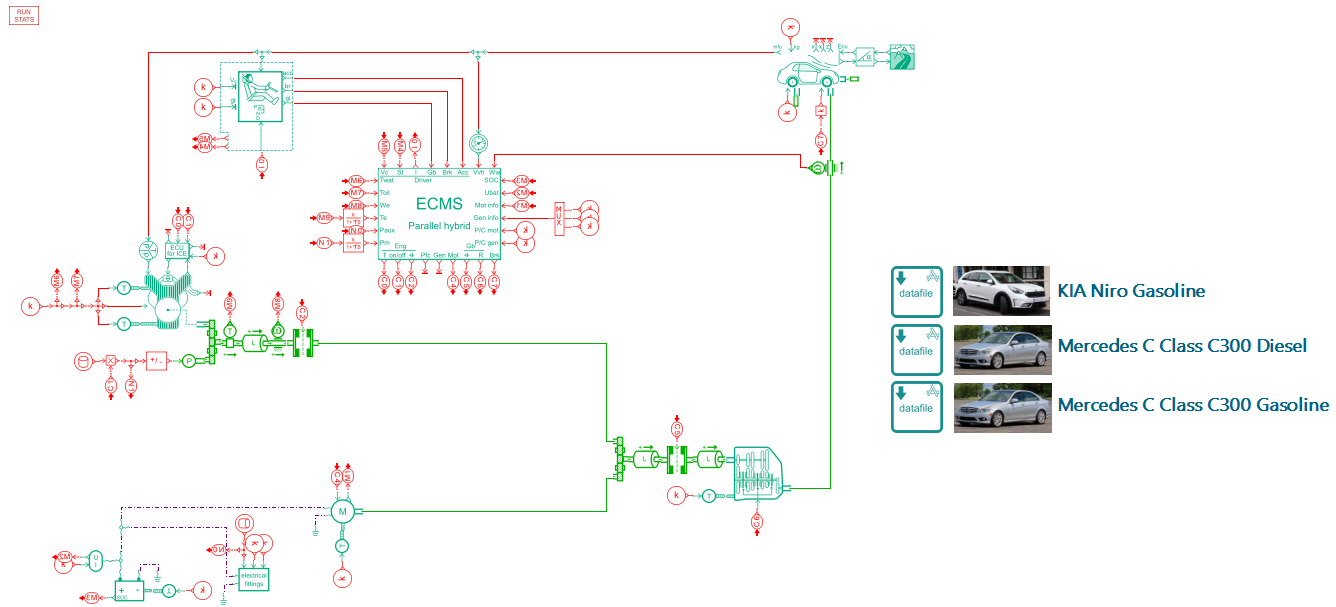

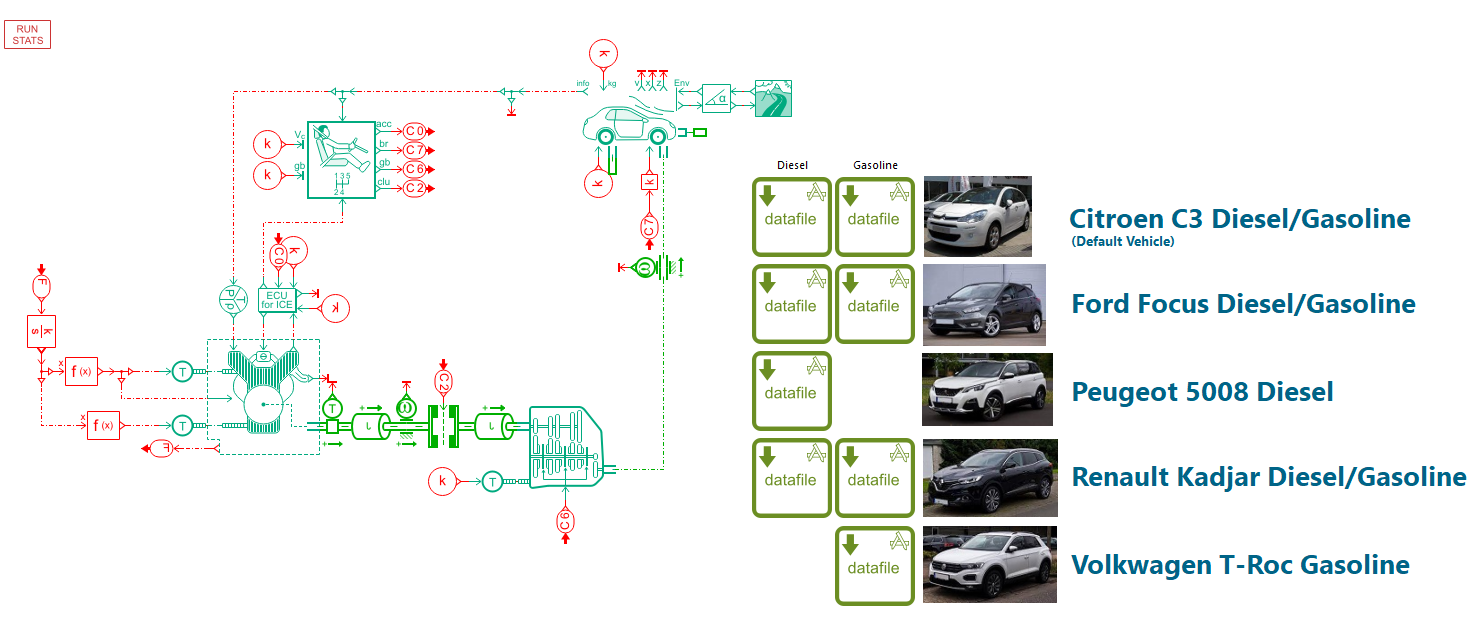

The vehicle database has been extended with a new set of IFPDrive demo models of 13 new readily parametrized vehicle models (5 gasoline, 5 diesel, 3 PHEV). This makes it easier for automotive performance engineers to compare fuel or electric consumption of any new energy management or control strategy change. These models can also be used as a starting point to refine any subsystem modeling (battery, inverters, electric motors).

