NX CAE Structural Analyses Helps Haidlmair Improve Products

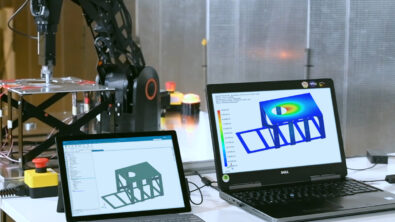

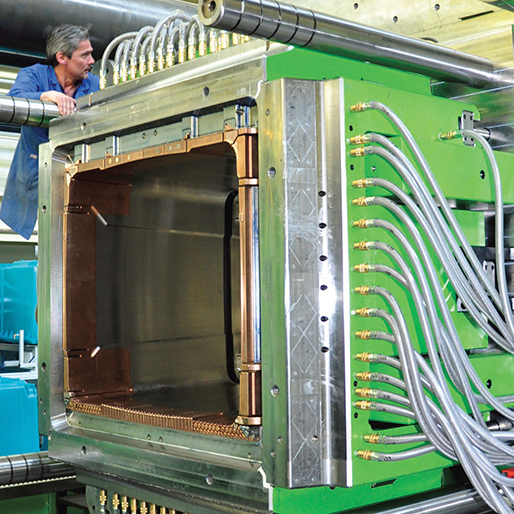

Haidlmair has used NX CAE for some time to generate the nets used in mold flow calculations, but now they also ensure handles or corners in crates and containers are strong enough to withstand expected loads via structural analyses with NX CAE.

Challenges:

Design and manufacture precision molds

Meet restrictive lead time requirements

Eliminate quality risks

Prevent data misinterpretation

Enhance NC programming accuracy

Keys To Success:

NX CAM for NC programming work

NX CAD and Mold Wizard for design process automation

Teamcenter for all design and manufacturing data and process management

Manufacturing Resource Library for cutting tool management

Results:

Reduced design cycles

Eliminated data conversion errors

Streamlined information flow to shop floor

Unified procedures and workflows

Improved process stability

Shortened lead times

Industry:

Industrial Machinery & Heavy Equipment

Client’s Primary Business:

Haidlmair is the parent company in a group of 8 companies in 5 countries. The core business of the parent plant in Nussbach, Austria, is the production of injection molds with a focus on the full range of containers, supplemented by technical and automotive parts. The other companies in the Haidlmair group build thermoforming and stretch blow molds for the production of medical and packaging parts as well as automation solutions and extrusion dies for the production of files and sheets.

Solutions/Services:

Client Location:

Nussbach

Austria

Read the entire case study!