Femap helps hydraulic power manufacturer Hydrauvision to reduce prototypes by 80%

Hydrauvision was founded in 1973 and is headquartered in Schoondijke, Netherlands. Hydrauvision specializes in producing hydraulic, pneumatic and mechanical drives and systems for a variety of industries, including industrial machinery and heavy equipment, petrochemical offshore, and marine.

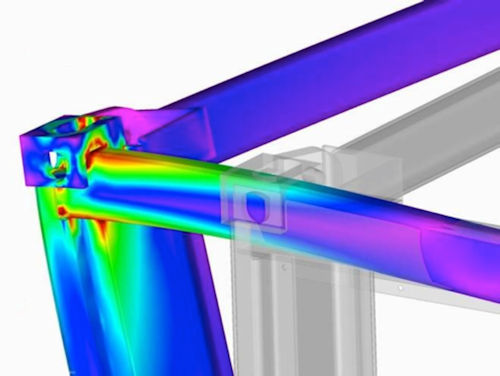

Hydrauvision typically connects multiple hydraulic units to a 20-foot ISO container frame. The structural and certification demands for this unit are high and include an offshore lifting appliance, integrated heavy pad eyes, load tests and certified materials. The cases also have to be stackable up to 10 containers high and it’s required that the primary structure not include side sections or roof panels.

The company used Solid Edge to design the container, and Femap to perform stress calculations. All required loading conditions were simulated accurately so that only a single physical test was required to achieve the Convention for Save Containers (CSC) certification. Previously, prior to using design and simulation software, as many as five prototypes were required to be built and tested.

Using Femap Hydrauvision was able to fully understand the issues of stress and loading on the structure and realize an 80% reduction in physical prototypes. A test performed at Lloyds Register on an offshore container, the deformation predicted by Femap came to within one-tenth of a millimeter of the physical test, helping to expedite the container approval certification.

You can read the full case study or watch the video case study and see how Hydrauvision used Femap with NX Nastran to realize an 80% reduction in physical prototypes.