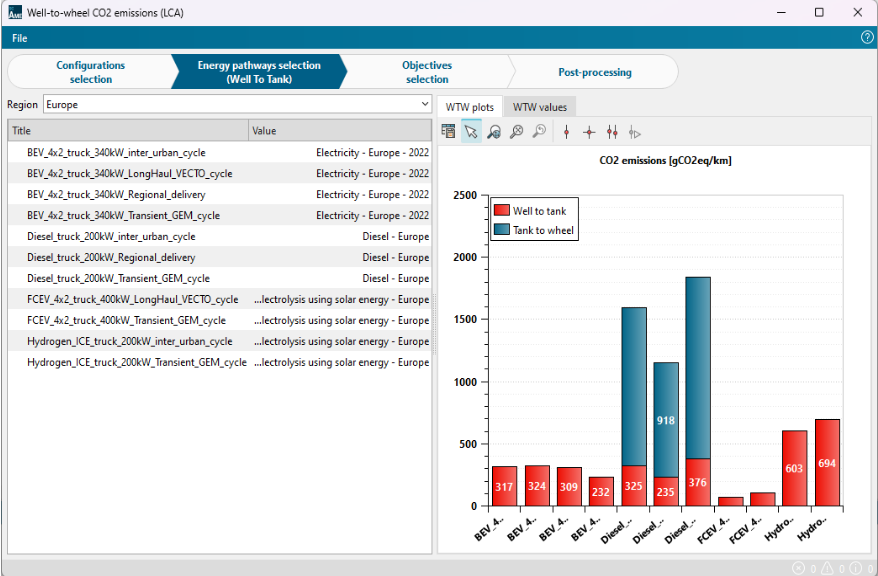

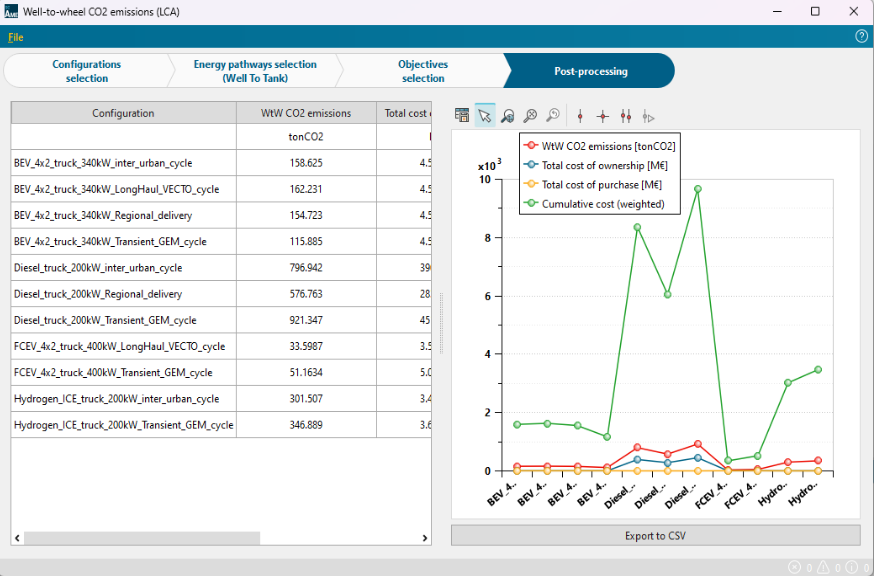

Scaling up from vehicle-level to fleet-level, the well2wheel vehicle fleet app in Simcenter Amesim 2404 offers many different energy sourcing pathways (ethanol, electricity, diesel, gasoline) for different worldwide countries or regions. This means that it becomes easy to compare fuel or electric consumption and the related carbon footprint of any vehicle fleet with cars or trucks. Evaluating new vehicle energy management or control strategies will become easy for an entire global vehicle fleet. Engineers can also re-use any already created vehicle models and refine any subsystems to reduce carbon foot print on different driving cycles.

Aerospace

For Simcenter Amesim 2404 users in the aerospace industry, three features are highlighted.

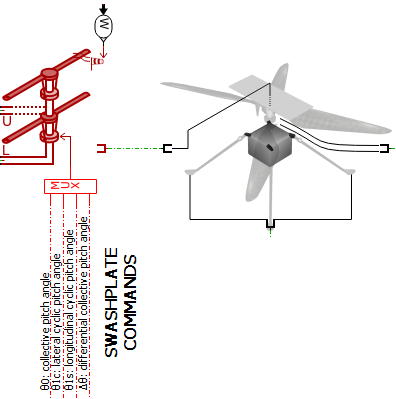

For control engineers who need to design and test rotorcraft autopilots, whether it is for a single stage or contra-rotative coaxial rotor configuration, Simcenter Amesim 2404 offers a set of rotor submodels with cyclic pitch control. Thanks to this new capability, engineers can easily assess how key rotor parameters, such as blade geometry and the presence or absence of flapping hinges, affect rotorcraft maneuverability. Ultimately, they can calibrate the controllers to ensure rotorcraft stability.

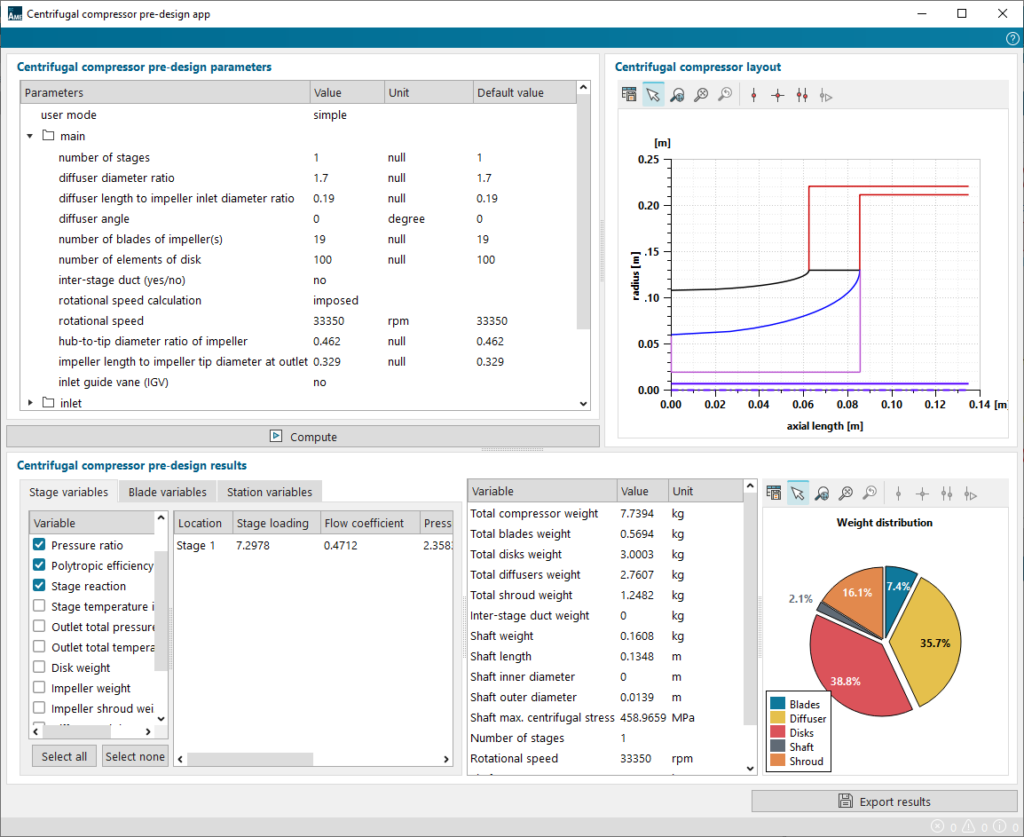

Often used in aerospace but also in other industries, users developing or using centrifugal compressors can now leverage the new centrifugal compressor pre-design app to quickly get a preliminary geometry of a centrifugal compressor meeting given performance requirements. This means that users can get an idea about the weight of the component in the range of +/-10%, which is very good in the early stage of development as well as about its size. This helps users to make well-informed decisions about feasibility and derive parameters enriching a dynamic model setup.

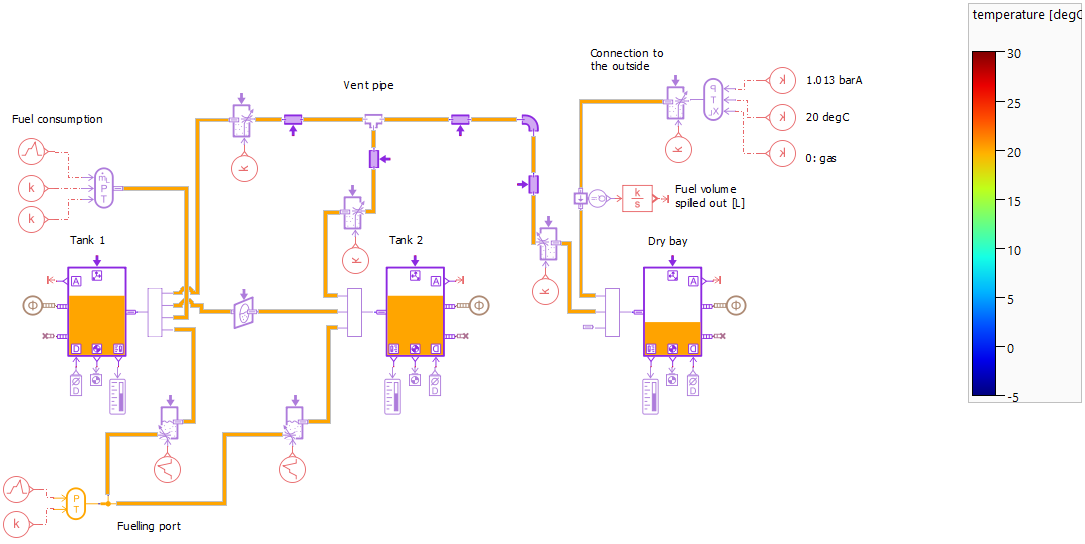

For fuel systems engineers or thermal analysts who need to evaluate the fuel temperature in every part of the system, the extension of the sketch animation with temperature-colored liquid in tanks in Simcenter Amesim offers a quick and easy way to visualize the results of the liquid level within a tank, along with its temperature. This makes the interpretation of the results even simpler and faster.

Marine

For performance and control engineers working in the marine industry, a new generic sensor has been added to get access to several variables related to the sea route (wind, wave, current amplitudes, and directions) or to key performance indicators like the speed over ground (SOG) or speed through water (STW). Users can now easily retrieve all of these variables and reuse them for their own computations or for setting up control laws and energy harvesting strategies.

Libraries and components

Hydraulics

In the hydraulics domain, there are two new features that deserve to be highlighted.

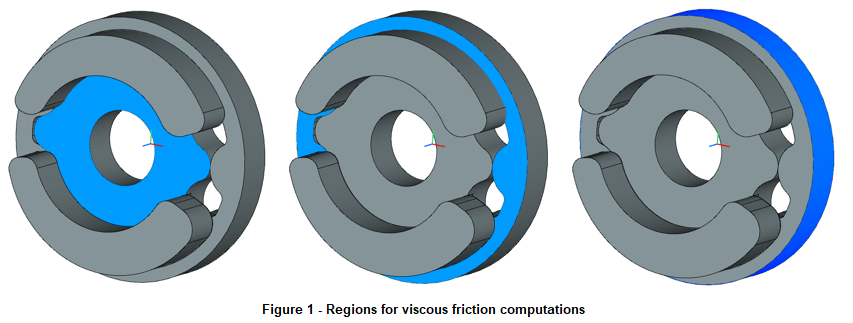

For pump suppliers or OEMs who need to design gerotor pumps or integrate them into their systems (for example when used as electric oil pumps in battery electric vehicles), the added viscous friction in gerotor pumps allows to predict the efficiency of gerotor pumps under various operating conditions, which are subject to high requirements. With this feature, the models allow a detailed simulation of various configurations and therefore the optimization of various geometric parameters of the pump with respect to the overall efficiency.

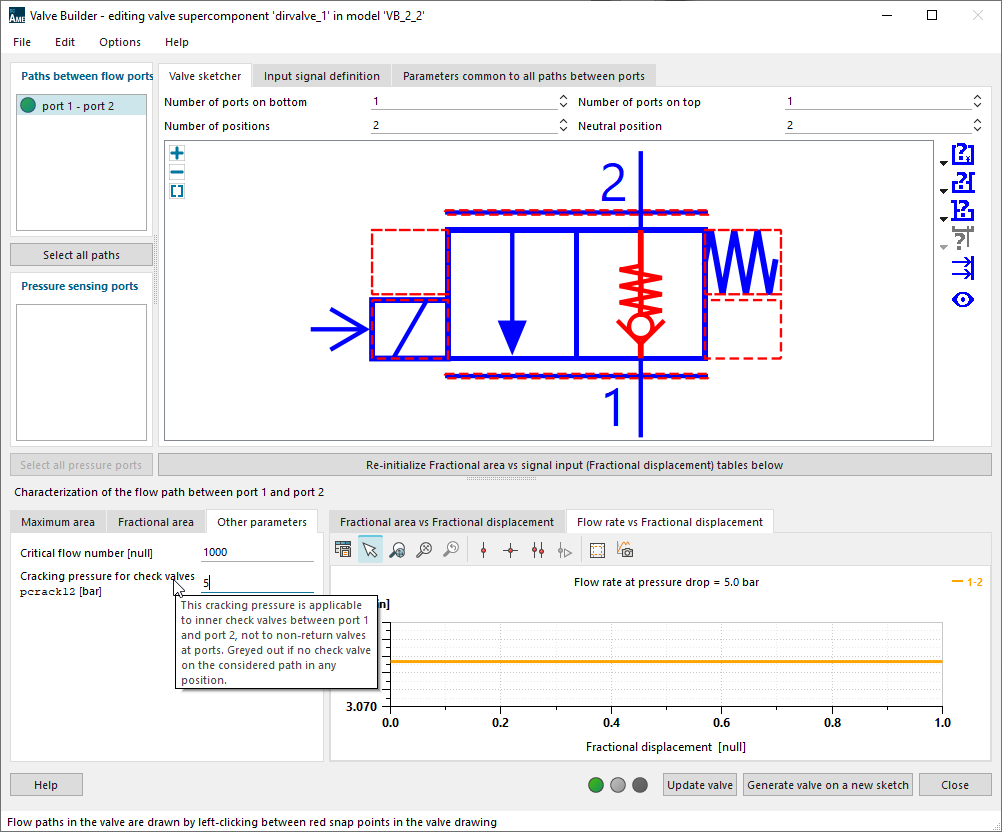

The valve-builder in Simcenter Amesim 2404 now offers the possibility to include pre-charged check valves in directional valves. This means that modeling poppet-type directional valves is much easier.

Thermal and thermo-fluids

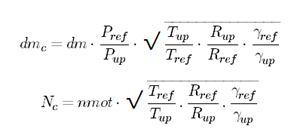

Engineers using two-phase flow compressors in hydrogen systems, might recognize that these compressors are rarely characterized with hydrogen but more often with air. The new compressor mass flow rate correction in Simcenter Amesim 2404 makes this characterization independent of the fluid. This means that the map derived from air can now be used with hydrogen gas.

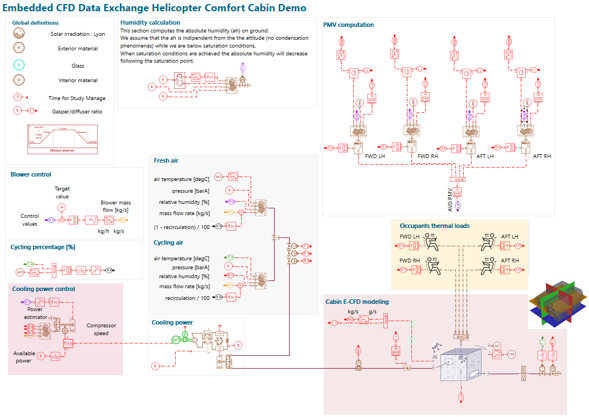

When assessing thermal management of a cabin, the internal airflow cannot be captured by system simulation but is calculated using Simcenter StarCCM+. The new embedded CFD data exchange in Simcenter Amesim 2404 offers the capability to import the result, select the desired 1D discretization, and automate the 1D sketch creation. This results in a transient, independent system simulation model connected with the full HVAC system and used for passenger comfort assessments. This model can run within seconds or minutes while embedding the full geometry and the complex flow captured by CFD.

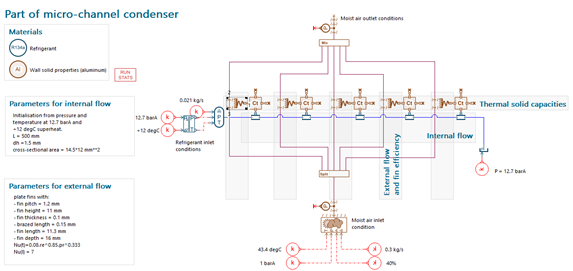

For users working on heat exchangers and not using the two-phase flow library, a new simplified fin heat exchange component has been added to the thermal library. This component is accessible to more users, easier to use and leaves less room for mistakes.

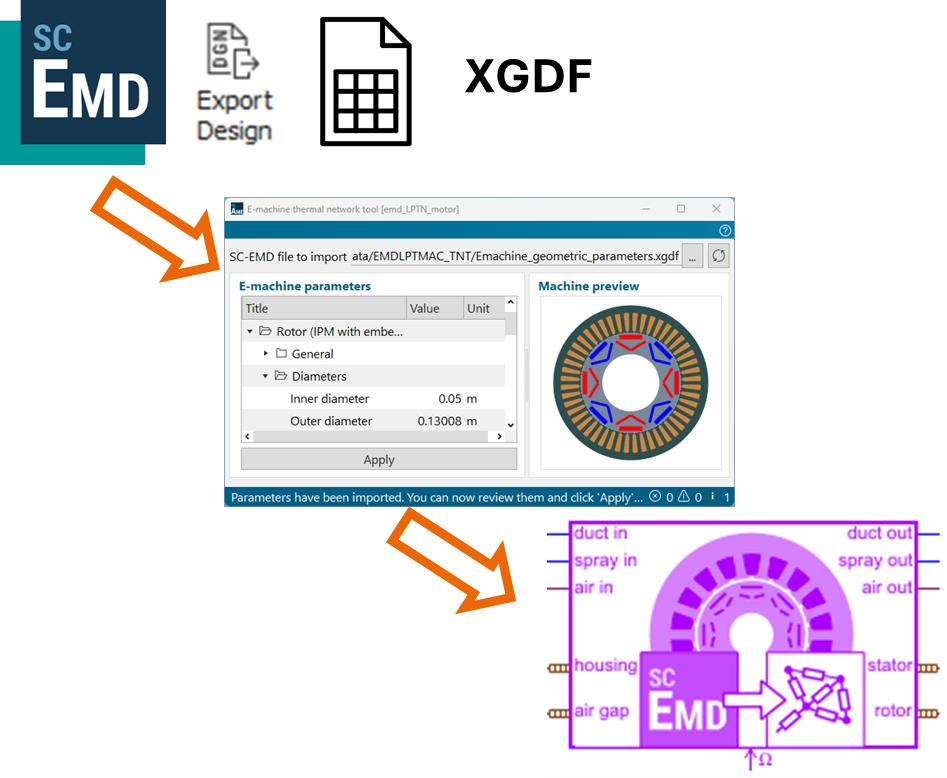

Electronics

The new e-machine thermal network, in addition to the e-machine thermal network tool, offers an accurate and automatic process to quickly set up an electro-thermal model of an e-machine with its cooling system. With this physics-based modeling approach, engineers will need much less error-prone manual steps to set up the e-machine electro-thermal model and focus on the thermal performance of the motor, identifying potential hotspots, designing effective cooling systems, or evaluating derating algorithms.

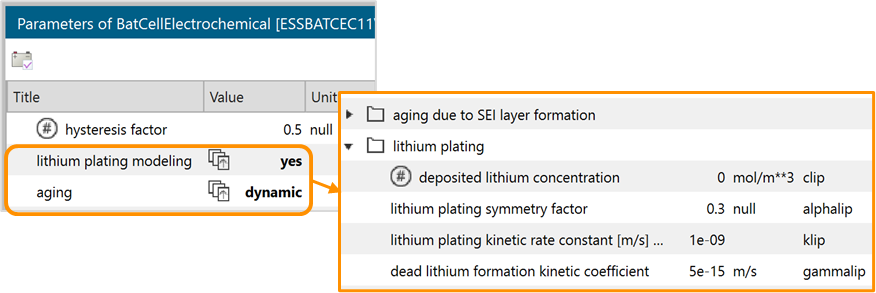

For battery pack designers and OEM integrators who need to consider accurate battery performance and aging as early as possible in their system design the new pseudo-2D (P2D) battery electrochemical model and the addition of the Li-plating aging into the single particle model with electrolyte (SPMe) electrochemical model in Simcenter Amesim 2404 offers a quicker and more accurate way to respond to rapid battery cell design iterations. Using this physics-based modeling approach engineers will need less test data to set up the model parameters while reaching a high-level of accuracy for battery pack performance and aging assessments.

Conclusion

Simcenter systems simulation release 2404 offers again a new set of useful features for engineers dealing with complex and integrated development challenges. The latest release is now available for download on our Support Center.

Read here the blog about the new Formula Student demonstrator, part of Simcenter Amesim 2404